Efficient integrated water purification equipment polymer and CNTs composite filter material for sewage treatment and preparation method of material

A polymer material, composite filtration technology, applied in water/sewage treatment, water/sludge/sewage treatment, single-component synthetic polymer rayon, etc., can solve the problem that the reverse osmosis treatment unit cannot operate normally, abnormal mechanics, Electrical and magnetic properties, dealing with the limitation of pollutant types, etc., to achieve the effects of various bonding methods, long service life and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add the SWCNTs material and MWCNTs material to the mixed acid of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1 according to the mass ratio of 1:1, ultrasonically oscillate for 2 hours, suck out the mixed acid liquid, add deionized water to dilute, and dry the filtered CNTs 13h. Add 10g of modified CNTs material after oxidation treatment to 8mL N-N dimethylformamide and 220mL thionyl chloride solution, CNTs (g): N-N dimethylformamide (mL): thionyl chloride (mL) =5:4:110, remove the unreacted thionyl chloride after magnetic stirring for 36 hours, then dry the CNTs for 13 hours, add the above CNTs and aliphatic polyester amine into the reaction kettle, pass nitrogen gas to prevent oxidation, and raise the temperature to 250-280 ℃, after 6 hours of polymerization reaction, the composite material is obtained, and finally the fiber filament with a diameter of 5-70um is made by melt spinning. Through the method of fiber filament constructi...

Embodiment 2

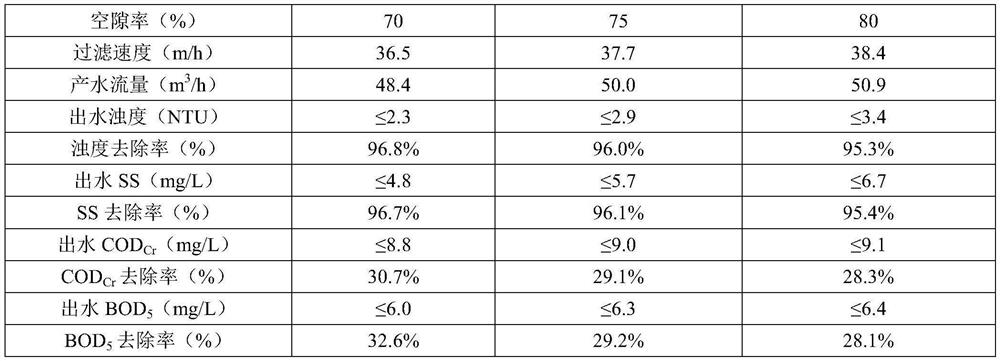

[0034]The MWCNTs material was added to a mixed acid of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1, ultrasonically oscillated for 2 hours, the mixed acid liquid was sucked out, diluted with deionized water, and the filtered CNTs were dried for 13 hours. Add 10 g of oxidized CNTs to 8 mL N-N dimethylformamide and 220 mL thionyl chloride solution, remove unreacted thionyl chloride after magnetic stirring for 36 h, then dry the CNTs for 13 h, and mix the above CNTs with polyvinylidene fluoride Add ethylene into the reaction kettle, pass nitrogen to prevent oxidation, raise the temperature to 250-280°C, and polymerize for 6 hours to obtain composite materials, and finally melt-spin to make fibers with a diameter of 5-70um. Through fiber filament construction, combination and stacking methods, the ratios of polymer materials and modified CNTs materials are 97:3, 97.5:2.5, 98:2, 98.5:1.5, the pore size is 0.1um, and the porosity is 75%, polymer...

Embodiment 3

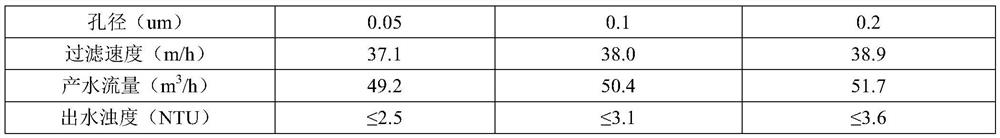

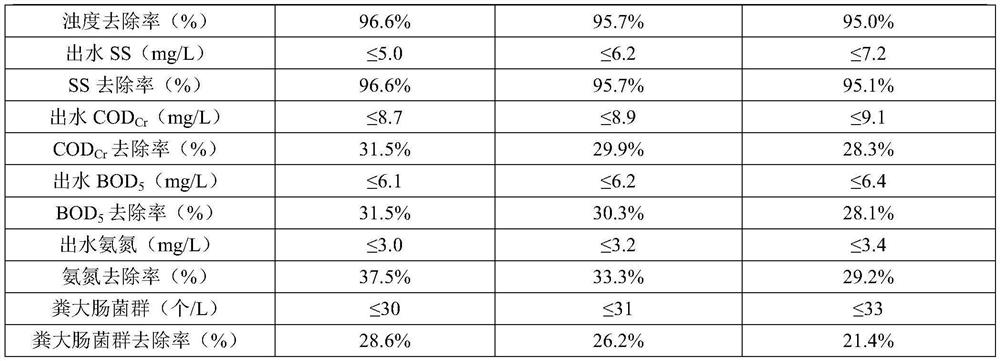

[0038] The SWCNTs material was added to the mixed acid of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1, ultrasonically oscillated for 2 hours, the mixed acid liquid was sucked out, diluted with deionized water, and the filtered CNTs were dried for 13 hours. Add 10 g of oxidized CNTs to 8 mL N-N dimethylformamide and 220 mL thionyl chloride solution, remove unreacted thionyl chloride after magnetic stirring for 36 h, then dry the CNTs for 13 h, mix the above CNTs with polyether ketone Put it into the reaction kettle, blow nitrogen to prevent oxidation, raise the temperature to 250-280°C, and after 6 hours of polymerization reaction, the composite material is obtained, and finally the fiber filament with a diameter of 5-70um is made by melt spinning. Through the fiber filament construction, combination and superposition method, the ratio of polymer material and modified CNTs material is 97.5:2.5, the pore diameter is 0.05um, 0.1um, 0.2um, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com