Method for preparing antioxidant coating on surface of molybdenum and molybdenum alloy protection tube

A technology of anti-oxidation coating and protection tube, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of single composition, short service life, easy cracking of coating, etc., to improve deposition efficiency , optimize the structure, improve the effect of antioxidant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Production of anti-oxidation molybdenum protective tubes for thermocouples of φ8×1×500mm

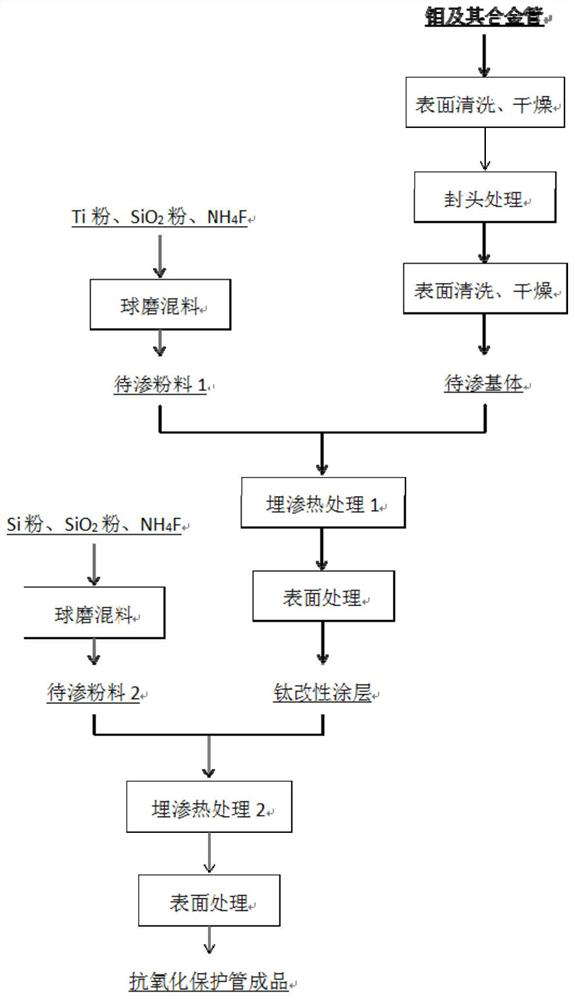

[0041] see figure 1 :

[0042] 1. Place the inner and outer surfaces of the molybdenum tube in a 5wt% NaOH solution, and ultrasonically clean it at room temperature for 20 minutes to remove surface oxides; then use alcohol and distilled water to ultrasonically clean the tube, and dry it in an oven at 80°C.

[0043] 2. Place a φ6×4mm molybdenum block at one end of the molybdenum tube, and use argon arc welding to weld the head. The welding current is 100A, and the argon gas flow rate is 15ml / min. After welding, the molybdenum tube with blind end is cleaned by repeating the method of step 1, dried for later use, and the oxide on the surface of the welded joint is cleaned to obtain the substrate to be infiltrated.

[0044] 3. Ti powder (weight), SiO 2 Powder (weight), NH 4 F (volume) is formulated according to 40:50:10, Ti powder needs 160.8g, SiO 2 Powder needs 201g,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com