Preparation method of monodisperse oil-phase nano barium sulfate dispersion

A nano barium sulfate and dispersion technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of small agglomeration, insufficient dispersibility, not monodisperse state, etc., and achieve mild process conditions and low price. , the effect of short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

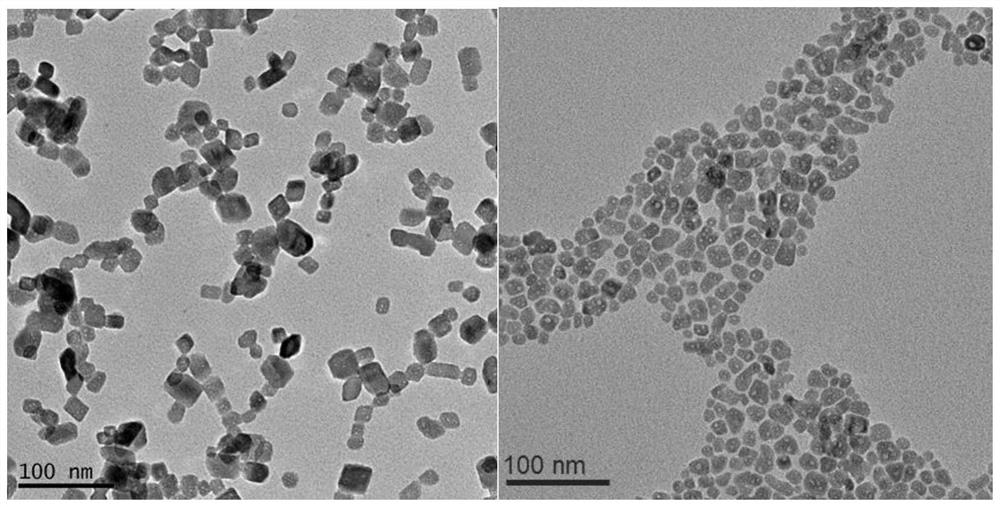

[0043] As an aspect of the present invention, a kind of preparation method of monodisperse oil phase nano barium sulfate dispersion of the present invention, comprises the steps:

[0044] S1. Dissolving modifier A and barium compound in solvent A simultaneously to obtain solution A;

[0045] S2, dissolving the sulfate ion-containing compound in solvent B to obtain solution B;

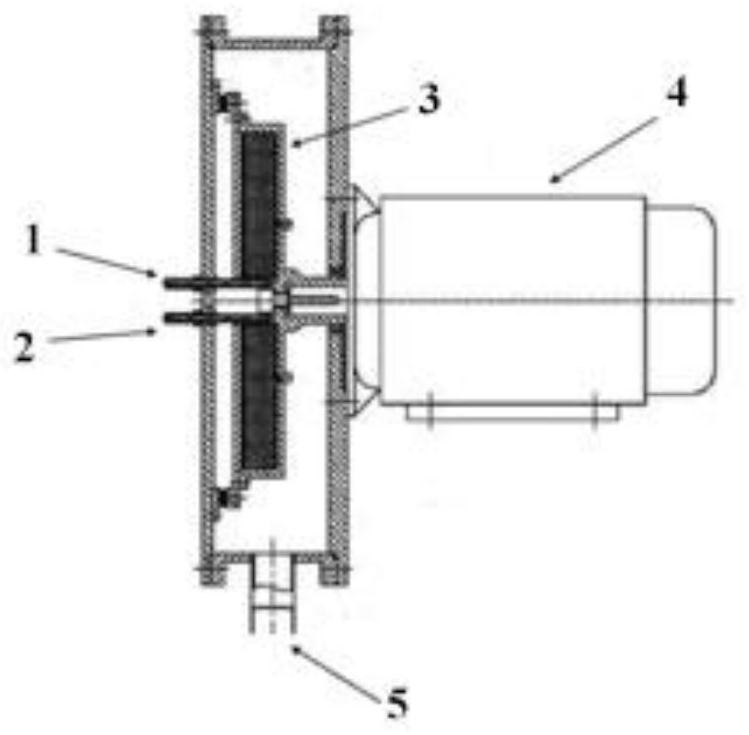

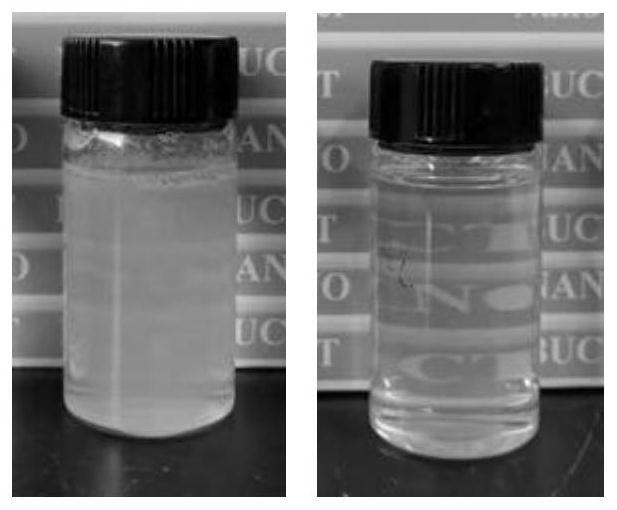

[0046] S3. Inject solution A and solution B into the high-gravity rotating packed bed through the feed port at the same time, so that the two liquids are fully mixed in the rotating bed to obtain nano-barium sulfate slurry through the discharge port, and then the nano-barium sulfate slurry The material is transferred to the reaction vessel and heated to the modification temperature to carry out the modification reaction; after the modification is completed, the slurry is centrifugally washed, and the obtained filter cake is dispersed in water to obtain a water-phase nano barium sulfate dispersion;

[0...

Embodiment 1

[0064] A kind of preparation method of monodisperse oil phase nano barium sulfate dispersion, comprises the steps:

[0065] 1) Add 20% mass modifier stearic acid of theoretically obtained barium sulfate product to 0.05mol / L barium chloride methanol solution and stir to dissolve. Simultaneously, the concentrated sulfuric acid methanol solution of preparation 0.05mol / L concentration;

[0066] 2) Turn on the supergravity rotating packed bed and adjust the speed to 1500rpm; keep the temperature environment of the supergravity rotating packed bed at 50°C by heating in a circulating water bath; turn on the feed pump to control the feed rate of the barium chloride methanol solution containing stearic acid The feeding rate of concentrated sulfuric acid methanol solution is 100mL / min, and the feed rate of concentrated sulfuric acid methanol solution is 100mL / min; the barium chloride methanol solution containing stearic acid and the concentrated sulfuric acid methanol solution are simul...

Embodiment 2

[0076] A kind of preparation method of monodisperse oil phase nano barium sulfate dispersion, comprises the steps:

[0077] 1) Add 30% mass modifier lauric acid of the theoretically obtained barium sulfate product into an aqueous barium chloride solution with a concentration of 0.06mol / L and stir for dissolution. Simultaneously, the concentrated sulfuric acid aqueous solution of preparation 0.06mol / L concentration;

[0078] 2) Turn on the supergravity rotating packed bed and adjust the rotating speed to 2500rpm; keep the temperature environment of the supergravity rotating packed bed at 60°C by heating in a circulating water bath; turn on the feed pump and control the feed rate of the barium chloride aqueous solution containing stearic acid to 100mL / min, the feeding rate of concentrated sulfuric acid aqueous solution is 100mL / min; the barium chloride aqueous solution containing stearic acid and the concentrated sulfuric acid aqueous solution are simultaneously transported to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com