Assembly type composite wall structure and assembly method thereof

A composite wall and prefabricated technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of poor earthquake resistance, easy deformation, falling off, etc., and achieve simple on-site construction, high stability of the overall structure, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

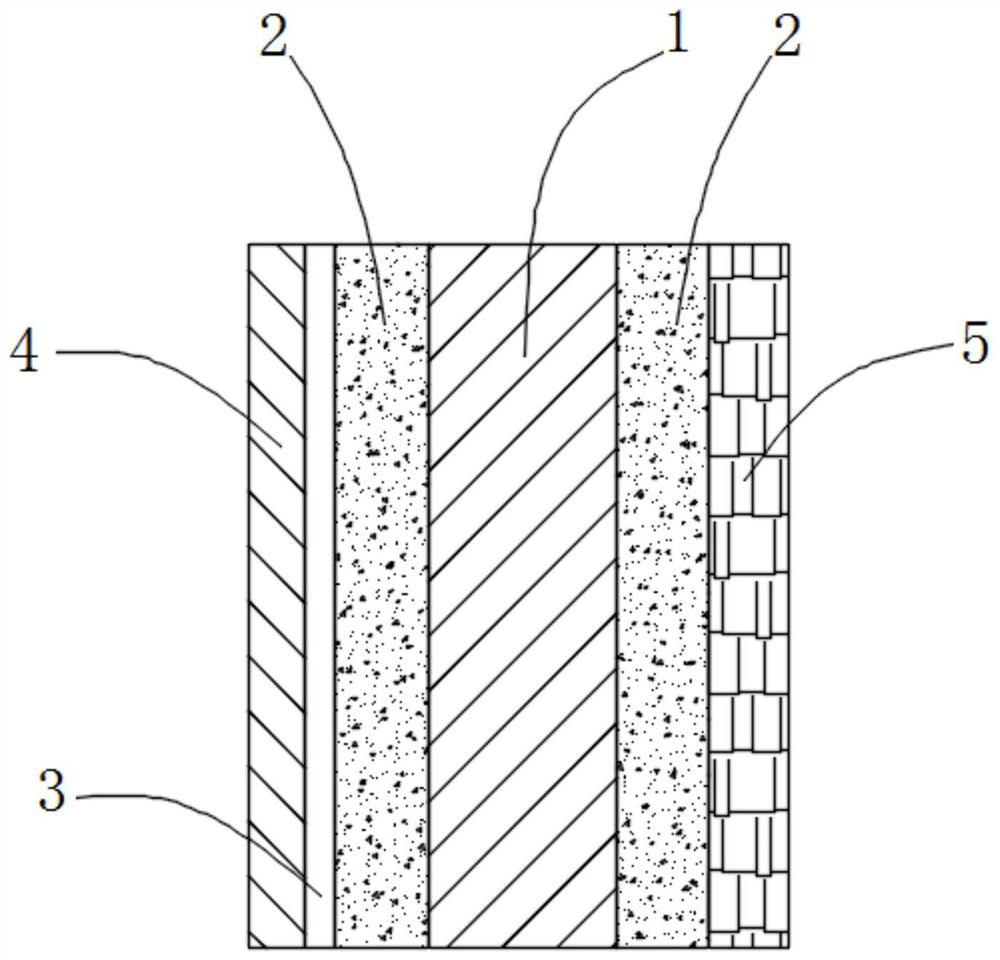

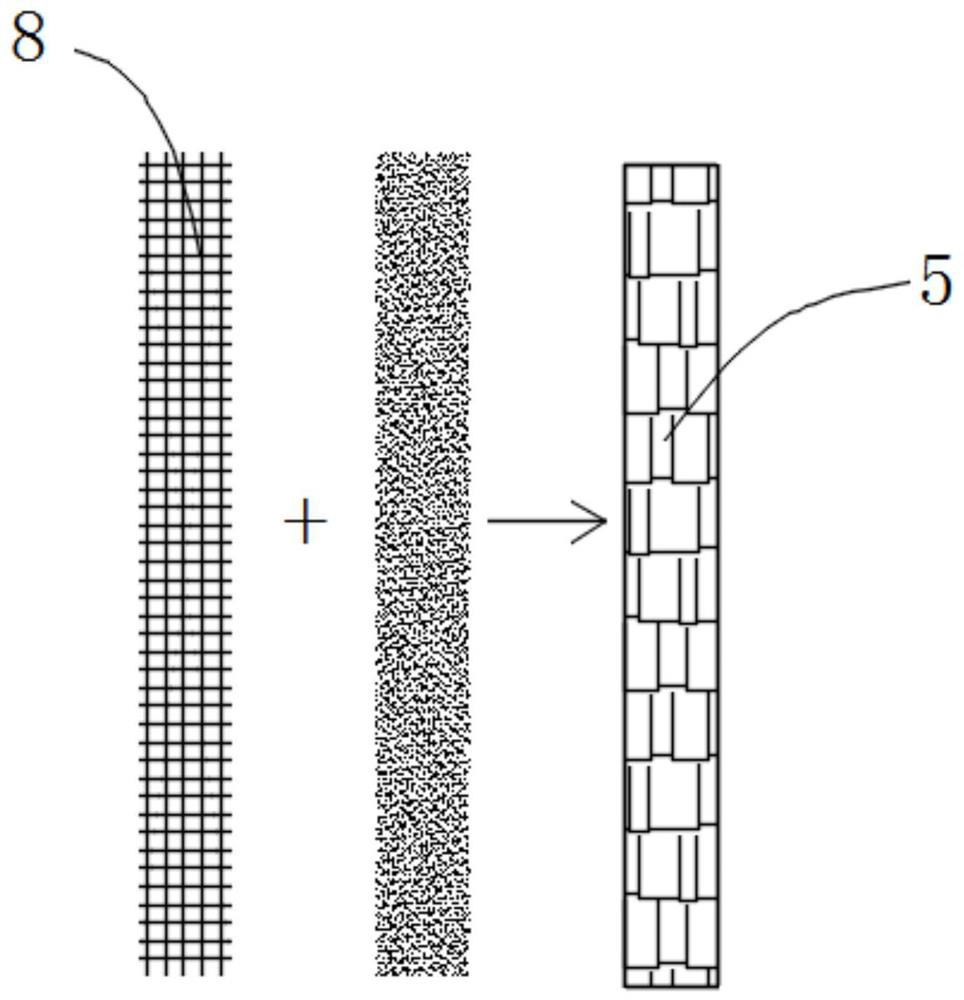

[0033] Such as Figure 1~3 As shown, the present embodiment provides a structural schematic diagram of a prefabricated composite wall structure, including a main beam 1, an insulation layer 2 is provided on both sides of the main beam 1, and the insulation layer 2 is made of mortar queen masterbatch and base material according to the quality The ratio is 5:100, and the base material is composed by weight: 20 parts of fly ash, 50 parts of stone powder, 15 parts of talcum powder, 3 parts of calcium powder, 10 parts of laterite powder, and 5 parts of fine sand. The thermal insulation layer of this embodiment can not only increase the thermal insulation performance of the whole wall, but also increase the structural strength of the thermal insulation layer. However, the existing wall structure only has one layer of insulation layer, and the material of the insulation layer generally adopts insulation material boards, such as perlite insulation boards and polyurethane insulation bo...

Embodiment 2

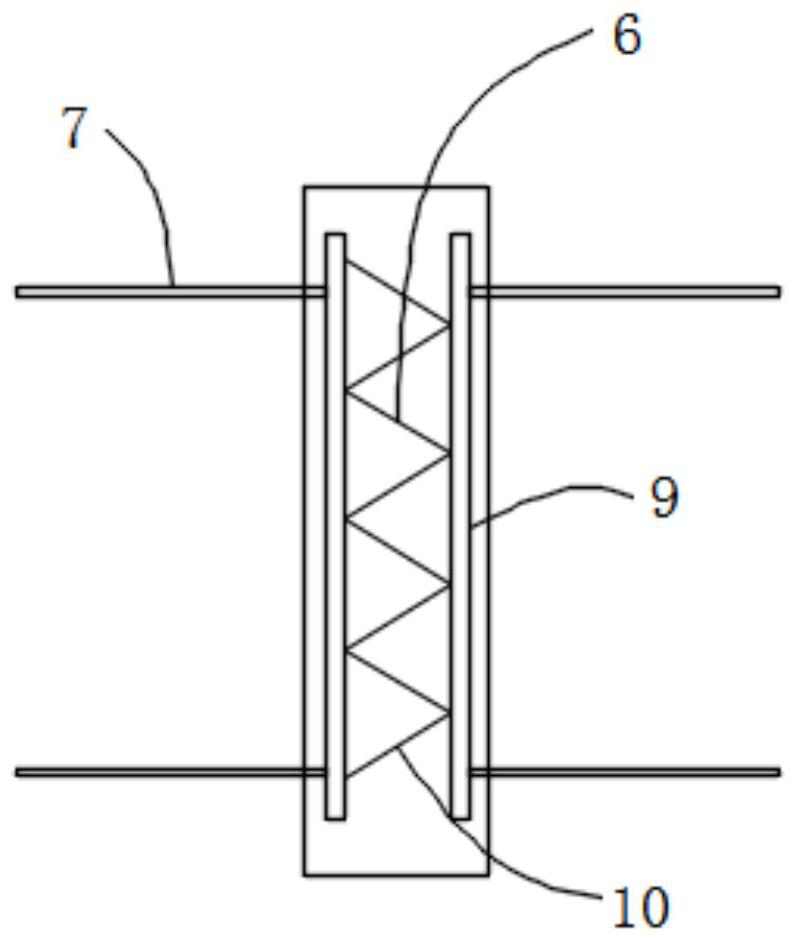

