Preparation method of high-magnification quick-charging graphite negative electrode material

A graphite anode, high-rate technology, applied in battery electrodes, structural parts, electrical components, etc., can solve problems such as the impact of battery safety issues, lithium precipitation, etc., to improve the rate and fast charging performance, improve the conductive network, and electron transmission speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

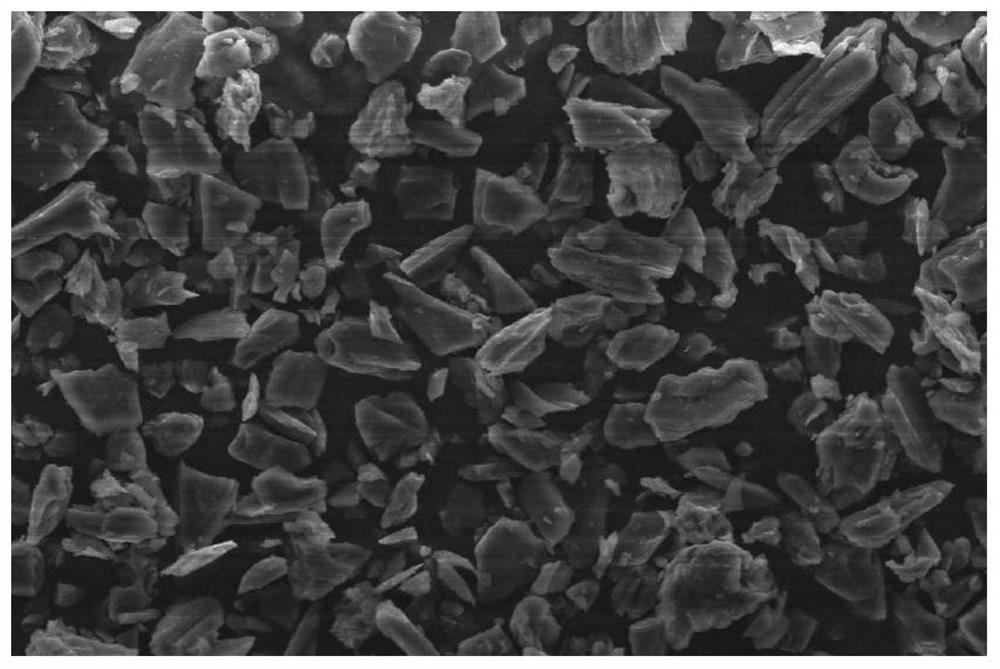

Image

Examples

Embodiment 1

[0029] A method for preparing a high-rate fast-charging graphite negative electrode material, comprising the following steps:

[0030] S1. One or more of needle coke, petroleum coke and pitch coke are coarsely crushed and finely ground, and then spheroidized to obtain graphite raw material powder;

[0031] S2, mixing the graphite raw material powder described in step S1 with the first carbon source, heating to a certain temperature in an inert atmosphere for surface coating, and obtaining the first carbon source coated graphite raw material after cooling;

[0032] S3. Carrying out high-temperature carbonization of the first carbon source-coated graphite raw material described in step S2 in an inert atmosphere, and obtaining a primary carbonized material after cooling;

[0033] S4, subjecting the primary carbonized material described in step S3 to high-temperature graphitization treatment, and obtaining artificial graphite powder after cooling;

[0034] S5, mixing the artifici...

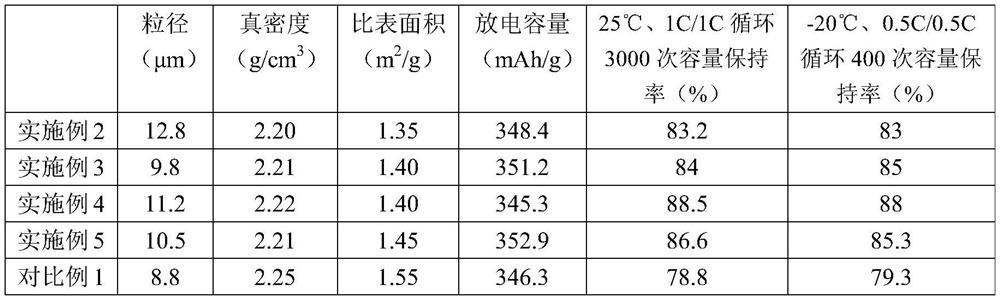

Embodiment 2

[0037] A method for preparing a high-rate fast-charging graphite negative electrode material, comprising the following steps:

[0038] S1. Coarsely pulverize the raw needle coke (moisture content is 3%, ash content is 10%) through a jet mill until the particle size distribution D50 is 20-25 μm, and then finely grind it with an ultrafine mill until the particle size distribution D50 is 6 -9 μm, and then use a spheroidizer to perform spheroidization and shaping treatment until the particle size distribution D50 is 5-8 μm to obtain graphite raw material powder;

[0039] S2. Mix the graphite raw material powder obtained in step S1 with pitch coke at a mass ratio of 95:5. In an argon / nitrogen mixed atmosphere, first raise the temperature to 180°C at a heating rate of 2°C / min, keep it warm for 1h, and then Raise the temperature to 280°C at a heating rate of 1.5°C / min, hold for 70 minutes to soften and coat, and then cool to room temperature at a cooling rate of 1.5°C / min to obtain p...

Embodiment 3

[0045] A method for preparing a high-rate fast-charging graphite negative electrode material, comprising the following steps:

[0046] S1. Raw needle coke (moisture content is 3%, ash content is 10%) is coarsely pulverized through a jet mill until the particle size distribution D50 is 20-25 μm, and then finely ground through an ultrafine mill until the particle size distribution D50 is 6 -9 μm, and then use a spheroidizer to perform spheroidization and shaping treatment until the particle size distribution D50 is 5-8 μm to obtain graphite raw material powder;

[0047] S2. Mix the graphite raw material powder obtained in step S1 with pitch coke at a mass ratio of 95:5. In an argon / nitrogen mixed atmosphere, first raise the temperature to 190° C. at a heating rate of 3° C. / min, keep it warm for 30 minutes, and then Raise the temperature to 300°C at a heating rate of 2°C / min, keep warm for 1h to soften and coat, and then cool to room temperature at a cooling rate of 1.5°C / min to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com