Porous radiation refrigeration film and preparation method thereof

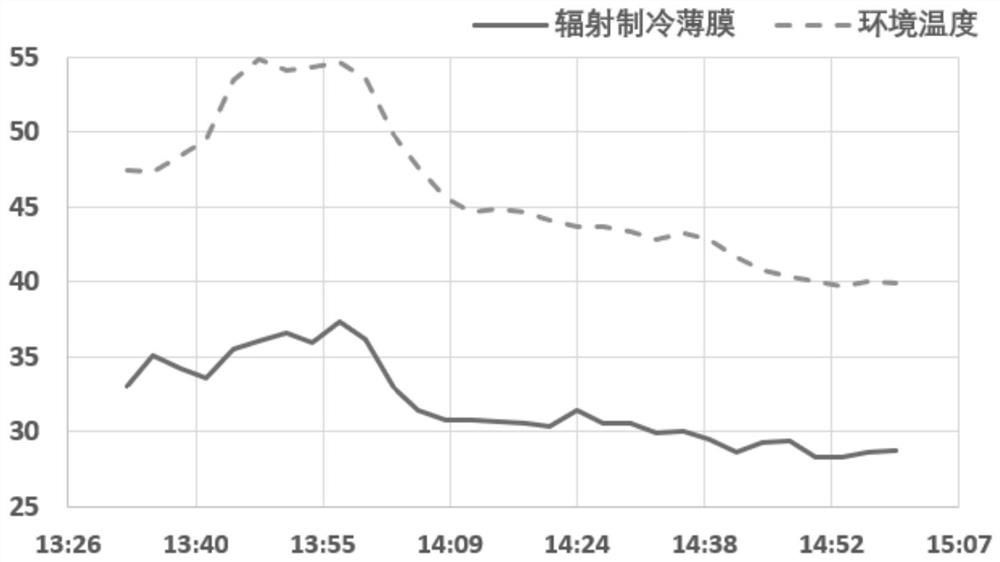

A technology of radiation cooling and radiation cooling, applied in the field of functional thin film materials, can solve the problems of cooling, high cost, complicated preparation process, etc., and achieve the effects of lowering indoor temperature, fast film forming speed, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a porous radiation refrigeration film, comprising the following steps:

[0036] (1) miscible with the first solvent to form a uniform mixed solution with the material having the ability to radiate the atmospheric window corresponding to infrared electromagnetic wave radiation;

[0037] (2) forming the mixed solution on the substrate;

[0038] (3) On the substrate formed with the mixed solution, a second solvent that does not dissolve the material having the ability to radiate the atmospheric window corresponding to infrared electromagnetic waves is formed to obtain a porous radiation cooling film, wherein the second solvent and the first The solvents are miscible.

[0039] In a specific embodiment, step (4) is also included during or after the step (3): subjecting the film to curing or natural air-drying; the curing includes placing the film at 50°C A heating device at -80° C. is used for drying treatment for 1-10 hours; t...

