High-temperature low-friction hard nano multi-layer VAlCN/VN-Ag coating as well as preparation method and application thereof

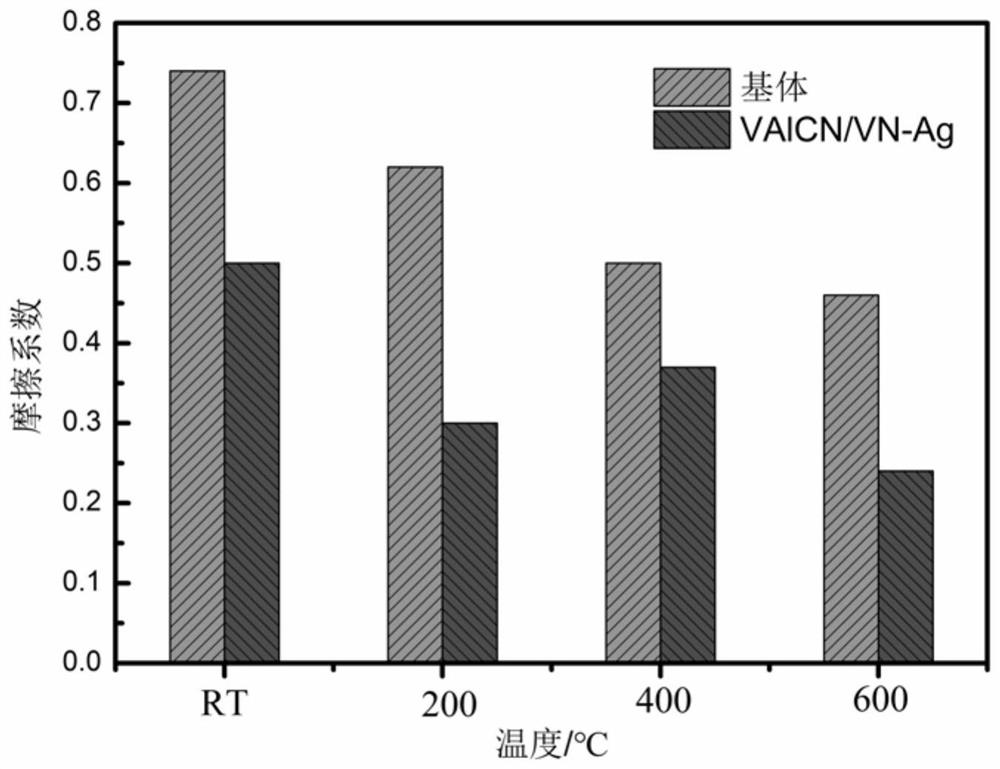

A nano-multi-layer, low-friction technology, applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problem of poor compactness, uniformity and roughness, insufficient high temperature wear resistance and oxidation resistance, Lose the effective anti-friction effect and other problems, to achieve the effect of slowing down the diffusion loss, good application prospects, and meeting the requirements of anti-friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

