Compound for restoring contaminated soil or contaminated water

A technology of polluted soil and compounds, applied in the restoration of polluted soil, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of difficult treatment, groundwater pollution, etc., and achieve strong heavy metal removal ability and formaldehyde removal ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

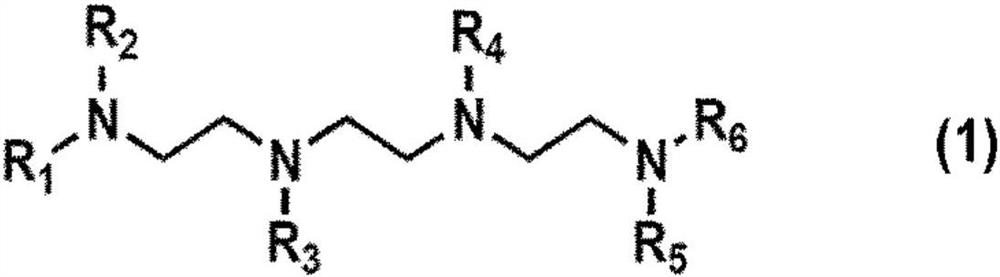

[0109] 3,6,9,12-tetrakis(carboxymethyl)-3,6,9,12-tetraazatetradecanedioic acid (3,6,9,12-tetrakis(carboxymethyl)-3,6,9 , the preparation of 12-tetraazatetradecanedioic acid) (chemical formula 1e)

[0110]

[0111] Add 10.0g of triethylenetetramine (Triethylenenetetramine) and 400.0ml of acetonitrile (ACN) and stir, add 66.1g of K 2 CO 3 And 78.8g of ethyl bromoacetate (Ethyl bromoacetate) was heated and refluxed and stirred for 48 hours, and then the reaction was terminated. After cooling to normal temperature, filter, and vacuum concentrate the filtrate after the waste gas is solid. After adding 200 ml of dichloromethane (MC) and 300 ml of purified water to the concentrate, it was stirred for 30 minutes and left to stand for layer separation. with MgSO 4 After working up the organic layer and concentrating in vacuo, column purification with MC-MeOH (MC-MeOH) afforded 29.6 g of 3,6,9,12-tetrakis(2-ethoxy-2-oxoethyl)-3 , 6,9,12-tetraazatetradecanedioate (Diethyl 3,6,9,1...

Embodiment 2

[0116] 4,4',4",4"'-(((ethane-1,2-diylbis((4-carboxyphenyl)azanediyl))bis(ethane-2,1-diyl ))bis(azanetriyl))tetrabenzoic acid (4,4',4",4"'-(((ethane-1,2-diylbis((4-carboxyphenyl)azanediyl))bis(ethane-2 , Preparation of 1-diyl))bis(azanetriyl))tetrabenzoic acid) (chemical formula 1f)

[0117]

[0118] 10.0 g of triethylenetetramine, 108.1 g of ethyl 4-bromobenzoate (ethyl4-bromobenzoate), 46.0 g of t-BuONa, and 600 ml of toluene were added and stirred. After heating up to 35°C, add 2.8g of 50% (t-Bu) 3 The P toluene solution was stirred for 30 minutes, then warmed up to 50° C., and then 2.0 g of Pd(dba) 2 was added. After the temperature was raised, the mixture was stirred under reflux, and then the reaction was terminated. After cooling to room temperature, 1000 ml of pure water was added, stirred for 30 minutes, left to stand for layer separation, and the water layer was discarded. with MgSO 4After working up the organic layer and concentrating in vacuo, column purifica...

Embodiment 3

[0123] 5,5'-((2-((5-carboxypyridin-3-yl)(2-((5-carboxypyridin-3-yl)(2-((5-carboxypyridin-3-yl)(2 -carboxypyridin-4-yl)amino)ethyl)amino)ethyl)amino)ethyl)azanediyl)nicotinic acid (5,5'-((2-((5-carboxypyridin-3-yl )(2-((5-carboxypyridin-3-yl)(2-((5-carboxypyridin-3-yl)(2-carboxypyridin-4-yl)amino)ethyl)amino)ethyl)amino)ethyl)azanediyl) Preparation of dinicotinicacid) (chemical formula 1g)

[0124]

[0125] 10.0 g of triethylenetetramine, 108.5 g of ethyl 5-bromonicotinate (5-bromonicotinate), 46.0 g of t-BuONa, and 600 ml of xylene (Xylene) were added and stirred. After heating up to 35°C, add 2.8g of 50% (t-Bu) 3 The P toluene solution was stirred for 30 minutes, then warmed up to 50° C., and then 2.0 g of Pd(dba) 2 was added. After the temperature was raised, the mixture was stirred under reflux, and then the reaction was terminated. After cooling to room temperature, 1000 ml of pure water was added, stirred for 30 minutes, left to stand for layer separation, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com