[0038] Such as Figure 1-5As shown, this embodiment provides a prefabricated composite wall structure, and the difference from Embodiment 1 is that: the main beam 1 is also provided with embedded parts 11, and the embedded parts 11 include two vertical main steel bars 9 respectively. The welded steel bar cover 12, the steel bar cover 12 is sleeved with a balance bar 13, and the two ends of the balance bar 13 are fixedly connected to the positioning block 14. In the present embodiment, the balance bar 13 and the positioning block 14 are an integral structure, and the positioning block 14 The quantity is 8, and 8 positioning blocks 14 are respectively 4 / 4 fixed on the upper and lower sides end faces close to the main beam 1, and the fixing blocks are iron blocks or steel blocks. In other embodiments, the balance rib and the positioning block may also be connected by hinges, welding and the like. Regardless of whether the seismic energy is transmitted from the left and right sid...

Embodiment 3

[0040] This embodiment provides an assembled composite wall structure. The difference from Embodiment 2 is that the insulation layer is prepared by mixing the mortar queen mother material and the base material at a mass ratio of 2:100, wherein the base material is prepared in parts by weight The composition includes: 35 parts of fly ash, 100 parts of stone powder, 8 parts of talc powder, 1 part of calcium powder, 6 parts of laterite powder, 15 parts of fine sand, 5 parts of expanded perlite, and 3 parts of silanized polypropylene fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com