Hydrophobic hard coating suitable for high-frequency electrotome and preparation method of hydrophobic hard coating

A technology of high-frequency electric knife and hard coating, which is applied in the direction of coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of passivation, wear resistance and poor thermal conductivity, and avoid passivation The effect of electric knife, improving coating performance and avoiding tissue carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

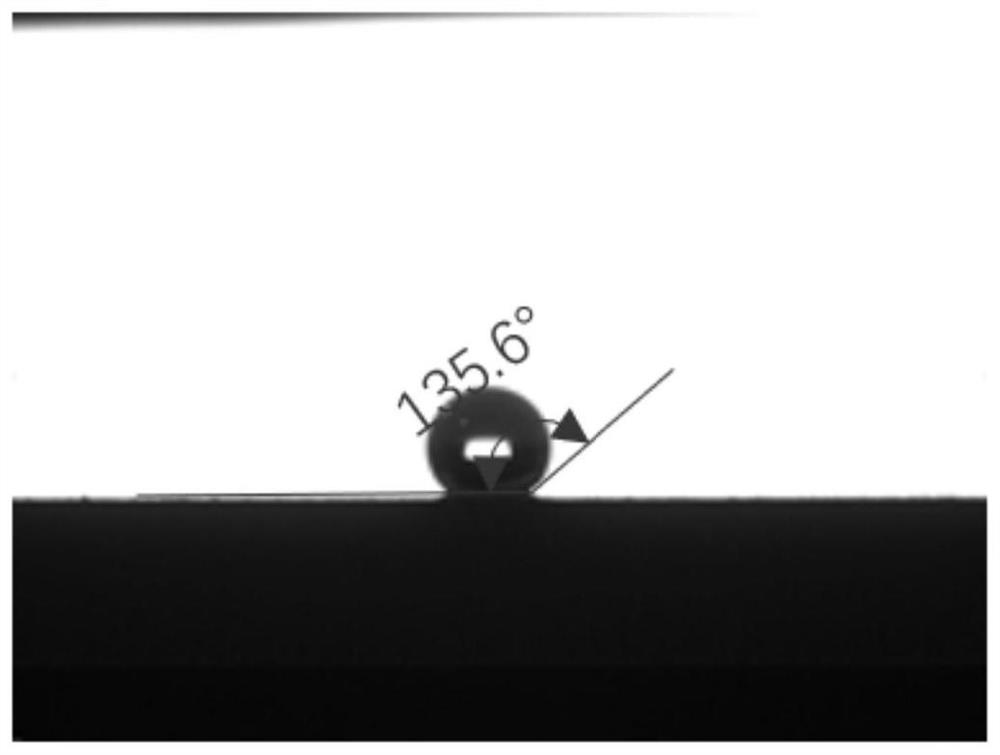

Image

Examples

Embodiment 1

[0033] The high-frequency electric knife is used as the base material, and the material is 304 stainless steel. The specific implementation steps are as follows:

[0034] 1) Clean the stainless steel surface with acetone, alcohol and deionized water in turn, and dry it with a hair dryer;

[0035] 2) The coating is deposited by multi-arc ion plating and magnetron sputtering composite equipment. The targets used are 99.99% pure Cr target, 99.99% pure PTFE target and TiAl target. The molar ratio of Ti and Al in the TiAl target The ratio is 67:33, and the gases used are argon and nitrogen with a purity of 99.99%;

[0036] 3) The Cr layer was deposited by multi-arc ion plating, the working pressure was 0.4Pa, the substrate bias was -450V, the substrate temperature was room temperature, the Cr target sputtering time was 10min, and the atmosphere in the sputtering chamber was argon;

[0037] 4) The CrTiAlN-PTFE layer was deposited by multi-arc ion plating and magnetron sputtering co...

Embodiment 2

[0043] The high-frequency electric knife is used as the base material, and the material is titanium alloy. The specific implementation steps are as follows:

[0044] 1) Clean the surface of the titanium alloy with acetone, alcohol and deionized water in sequence, and dry it with a hair dryer;

[0045] 2) The coating is deposited by multi-arc ion plating and magnetron sputtering composite equipment. The targets used are 99.99% pure Cr target, 99.99% pure PTFE target and TiAl target. The molar ratio of Ti and Al in the TiAl target The ratio is 67:33, and the gases used are argon and nitrogen with a purity of 99.99%;

[0046] 3) The Cr layer is deposited by multi-arc ion plating, the working pressure is 0.2Pa, the substrate bias is -400V, the substrate temperature is room temperature, the Cr target sputtering time is 5min, and the atmosphere in the sputtering chamber is argon;

[0047] 4) The CrTiAlN-PTFE layer was deposited by multi-arc ion plating and magnetron sputtering comp...

Embodiment 3

[0050] The high-frequency electric knife is used as the base material, and the material is tungsten alloy. The specific implementation steps are as follows:

[0051] 1) Clean the surface of the tungsten alloy with acetone, alcohol and deionized water in sequence, and dry it with a hair dryer;

[0052] 2) The coating is deposited by multi-arc ion plating and magnetron sputtering composite equipment. The targets used are 99.99% pure Cr target, 99.99% pure PTFE target and TiAl target. The molar ratio of Ti and Al in the TiAl target The ratio is 67:33, and the gases used are argon and nitrogen with a purity of 99.99%;

[0053] 3) The Cr layer is deposited by multi-arc ion plating, the working pressure is 0.5Pa, the substrate bias voltage is -350V, the substrate temperature is room temperature, the Cr target sputtering time is 15min, and the atmosphere in the sputtering chamber is argon;

[0054] 4) The CrTiAlN-PTFE layer was deposited by multi-arc ion plating and magnetron sputte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com