Anti-corrosion pipeline production forming method

A forming method and pipeline technology, which is applied in spray booths, pretreatment surfaces, spray devices, etc., can solve problems such as increased employee workload, missed spraying, and scratches on the anti-corrosion layer, so as to avoid uneven spraying thickness and missed spraying , the effect of increasing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

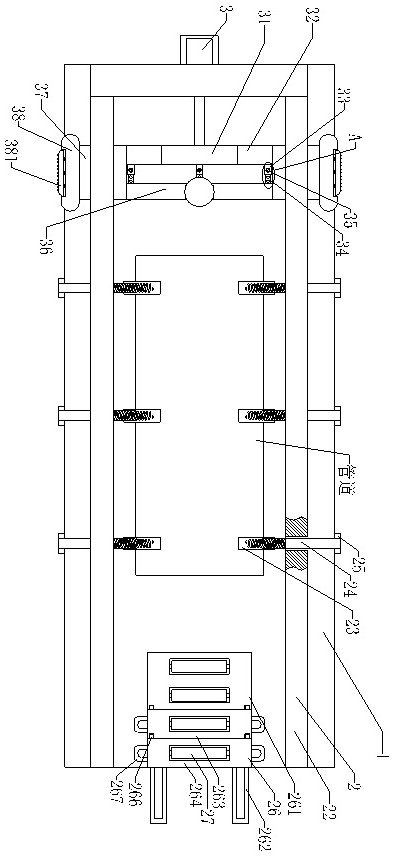

[0033]Such asFigure 1 to Figure 9As shown, an anticorrosive pipeline production molding method mainly includes the following steps:

[0034]Step 1: Equipment inspection: Check the operation of the equipment before using the anticorrosive pipeline surface spraying equipment to spray the pipeline surface with anticorrosive agent;

[0035]Step 2: Pipeline installation: manually place the pipeline that needs anti-corrosion treatment on the feed support plate 26, then manually push the pipeline into the sliding guide 22, and the inner splint 23 clamps the pipeline to achieve the purpose of pipeline installation;

[0036]Step 3: Surface spraying: After completing the pipeline installation, the No. 1 hydraulic cylinder works and drives the connecting block 31 to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com