Lead-free solder for sealing tempered vacuum glass in atmospheric environment and pressure brazing sealing method thereof

A lead-free solder, atmospheric environment technology, used in welding/cutting media/materials, welding equipment, welding media, etc., can solve problems such as low production efficiency, cumbersome sealing process, troublesome operation, etc. Mechanical properties, the effect of less components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

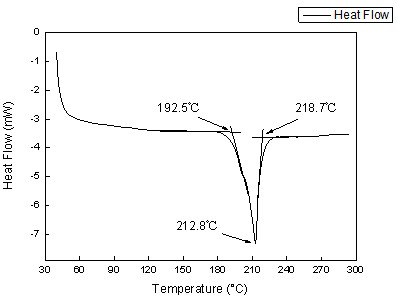

Embodiment 1

[0035] A lead-free solder for sealing tempered vacuum glass in an atmospheric environment and a pressurized brazing sealing method thereof, specifically comprising the following steps:

[0036] (1) Lead-free solder ingredients

[0037] In the lead-free solder, In accounts for 5.0% by weight of the solder, Ag accounts for 1.0% by weight of the solder, Ga accounts for 1.5% by weight of the solder, the rest is Sn, and the unavoidable impurity content is less than 0.2%. The raw materials of the components are all granular, with a purity of 99.99%.

[0038] (2) Preparation of lead-free solder

[0039] According to the weight ratio of Sn:In, Sn:Ag and Sn:Ga 1:1, weigh the raw materials respectively and place them in the crucible of the vacuum induction melting furnace. After vacuuming, fill it with argon for melting. The melting temperature is 500℃~600℃ , the smelting time is 20min~30min, the vacuum degree is 10-4Pa, and the magnetic force is continuously added to stir during the ...

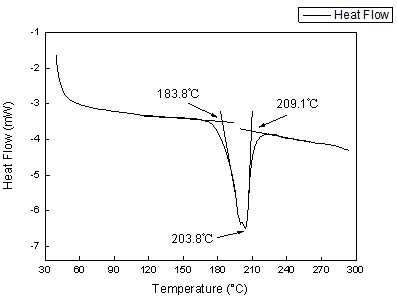

Embodiment 2

[0044] A lead-free solder for sealing tempered vacuum glass in an atmospheric environment and a pressurized brazing sealing method thereof, specifically comprising the following steps:

[0045] (1) Lead-free solder ingredients

[0046] In the lead-free solder, In accounts for 5.0% by weight of the solder, Ag accounts for 4.0% by weight of the solder, Ga accounts for 0.05% by weight of the solder, the rest is Sn, and the unavoidable impurity content is less than 0.2%. The raw materials of the components are all granular, with a purity of 99.99%.

[0047] (2) Preparation of lead-free solder

[0048] According to the weight ratio of Sn:In, Sn:Ag and Sn:Ga 1:1, weigh the raw materials respectively and place them in the crucible of the vacuum induction melting furnace. After vacuuming, fill it with argon for melting. The melting temperature is 500℃~600℃ , the smelting time is 20min~30min, the vacuum degree is 10-4Pa, and the magnetic force is continuously added to stir during the...

Embodiment 3

[0053] A lead-free solder for sealing tempered vacuum glass in an atmospheric environment and a pressurized brazing sealing method thereof, specifically comprising the following steps:

[0054] (1) Lead-free solder ingredients

[0055] In the lead-free solder, In accounts for 5.0% by weight of the solder, Ag accounts for 2.5% by weight of the solder, Ga accounts for 1.0% by weight of the solder, the rest is Sn, and the unavoidable impurity content is less than 0.2%. The raw materials of the components are all granular, with a purity of 99.99%.

[0056] (2) Preparation of lead-free solder

[0057] According to the weight ratio of Sn:In, Sn:Ag and Sn:Ga 1:1, weigh the raw materials respectively and place them in the crucible of the vacuum induction melting furnace. After vacuuming, fill it with argon for melting. The melting temperature is 500℃~600℃ , the smelting time is 20min~30min, the vacuum degree is 10-4Pa, and the magnetic force is continuously added to stir during the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com