Water-resistant and high-temperature-resistant hybrid acrylate-based flexible UV-curable adhesive and preparation method thereof

An acrylate and acrylate technology, used in polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve problems such as over 120 °C, and even occasionally exceed 140 °C, and achieve excellent flexibility. and strength, the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

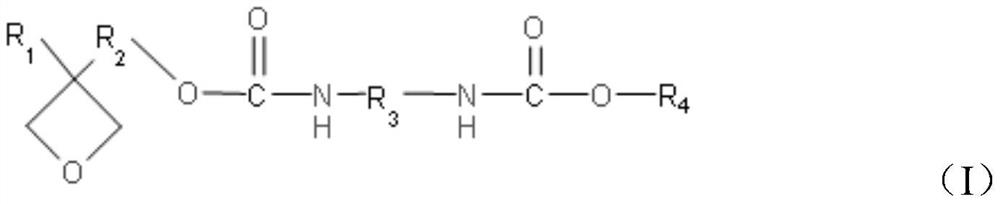

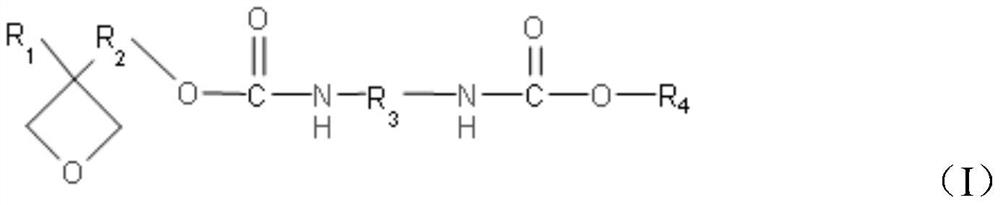

Image

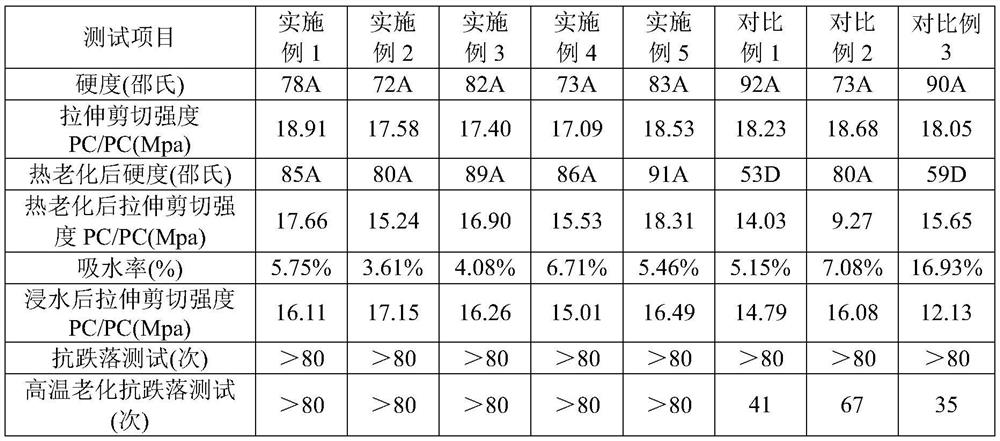

Examples

preparation example Construction

[0034] A method for preparing a water- and high-temperature-resistant mixed-type acrylate flexible UV-curable adhesive, comprising the following steps:

[0035] Step 1. Weighing 5%-10% low Tg reactive diluent, 15%-30% higher Tg flexible acrylic monomer or hybrid acrylic monomer and 2%-5% elastomeric acrylic block copolymer particles;

[0036] Step 2. Add the ingredients in step 1 into the blender, set the stirring speed at 600-800 rpm, control the temperature at 60-80°C, and stir for 2-3 hours to obtain a mixed liquid;

[0037] Step 3. After the mixed liquid obtained in step 2 is clarified and homogenized, the temperature is lowered to 30-40° C., and the mixer is replaced with nitrogen, and the subsequent steps are filled with nitrogen;

[0038] Step 4, then weigh 10% to 20% of self-made cationic radical mixed light-cured acrylate resin, weigh 2% to 10% of novolac epoxy acrylate oligomer, 30% to 50% of polyester Urethane acrylate or polyether polyurethane acrylate flexible ol...

Embodiment 1

[0044] Weigh raw materials according to the following parts by weight: based on 100 parts of the total raw materials, take 20 parts of acryloylmorpholine (ACMO), 8 parts of tetrahydrofuran acrylate (THFA), and 3 parts of Kurarity LA2330 copolymer, add them to the mixer, set stirring The rotation speed is 800 rpm, the temperature is controlled at 70°C, and the stirring time is 3 hours. After the mixed liquid is clarified and uniform, the temperature is lowered to 35°C, and the stirring tank is replaced with nitrogen. The subsequent steps are full of nitrogen, and the self-made cationic radicals are mixed. 15 parts of light-curing acrylic resin No. 1, 5 parts of Shin-A SEA236M50 novolac epoxy acrylate oligomer, 40 parts of Sartomer CN8888NS polyurethane acrylate oligomer, silane coupling agent 3-glycidyl ether oxypropyl Add 2.5 parts of radical trimethoxysilane into the mixer, set the stirring speed at 800 rpm, control the temperature at 35°C, and stir for 1 hour. Take 1841.5 par...

Embodiment 2

[0046] The raw materials were weighed according to the following parts by weight: based on 100 parts of the total raw materials, 22 parts of 2-vinyloxyethoxy ethyl acrylate (VEEA), 6 parts of tetrahydrofuran acrylate (THFA), 3 parts of Kurarity LA2250 copolymer, Add it into the mixer, set the stirring speed to 700 rpm, control the temperature at 80°C, and stir for 2.5 hours. After the mixed liquid is clear and uniform, cool down to 30°C, and replace the stirring tank with nitrogen. Take 12 parts of self-made cationic free radical mixed light-cured acrylic resin No. 1, take 7 parts of Shin-A SEA236M50 novolac epoxy acrylate oligomer, and 41 parts of Nippon Kayaku UFA-2301 polyether polyurethane acrylate oligomer , 2 parts of silane coupling agent 3-glycidyl etheroxypropyl trimethoxysilane, put into the mixer, set the stirring speed at 900 rpm, control the temperature at 30°C, stir for 1 hour, take free radical light 1.5 parts of initiator Omnirad 184, 1 part of free radical pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com