A kind of polyurethane and preparation method thereof

A polyurethane and polyester polyol technology, applied in the field of elastomers, can solve the problems of complex post-processing, three wastes, and no industrialization, and achieve the effect of reducing waste and solving white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

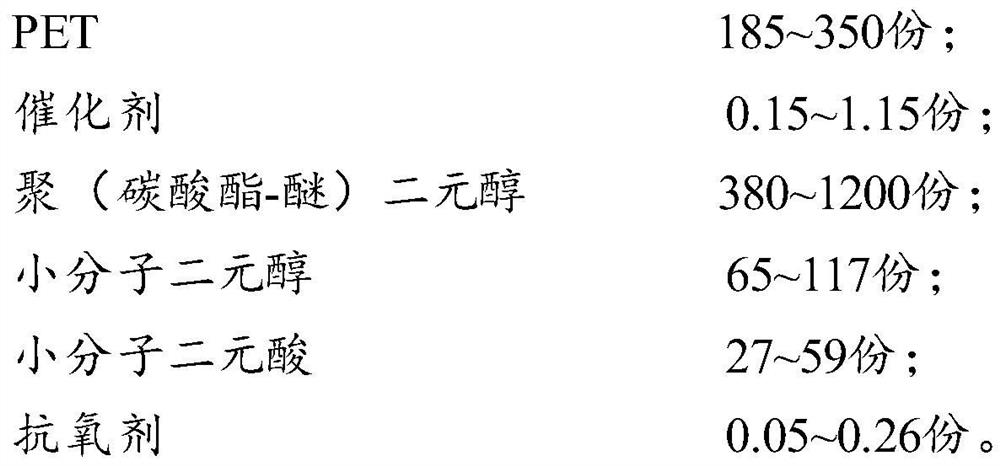

[0041] In the present invention, the preparation method of described PET polyester polyol preferably comprises:

[0042] Carrying out the first reaction of PET, poly(carbonate-ether) glycol, small molecule glycol, catalyst and antioxidant to obtain an intermediate;

[0043] The intermediate and the small molecule dibasic acid are subjected to a second reaction to obtain polyester polyol.

[0044] In the present invention, the type and amount of the PET, poly(carbonate-ether) glycol, small molecule glycol, catalyst, antioxidant and small molecule dibasic acid are consistent with those described in the above-mentioned technical scheme. This will not be repeated here.

[0045]In the present invention, the first reaction is preferably carried out under the protection of nitrogen. In the present invention, the first reaction preferably includes:

[0046] After raising the temperature of PET, poly(carbonate-ether) glycol, small molecule glycol, catalyst and antioxidant to 130-170...

Embodiment 1

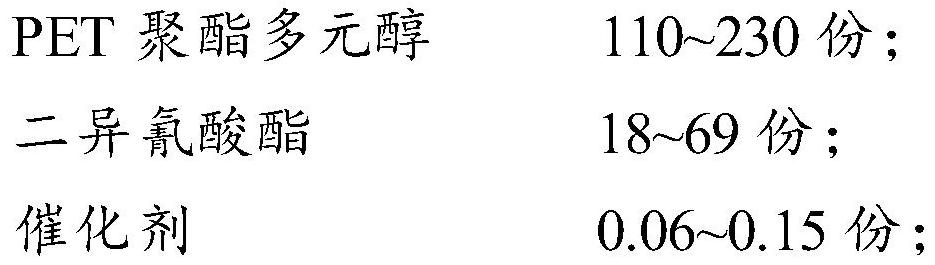

[0071] The synthesis of embodiment 1 polyurethane

[0072] Weigh 110g of PET polyester polyol and put it into a reaction kettle, heat to 80°C, depressurize for 3 hours, add 18g of toluene diisocyanate, react for 4 hours to obtain a reaction product;

[0073] Add 0.06g of stannous octoate and 0.68g of IRGANOX1076 to the reactor, and continue to react with the above reaction product for 2 hours to obtain an intermediate product;

[0074] Raise the temperature of the reactor to 140° C., add 4.2 g of 1,3-propanediol, react with the above-mentioned intermediate product for 2 hours, and discharge to obtain polyurethane.

Embodiment 2

[0075] The synthesis of embodiment 2 polyurethane

[0076] Weigh 230g of PET polyester polyol and put it into a reaction kettle, heat to 120°C, depressurize for 1 hour, add 69g of dicyclohexylmethane diisocyanate, and react for 1 hour to obtain a reaction product;

[0077] Add 0.15g of dibutyltin dilaurate and 4.5g of IRGANOX1010 into the reaction kettle, and continue to react with the above reaction product for 1 hour to obtain an intermediate product;

[0078] Raise the temperature of the reactor to 170° C., add 16 g of 1,4-butanediol, react with the above-mentioned intermediate product for 0.5 hour, and discharge to obtain polyurethane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com