Bicycle rim anti-corrosion process

A technology for bicycles and rims, applied in the direction of fireproof coatings, coatings, pre-treated surfaces, etc., can solve the problems of bicycle rims without anti-corrosion effect, poor spraying effect of anti-corrosion process, and poor wear-resistant effect of coatings, etc. Achieve the effect of facilitating large-scale production, improving hydrophobic effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

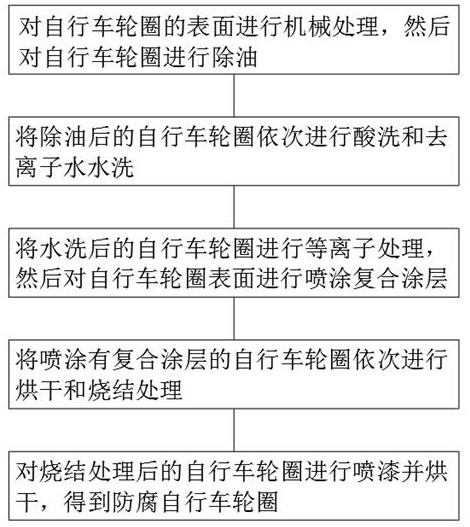

Image

Examples

Embodiment 1

[0025] A bicycle rim anticorrosion process, comprising the following steps:

[0026] (1) Mechanically treat the surface of the bicycle rim, and then degrease the bicycle rim;

[0027] The step of the mechanical treatment on the surface of the bicycle rim is to use emery wheel to polish the surface of the bicycle rim, then to polish the bicycle rim with 1200 mesh sandpaper, and finally to polish the bicycle rim with 2000 mesh sandpaper;

[0028] When degreasing the bicycle rim, place the bicycle rim in a mixed solution of gasoline and 5% sodium hydroxide for immersion. The immersion temperature is 55°C, soak for 12 minutes, and send the bicycle rim to the ultrasonic cleaning machine after soaking Ultrasonic cleaning was carried out in the medium, and the ultrasonic cleaning was performed for 10 minutes.

[0029] (2) The degreased bicycle rims are pickled and washed with deionized water in sequence;

[0030] Nitric acid solution is used for pickling, pickling at room temperatu...

Embodiment 2

[0039] A bicycle rim anticorrosion process, comprising the following steps:

[0040] (1) Mechanically treat the surface of the bicycle rim, and then degrease the bicycle rim;

[0041] The step of the mechanical treatment on the surface of the bicycle rim is to use emery wheel to polish the surface of the bicycle rim, then to polish the bicycle rim with 1200 mesh sandpaper, and finally to polish the bicycle rim with 2000 mesh sandpaper;

[0042] When degreasing the bicycle rim, place the bicycle rim in a mixed solution of gasoline and 5% sodium hydroxide for immersion. The immersion temperature is 55°C, soak for 12 minutes, and send the bicycle rim to the ultrasonic cleaning machine after soaking Ultrasonic cleaning was carried out in the medium, and the ultrasonic cleaning was performed for 10 minutes.

[0043] (2) The degreased bicycle rims are pickled and washed with deionized water in sequence;

[0044] Nitric acid solution is used for pickling, pickling at room temperatu...

Embodiment 3

[0053] A bicycle rim anticorrosion process, comprising the following steps:

[0054] (1) Mechanically treat the surface of the bicycle rim, and then degrease the bicycle rim;

[0055] The step of the mechanical treatment on the surface of the bicycle rim is to use emery wheel to polish the surface of the bicycle rim, then to polish the bicycle rim with 1200 mesh sandpaper, and finally to polish the bicycle rim with 2000 mesh sandpaper;

[0056] When degreasing the bicycle rim, place the bicycle rim in a mixed solution of gasoline and 5% sodium hydroxide for immersion. The immersion temperature is 55°C, soak for 12 minutes, and send the bicycle rim to the ultrasonic cleaning machine after soaking Ultrasonic cleaning was carried out in the medium, and the ultrasonic cleaning was performed for 10 minutes.

[0057] (2) The degreased bicycle rims are pickled and washed with deionized water in sequence;

[0058] Nitric acid solution is used for pickling, pickling at room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com