Multilayer fiber composite filter material

A multi-layer fiber and multi-layer composite technology, which is applied in the field of multi-layer fiber composite filter elements and multi-layer fiber composite filter materials, can solve the problems of single filtering effect and affecting filtering effect, so as to increase the amount of dirt held, increase the cost of use, non-deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

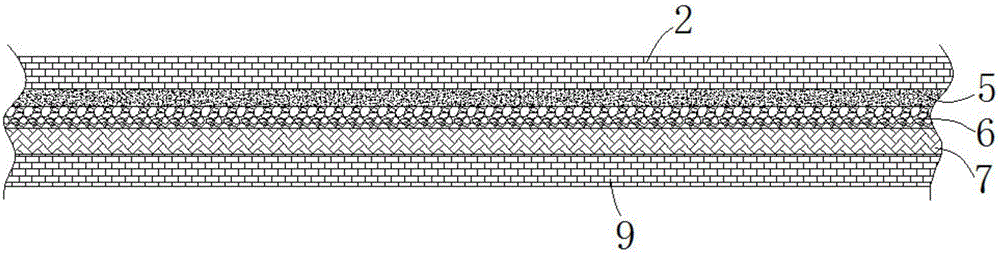

Embodiment 1

[0033] Such as figure 1 As shown, a multilayer fiber composite filter material described in the embodiment of the present invention, the multilayer composite filter material 1 is provided with an inner support layer 2, a polypropylene superfine fiber layer 5, a fine fiber glass layer in sequence from the inside to the outside. Fiber layer 6, coarse fiber glass fiber layer 7, outer support layer 9, wherein the mesh number range of the polypropylene superfine fiber layer is 20 μm-50 μm, and the mesh number range of the fine fiber glass fiber layer is 1 μm-50 μm, The mesh number of the thick fiber glass fiber layer ranges from 5 μm to 100 μm; the inner support layer and the outer support layer are both 4 mesh to 200 mesh metal mesh, wherein the mesh number of the inner support layer is greater than the mesh number of the nylon braided mesh layer , the mesh number of the outer support layer is greater than the mesh number of the coarse fiber glass fiber layer.

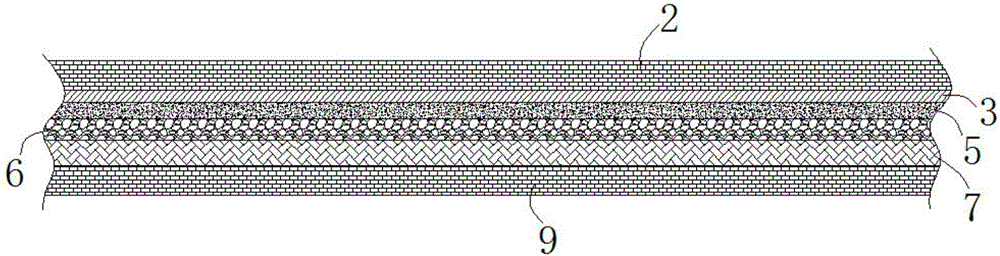

Embodiment 2

[0035] Such as figure 2 As shown, a multi-layer fiber composite filter material described in the embodiment of the present invention, the multi-layer composite filter material 1 is provided with an inner support layer 2, a nylon braided mesh layer 3, and a polypropylene ultrafine fiber in sequence from the inside to the outside. Layer 5, fine fiber glass fiber layer 6, thick fiber glass fiber layer 7, outer support layer 9, wherein the mesh number range of the polypropylene superfine fiber layer is 20 μm-50 μm, and the mesh number of the fine fiber glass fiber layer The range is 1 μm-50 μm, and the mesh number range of the thick fiber glass fiber layer is 5 μm-100 μm; the inner support layer and the outer support layer are both 4 mesh-200 mesh metal mesh, and the mesh number of the inner support layer is larger than that of nylon The mesh number of the braided mesh layer, the mesh number of the outer support layer is greater than the mesh number of the thick fiber glass fiber...

Embodiment 3

[0037] Such as image 3 As shown, a multi-layer fiber composite filter material described in the embodiment of the present invention, the multi-layer composite filter material 1 is provided with an inner support layer 2, a nylon braided mesh layer 3, and an antistatic protective layer 4 in sequence from the inside to the outside. , polypropylene ultrafine fiber layer 5, thin fiber glass fiber layer 6, thick fiber glass fiber layer 7, outer support layer 9, wherein the mesh number range of the polypropylene ultrafine fiber layer is 20 μm-50 μm, and the fine fiber The mesh number range of the glass fiber layer is 1 μm-50 μm, and the mesh number range of the thick fiber glass fiber layer is 5 μm-100 μm; the inner support layer and the outer support layer are both 4 mesh-200 mesh metal mesh, wherein the inner support The mesh number of the layer is larger than that of the nylon braided mesh layer, and the mesh number of the outer support layer is larger than that of the thick fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com