Helical flow dephosphorization reactor

A reactor and spiral technology, which is applied in the field of spiral flow phosphorus removal reactor, can solve the problems of work efficiency limitation, etc., and achieve the effect of improving performance, improving filtration efficiency, and uniform water distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

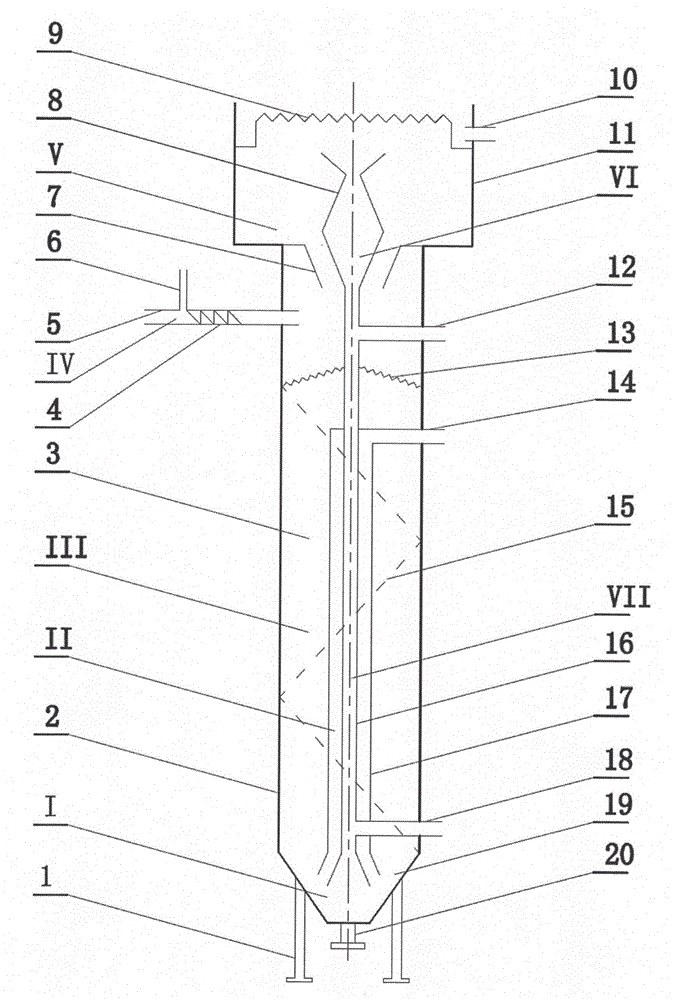

[0046] figure 1It is a schematic diagram of the spiral flow phosphorus removal reactor provided by the present invention, and the spiral flow phosphorus removal reactor is respectively from bottom to top the area to be backwashed I, the lifting area VII, the water outlet area II, the filtration area III, and the water inlet area IV, backwash zone VI, solid-liquid separation zone V.

[0047] The area I to be backwashed includes an inverted body 19, the center of which is below the inverted body 19 is provided with a vent pipe 20, and the outside is provided with a leg 1.

[0048] The airlift ascending zone VII includes the airlift tube 16, the bottom of the airlift tube 16 is provided with a bell mouth, and the bottom surface of the bell mouth is parallel to the bottom surface of the zone I to be backwashed, and the distance betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com