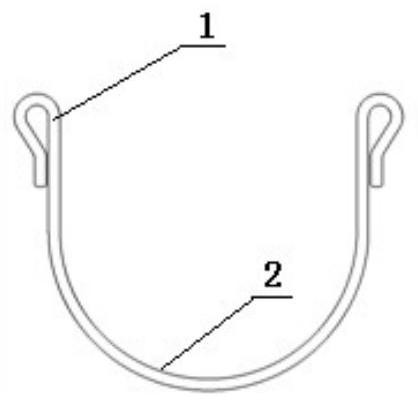

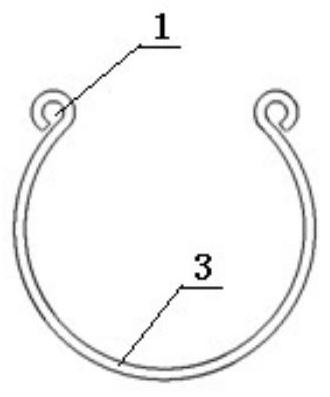

Carbon fiber/carbon composite material C-shaped artificial tracheal stent with high bioactivity and preparation method thereof

A carbon composite material, tracheal stent technology, applied in the direction of stents and other directions, can solve the problems of high surface hardness and low friction coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

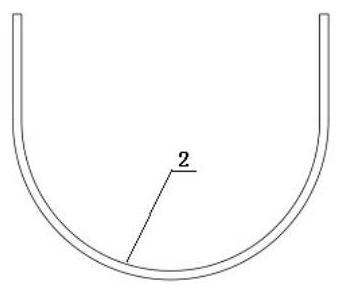

[0062] 1) First twist 2 bundles of 1k into fiber ropes, and then use 16 carbon fiber ropes to weave into a 6mm wide carbon fiber pipe belt with a pipe braiding machine, and the pipe wall thickness is 0.2mm;

[0063] 2) Fill the inner cavity of the carbon fiber tube and belt structure with polyethylene particles, reserve a fixed hole with a diameter of 1.0 mm by means of a mold, and carry out warm pressing molding. , made into a hollow ribbon structure, that is, a C-shaped artificial trachea stent blank;

[0064] 3) After cooling down, remove the mold, heat up to 80°C again, and take out the softened polyethylene material in the inner cavity of the C-shaped artificial tracheal stent blank;

[0065] 4) Dense carbon matrix of the shaped C-shaped artificial trachea stent blank, and the densified carbon matrix adopts a chemical vapor deposition process. The flow ratio of methane and hydrogen is 1:0.5, and the deposition is 80h;

[0066] 5) Processing such as cutting ends;

[006...

Embodiment 2

[0073] 1) First, 24 bundles of 3k carbon fiber bundles are woven into 8mm wide carbon fiber tube belts with a tube braiding machine, and the tube wall thickness is 0.3mm;

[0074] 2) Fill the inner cavity of the carbon fiber tube-belt structure with polystyrene particles, reserve a fixed hole with a diameter of 0.5 mm by means of a mold, and carry out warm-press molding, the conditions of the warm-press molding are: the temperature is 230 ° C, the time For 5h, a hollow ribbon structure is made, that is, a C-shaped artificial trachea stent blank;

[0075] 3) After cooling down, remove the mold, heat up to 100°C again, and take out the softened polystyrene material in the inner cavity of the C-shaped artificial tracheal stent blank;

[0076] 4) Dense carbon matrix of the shaped C-shaped artificial trachea stent blank, and the densified carbon matrix adopts a chemical vapor deposition process, and the specific process is: put the carbon fiber preform into a deposition furnace, an...

Embodiment 3

[0085] 1) First twist 2 bundles of 6k carbon fiber bundles into fiber ropes, and then use 12 carbon fiber ropes to weave into 4mm wide carbon fiber pipe belts with a tubular braiding machine;

[0086] 2) Fill the inner cavity of the carbon fiber tube-belt structure with polystyrene particles, and perform warm-press molding with the aid of a mold. The conditions of the warm-press molding are as follows: the temperature is 230° C. and the time is 5 hours to form a hollow-core ribbon structure, That is, the C-shaped artificial trachea stent blank;

[0087] 3) After cooling down, remove the mold, heat up to 100°C again, and take out the softened polystyrene material in the inner cavity of the C-shaped artificial tracheal stent blank;

[0088] 4) Dense carbon matrix of the shaped C-shaped artificial trachea stent blank, and the densified carbon matrix adopts a chemical vapor deposition process, and the specific process is: put the carbon fiber preform into a deposition furnace, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com