A Coating-Based Pulse Sequence Modulator

A pulse sequence and modulator technology, applied in the field of ultrafast laser pulse sequence modulation method and modulator, can solve the problems of high cost, slow modulation speed, low damage threshold, etc., achieve low cost, improve reliability and stability, The effect of reducing system complexity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

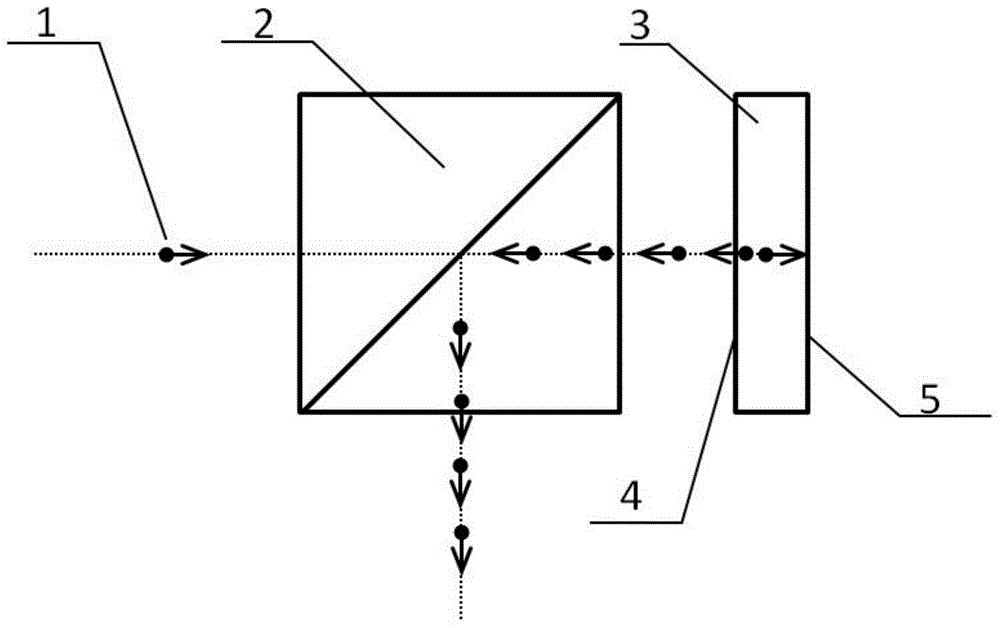

[0028] A coating-based pulse sequence modulator includes: an ultrafast laser pulse 1, a beam splitter 2, a modulation lens 3, a front surface 4, and a rear surface 5.

[0029] The connection relationship is:

[0030] After the ultrafast laser pulse 1 passes through a beam splitter 2 placed at 45 degrees to the laser propagation direction, it is vertically incident on the front surface 4 of the modulation lens 3, then passes through the modulation lens 3 to the rear surface 5, and passes through the modulation lens 3. After modulation, a beam of pulse sequence is reflected back from the front surface 4 and propagates along the direction opposite to the incident laser. This beam of pulse sequence is reflected after encountering the mirror 2 and separated from the incident laser. Direction output, both the front surface 4 and the rear surface 5 of the modulation lens 3 are coated with a semi-transparent and semi-reflective film;

[0031] The base material of the modulated lens 3...

