A post-cleanable ultra-low density transparent silica airgel and its preparation method and application

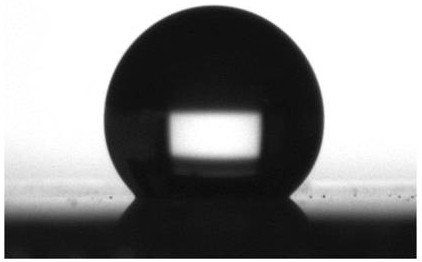

An ultra-low density, silicon dioxide technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of space dust capture final results analysis interference, affecting the cleanliness and transparency of aerogels, etc., to overcome hydrophobicity. The effect of reducing unevenness and simplifying process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In a first aspect, the present invention provides a method for preparing post-cleanable ultra-low-density transparent silica aerogel, the method comprising the steps of:

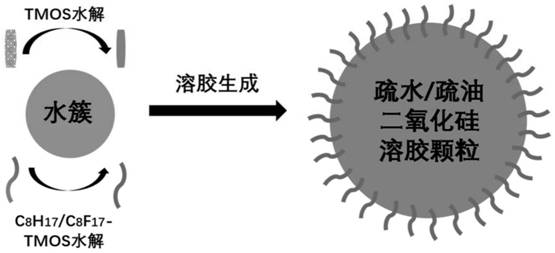

[0033] (1) Use the first organic solvent to mix methyl orthosilicate (TMOS), citric acid and water evenly to obtain the first reaction system, which is subjected to pre-hydrolysis and distillation in sequence to obtain the precursor liquid A: In the present invention, for example, use the first organic solvent to mix methyl orthosilicate (TMOS), citric acid and water uniformly, carry out pre-hydrolysis reaction at 50-70°C for 12 hours, and completely distill out at 80°C The methanol produced by the pre-hydrolysis of the first organic solvent and methyl orthosilicate to obtain precursor liquid A; The methanol generated by pre-hydrolysis is the end point;

[0034] (2) Mix the precursor liquid A, long-chain alkyl trimethoxysilane, perfluoro long-chain alkyl trimethoxysilane and polyvinylpyrrolidone unif...

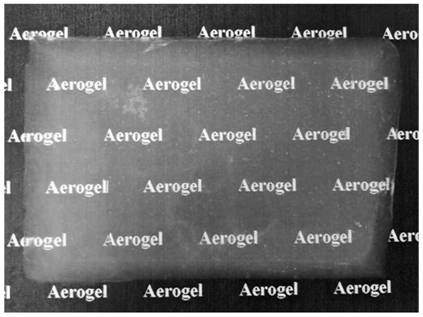

Embodiment 1

[0059] ①Add 15.2g of methyl orthosilicate (0.1mol), citric acid (0.004mol), 5.4g of water (0.3mol), 9.6g of methanol (0.3mol) into a single-necked flask, stir and mix evenly, and heat up to 60 °C, reflux reaction (pre-hydrolysis reaction) at this temperature for 12 hours, change the reflux device to a distillation device, raise the temperature to 80 °C, and completely distill the methanol in the reaction liquid to obtain the precursor liquid A, each group in the precursor liquid A The molar ratio of raw materials is methyl orthosilicate: citric acid: water: methanol is 1:0.04:3:3.

[0060]②Add 10.5g decyltrimethoxysilane (0.04mol), 2.3g perfluorodecyltrimethoxysilane (0.004mol), 7.2g polyvinylpyrrolidone (molecular weight 24kDa, 0.0003mol), 105.6g of n-amyl alcohol (1.2mol), magnetic stirring and mixing, heating up to 60°C, reflux reaction (pre-hydrolysis reaction) at this temperature for 2h, to obtain a mixed solution B, the raw materials of each component in the mixed soluti...

Embodiment 2

[0066] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0067] In step ①, add 15.2g of methyl orthosilicate (0.1mol), citric acid (0.001mol), 3.6g of water (0.2mol), 9.6g of methanol (0.3mol) into the single-necked flask respectively, stir and mix well , heat up to 60°C, reflux reaction (pre-hydrolysis reaction) at this temperature for 12 hours, change the reflux device to a distillation device, raise the temperature to 80°C, and completely distill the methanol in the reaction solution to obtain the precursor liquid A, the precursor liquid The raw materials of each component in A are based on the molar ratio of methyl orthosilicate: citric acid: water: methanol is 1:0.01:2:3.

[0068] In step ②, add 5.25g decyltrimethoxysilane (0.02mol), 1.15g perfluorodecyltrimethoxysilane (0.002mol), 2.4g polyvinylpyrrolidone (molecular weight 24kDa, 0.0001mol), 105.6g n-amyl alcohol (1.2mol), magnetic stirring and mixing, heating up to 60°C, reflux reaction (pre-hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com