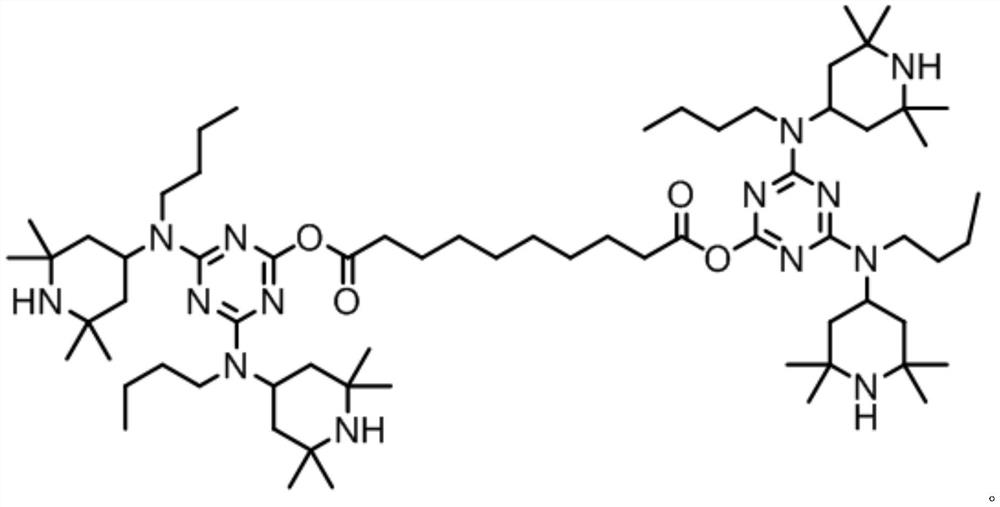

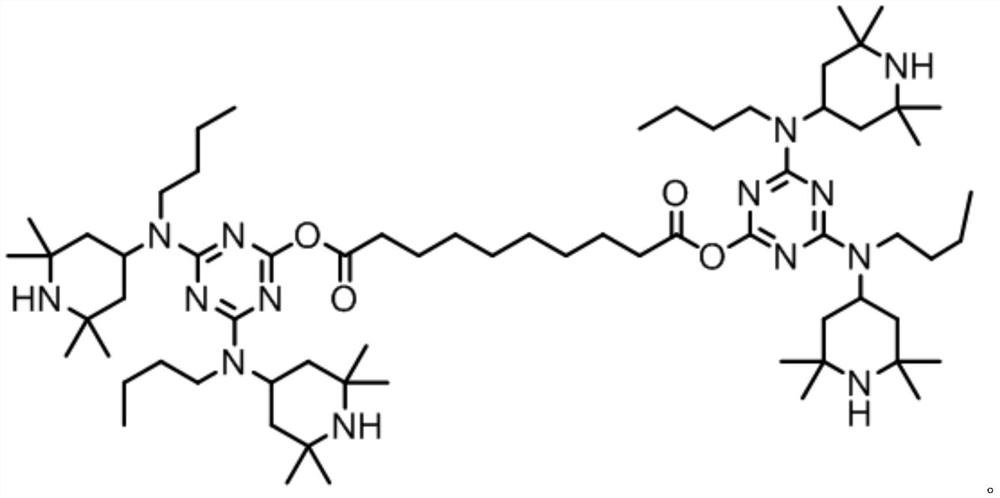

Hindered amine light stabilizer and preparation process thereof

A light stabilizer and hindered amine technology, which is applied in the field of hindered amine light stabilizers and their preparation technology, can solve the problems of poor performance and low proportion of hindered amine groups, and achieve low price, mild reaction conditions, and easy preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