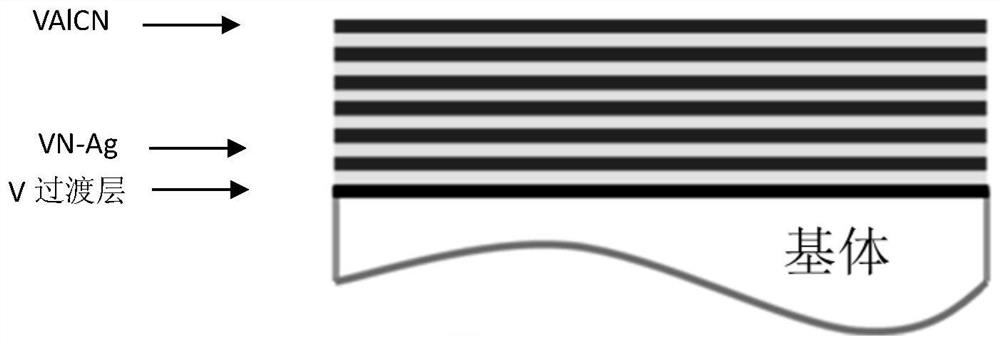

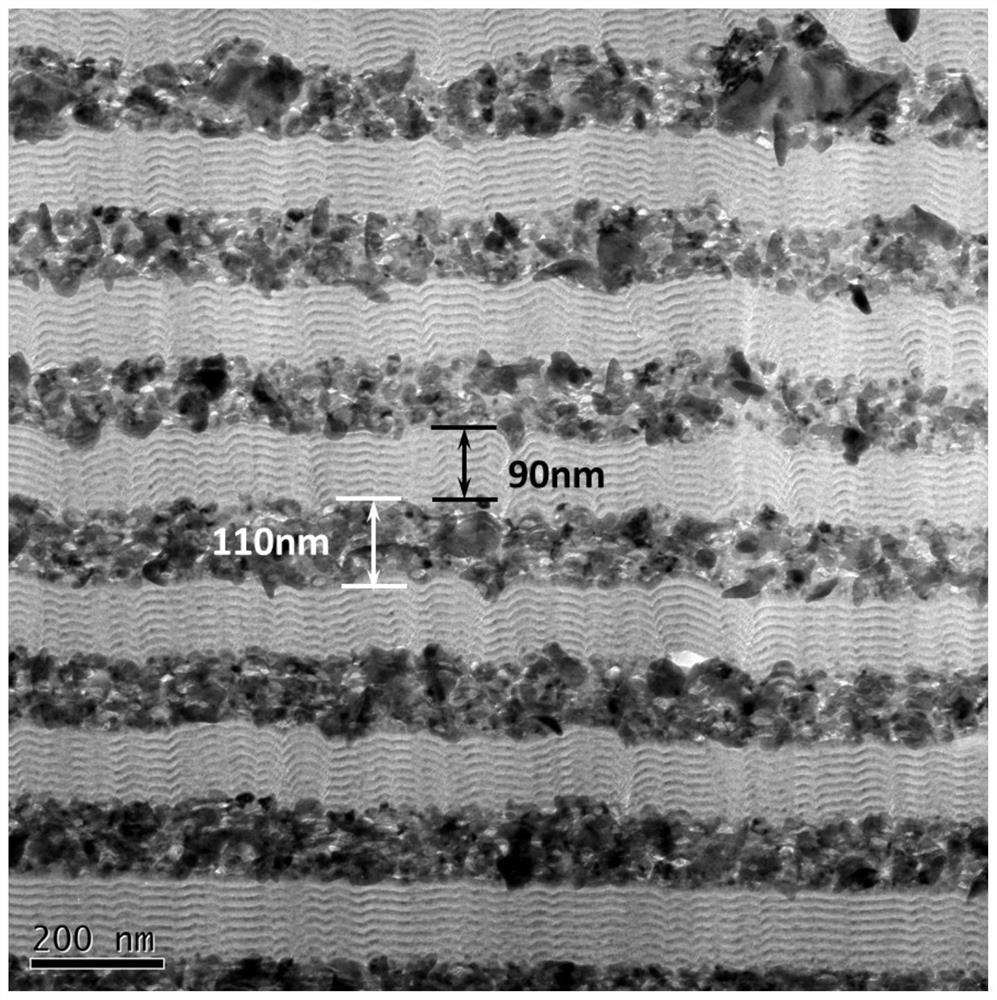

[0046] In this embodiment, the nano-multilayer structure VAlCN / VN-Ag hard coating is composed of alternately stacked VN-Ag layers and VAlCN layers, with a thickness of 3.2 μm. Among them, the thickness of the VAlCN layer is 0.09 μm, the thickness of the VN-Ag layer is 0.11 μm, and the number of alternations is 16 times. The preparation method of this coating comprises the steps:

[0047] (1) Place the nickel-based superalloy substrate in a multi-arc ion plating vapor deposition system, then raise the temperature of the sample stage to 400°C, and guide the argon plasma to bombard and activate the surface of the substrate by applying a negative bias voltage, in which the argon gas The gas flow rate is 150 sccm, the bias voltage is -900V, and the processing time is 10 min.

[0048] (2) Multi-arc ion plating deposits nano-layer structure VAlCN / VN-Ag hard coating: V target, Ag target and Al target are selected as cathodes, and VAlCN / VN is deposited on the substrate by multi-arc io...

Embodiment 2

[0052] The nano-multilayer structure VAlCN / VN-Ag hard coating of this embodiment is composed of alternately stacked VAlCN layers and VN-Ag layers, with a thickness of 8.4 μm. Among them, the thickness of the VAlCN layer is 0.15 μm, the thickness of the VN-Ag layer is 0.2 μm, and the number of alternations is 24 times. The preparation method of this coating comprises the steps:

[0053] (1) Place the nickel-based superalloy substrate in a multi-arc ion plating vapor deposition system, then raise the temperature of the sample stage to 400°C, and guide the argon plasma to bombard and activate the surface of the substrate by applying a negative bias voltage, in which the argon gas The gas flow rate is 150 sccm, the bias voltage is -900V, and the processing time is 10 min.

[0054] (2) Multi-arc ion plating deposits nano-layer structure VAlCN / VN-Ag hard coating: V target, Ag target and Al target are selected as cathodes, and VAlCN / VN is deposited on the substrate by multi-arc ion ...

Embodiment 3

[0057] In this embodiment, the nano-multilayer structure VAlCN / VN-Ag hard coating is composed of alternating layers of VAlCN layers and VN-Ag layers, and the thickness is 12 μm. Among them, the thickness of the VAlCN layer is 0.25 μm, the thickness of the VN-Ag layer is 0.35 μm, and the number of alternations is 20 times. The preparation method of this coating comprises the steps:

[0058] (1) Place the nickel-based superalloy substrate in a multi-arc ion plating vapor deposition system, then raise the temperature of the sample stage to 400°C, and guide the argon plasma to bombard and activate the surface of the substrate by applying a negative bias voltage, in which the argon gas The gas flow rate is 150 sccm, the bias voltage is -900V, and the processing time is 10 min.

[0059] (2) Multi-arc ion plating deposits nano-layer structure VAlCN / VN-Ag hard coating: V target, Ag target and Al target are selected as cathodes, and VAlCN / VN is deposited on the substrate by multi-arc ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com