Solar cell anti-reflection film and preparation method and application thereof

A technology of solar cells and anti-reflection coatings, applied in the field of solar cells, can solve the problems of high performance requirements of photoresist against strong acid corrosion, difficulty in removing glue, and lower refractive index, so as to facilitate battery performance testing and interconnection Welding, reducing the risk of damage and process difficulty, the effect of low reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

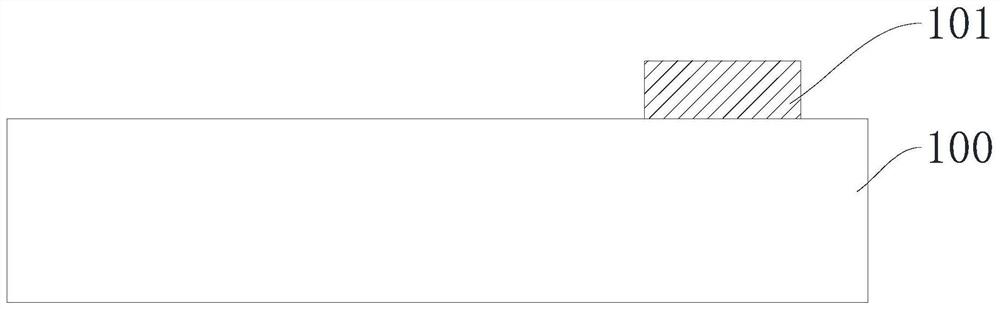

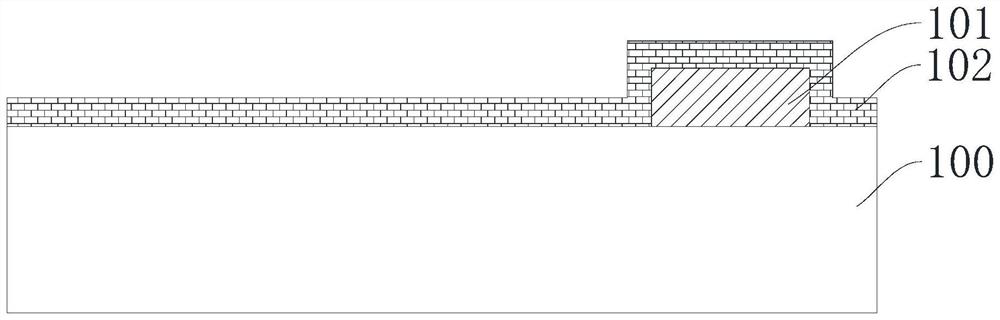

[0081] This embodiment is a solar cell anti-reflection film, which is formed by stacking the following film layers in sequence:

[0082] At a wavelength of 550 nm, the inorganic layer 102 (TiO 2 Floor);

[0083] At a wavelength of 550 nm, a photoresist layer 103 with a refractive index of 1.6 and a thickness of 102 nm (SU8 photoresist (SU8-2000.5 photoresist from Micro Chem, USA) layer).

Embodiment 2

[0085] This embodiment is a solar cell anti-reflection film, which is formed by stacking the following film layers in sequence:

[0086] At a wavelength of 550 nm, the inorganic layer 102 (TiO 2 Floor);

[0087] At a wavelength of 550 nm, a photoresist layer 103 with a refractive index of 1.6 and a thickness of 90 nm (SU8 photoresist (SU8-2000.5 photoresist from Micro Chem, USA) layer).

Embodiment 3

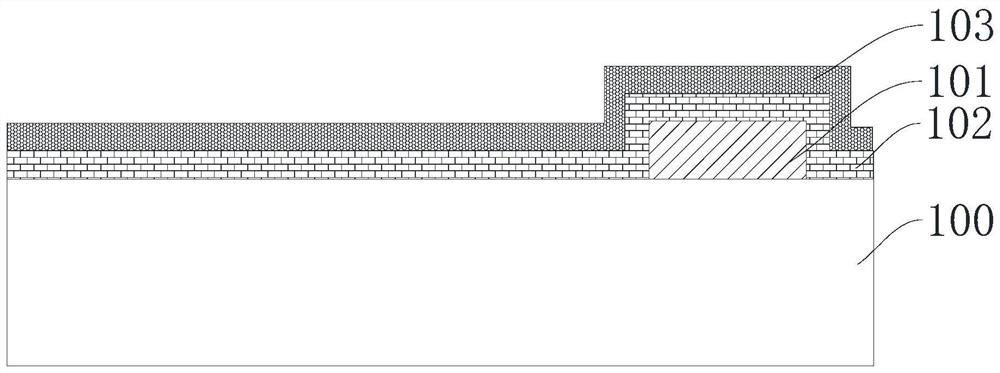

[0089] The present embodiment is the preparation method of the solar cell anti-reflection film in the embodiment 1, which is composed of the following steps:

[0090] S1, using the method of electron beam evaporation (evaporation temperature 220 ℃, evaporation initial vacuum value 8 × 10 -6 Torr, evaporation rate 0.2nm / s), an inorganic layer 102 (TiO2) with a thickness of 68nm was evaporated on the substrate 2 film), when the wavelength is 550nm, its refractive index is 2.35.

[0091] S2. Coat the surface of the inorganic layer 102 with photoresist (SU8 photoresist), and after exposure, bake in an oven at 200° C. for 30 minutes to completely vitrify the SU8 photoresist. The vitrified photoresist has a thickness of 102 nm and a refractive index of 1.6 at a wavelength of 550 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com