Embodiment 2

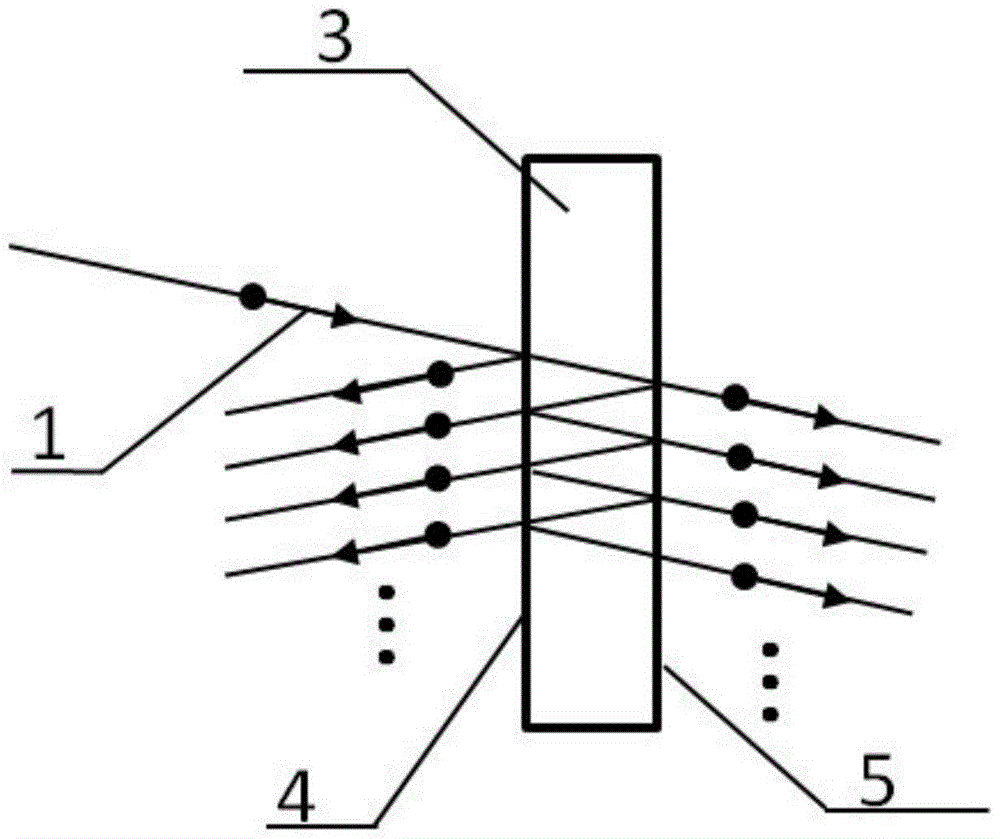

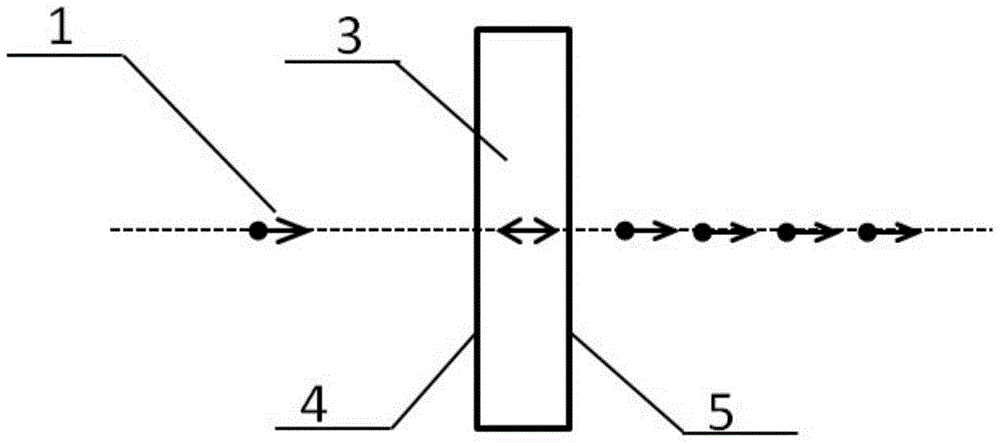

[0038] A pulse sequence modulator based on coating, comprising: 1—ultrafast laser pulse, 3—modulation mirror, 4—front surface, 5—rear surface.

[0039] The connection relationship is:

[0040] The ultrafast laser pulse 1 is vertically incident on the front surface 4 of the modulation lens 3 , and reaches the rear surface 5 after passing through the modulation lens 3 .

[0041] The material of the modulation lens 3 in this embodiment is N-BK7, the thickness is 100um, the front surface 4 is coated with a layer of broadband dielectric film, the reflectivity in the 700-920 wavelength range is 40%, and the rear surface 5 is coated with a layer of A dielectric film with a reflectivity of 50% in the wavelength range of 700-920. When inputting a femtosecond laser with a center wavelength of 800 nm and a pulse width of 50 fs, the delay of adjacent sub-pulses in the pulse train output from the rear surface 5 is 1 ps, and the energy ratio of each sub-pulse is: 100:20:5:1: ....

[0042...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com