Efficient double-face polishing equipment for multi-model nodular cast iron well lids

A ductile iron, multi-model technology, used in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of high labor intensity, limited use range, low grinding precision, etc., to improve practicability, improve The effect of working efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

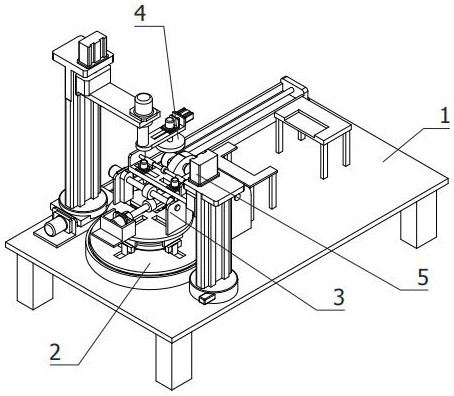

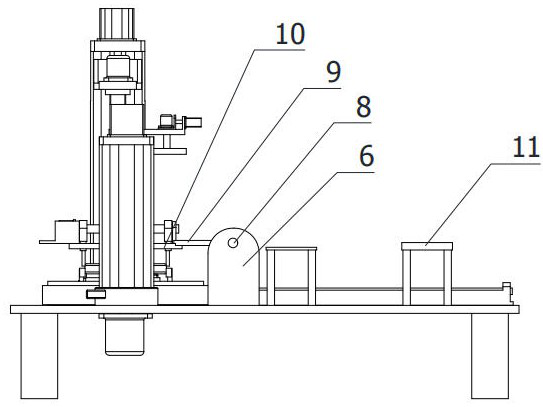

[0075] refer to Figure 1-Figure 4 A high-efficiency double-sided grinding equipment for multi-model ductile iron manhole covers is shown, including:

[0076] Rack 1;

[0077] The positioning and clamping assembly 2 is arranged on the frame 1 and is used for positioning and clamping the ductile iron manhole cover;

[0078] The overturn clamping assembly 3 is arranged on the frame 1, and is used for clamping the upper half of the ductile iron manhole cover after the upper surface of the manhole cover is polished, and carries it to overturn, so as to polish the reverse side of the nodular cast iron manhole cover;

[0079] The surface grinding assembly 4 is arranged on the frame 1 and is located beside the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com