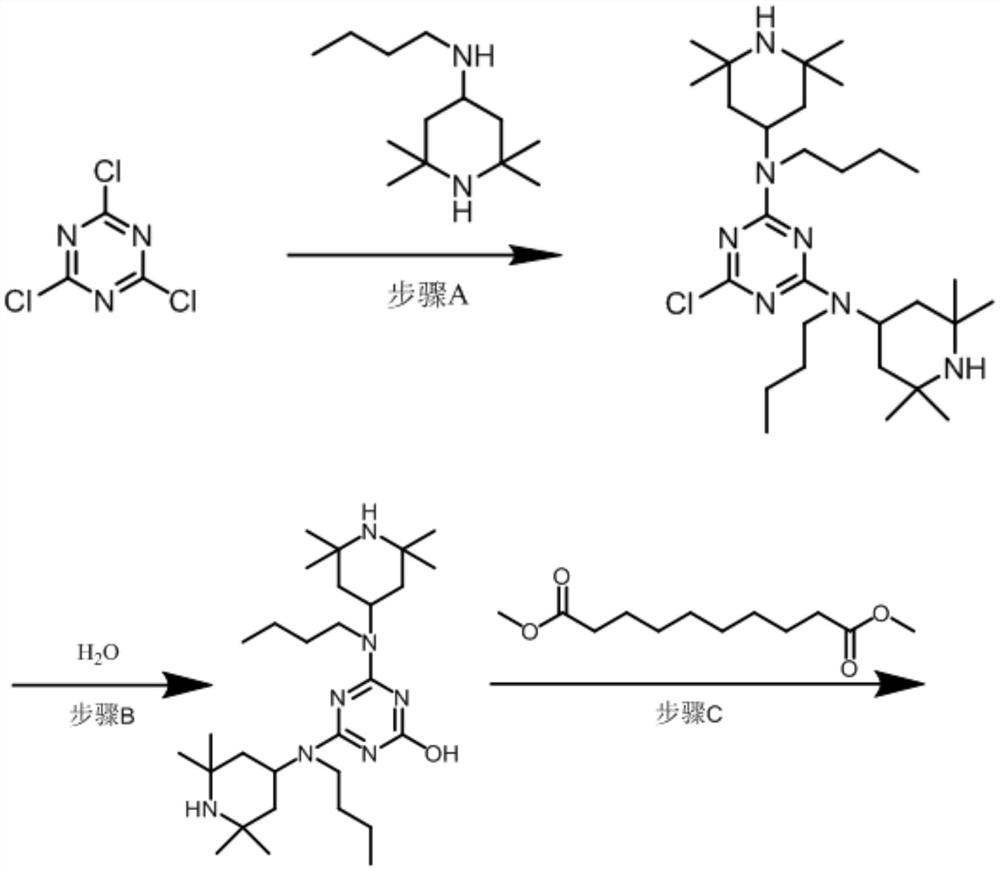

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of light stabilizer, comprising the following steps:

[0030] Add 500g of xylene solvent into a 3L high-pressure reactor, add 92g of cyanuric chloride at room temperature, control the temperature below 50°C and add 205g of N-butyl-2,2,6,6-tetramethyl dropwise under stirring -4-Piperidinamine, the dropwise addition was completed in about 20 minutes. After the dropping, the temperature was controlled at 55°C for 2 hours. The liquid phase detection raw material cyanuric chloride was completely reacted, and then 110g of sodium hydroxide solution with a mass fraction of 40% was added dropwise. , the temperature was raised to 60° C. for 5 hours, and after the reaction was complete, 200 g of water was added to wash with water, and the water was separated after washing with water for 3 times. Add 60g of 40% sodium hydroxide solution and 10g of PEG-400 to the system, close the autoclave, react at 160°C for 10h, and then cool down to 90°C;

[0031] The salt ...

Embodiment 2

[0033] A preparation method of light stabilizer, comprising the following steps:

[0034] Add 500g of xylene solvent into a 3L high-pressure reactor, add 92g of cyanuric chloride at room temperature, control the temperature below 50°C and add 220g of N-butyl-2,2,6,6-tetramethyl dropwise under stirring -4-Piperidinamine, the dropwise addition is completed in about 20 minutes, after the dropwise reaction, the temperature is controlled at 50°C for 2 hours, the liquid phase detection raw material cyanuric chloride has completely reacted, and then 110g of sodium hydroxide solution with a mass fraction of 40% is added dropwise , the temperature was raised to 60° C. for 5 hours, and after the reaction was complete, 200 g of water was added to wash with water, and the water was separated after washing with water for 3 times. Add 60g of 40% sodium hydroxide solution and 10g of PEG-400 into the system, close the autoclave, react at 160°C for 12h, and then cool down to 90°C;

[0035] Th...

Embodiment 3

[0037] A preparation method of light stabilizer, comprising the following steps:

[0038] Add 1000g of xylene solvent into a 3L autoclave, add 184g of cyanuric chloride at room temperature, control the temperature below 50°C and add 460g of N-butyl-2,2,6,6-tetramethyl dropwise under stirring -4-Piperidinamine, the dropwise addition is completed in about 20 minutes, after the dropping, the temperature is controlled at 50°C for 2 hours, the liquid phase detection raw material cyanuric chloride has completely reacted, and then 200g of sodium hydroxide solution with a mass fraction of 40% is added dropwise , the temperature was raised to 60° C. for 5 hours, and after the reaction was complete, 200 g of water was added to wash with water, and the water was separated after washing with water for 3 times. Add 100g of sodium hydroxide solution with a mass fraction of 40% and 20g of PEG-400 to the system, close the autoclave, react at 160°C for 12h, and then cool down to 90°C;

[0039...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com