Embodiment 1

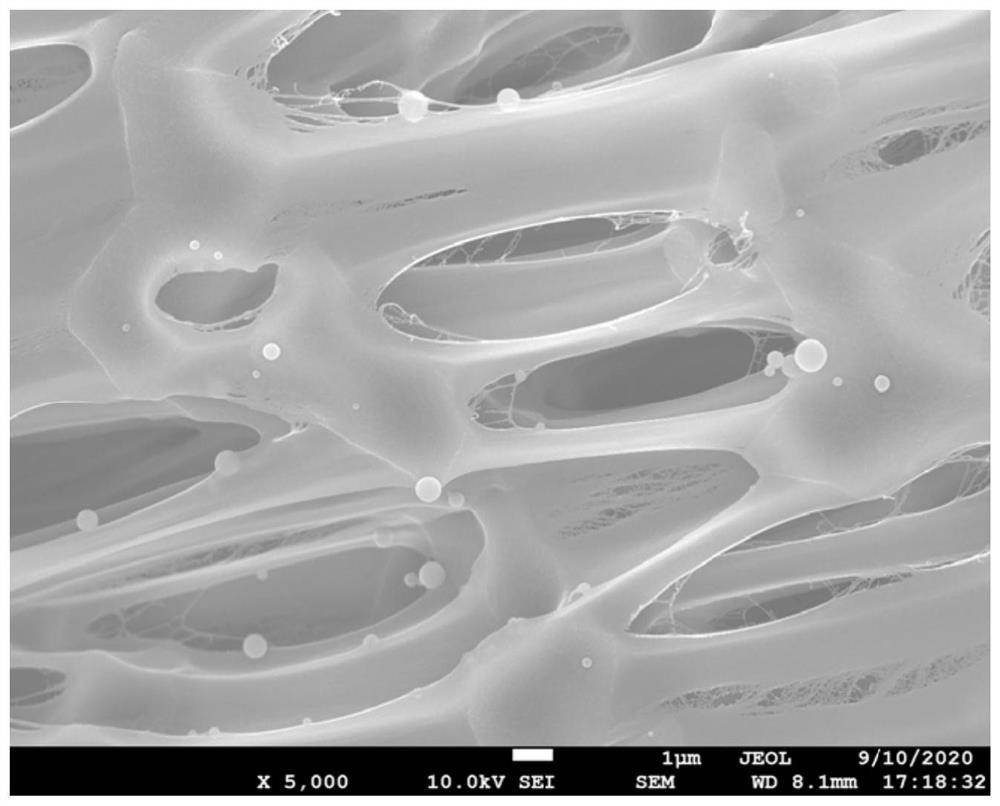

[0051] The preparation of the porous radiative refrigeration film requires the following raw materials: the polymer is polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) (weight percentage) 15wt%, the solvent is N,N-dimethylformamide (DMF) 85wt% , the non-solvent is water.

[0052] The preparation process of the porous radiative cooling film is as follows: fully mix PVDF-HFP and DMF according to the above mass percentage, and let stand for defoaming treatment; after defoaming treatment, spin-coat the mixed solution on a smooth glass substrate, and then quickly coat the The glass substrate of the mixed solution was placed in room temperature water. Take out after the mixed solution forms a film and falls off. Finally, put the taken-out film into an oven at 60°C for two hours of drying treatment to obtain a porous radiative cooling film.

Embodiment 2

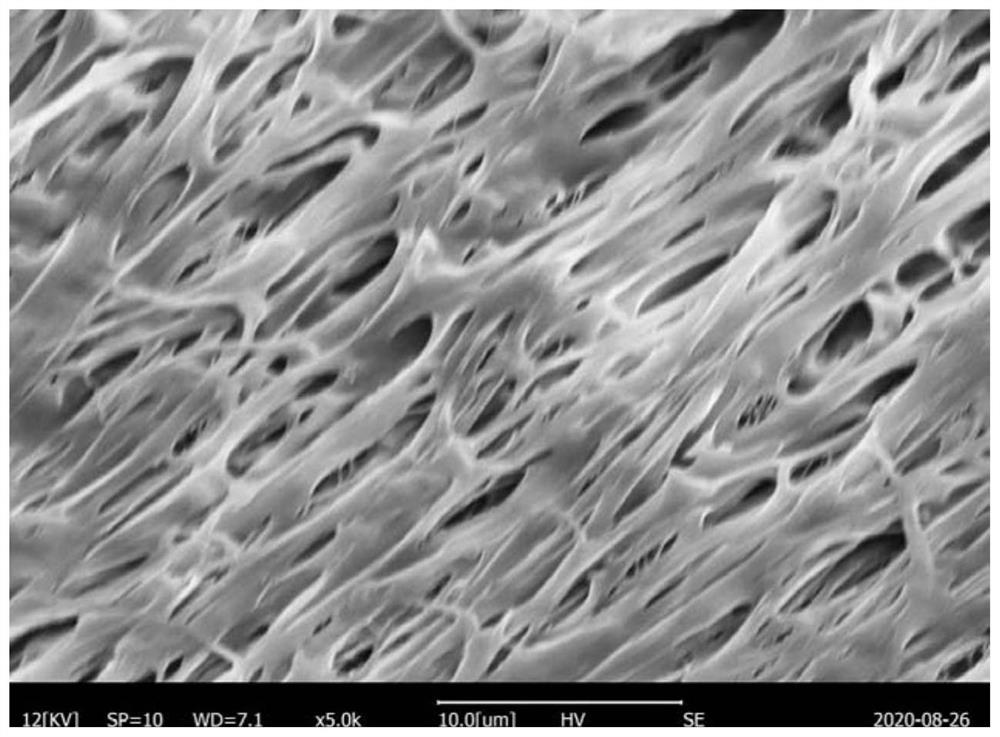

[0054] The preparation of the porous radiative cooling film requires the following raw materials: the polymer is polyvinylidene fluoride (weight percentage) 19 wt%, the solvent is dimethylacetamide (DMAC) 81 wt%, and the non-solvent is alcohol.

[0055] The preparation process of the porous radiative cooling film is as follows: fully mix polyvinylidene fluoride and DMAC according to the above mass percentage, and let it stand for defoaming treatment; after defoaming treatment, apply the mixed solution on a smooth glass substrate, and then quickly apply Put the glass substrate with the mixed solution into the normal temperature alcohol. Take out after the mixed solution forms a film and falls off. Finally, put the taken-out film into an oven at 50° C. for drying for one hour to obtain a porous radiative cooling film. figure 2 It is the SEM image of the porous radiative cooling film prepared by using DMAC as a solvent in the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com