DCPD (dicyclopentadiene) composite material for cover plates of air conditioners for vehicles

A technology for vehicle air conditioners and composite materials, applied in vehicle parts, air handling equipment, heating/cooling equipment, etc., can solve the problems of increasing vehicle energy consumption, unfavorable energy conservation and environmental protection, high density of glass fiber reinforced plastics, etc., to improve efficiency and reduce load. , Lightweight and durable material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The weight ratio of raw materials for vehicle air conditioner cover composite materials is as follows:

[0025] Material A DCPD 94% Tungsten hexachloride 5.6% Oxygen stabilizer 0.2% Glass fiber 0.2% Material B DCPD 92% Triethylaluminum 7.4% Benzophenone 0.6%

[0026] Preparation of vehicle air conditioner cover:

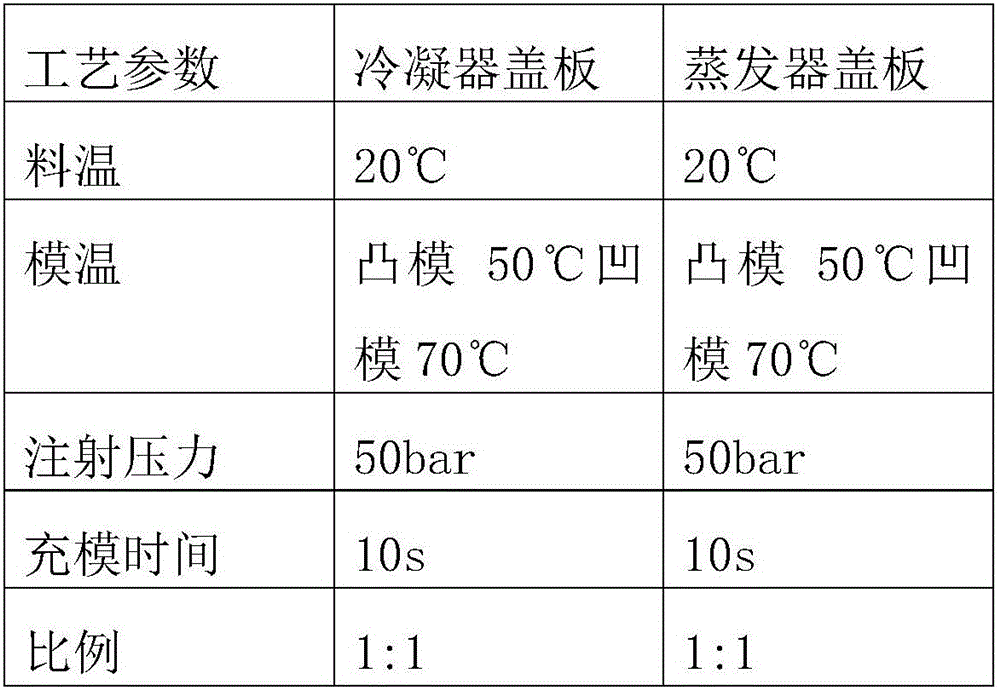

[0027] First mix A and B materials according to the mass ratio, control the material temperature to 20±2°C, control the flow rate of A and B materials to A:B=1:1, and the mixing time is 5±2 seconds, then fill the mold, and the female mold The mold temperature is 70±3°C, the male mold temperature is 50±3°C, the injection pressure is 50±5bar when filling the mold, the filling time is 10±2 seconds, and the mold is released after 25 seconds of curing and setting. If the part has flash, further modify the part. The vehicle air-conditioning cover plate prepared by the invention is better than the FRP molding in terms of aesthetics...

Embodiment 2

[0029] The weight ratio of raw materials for vehicle air conditioner cover composite materials is as follows:

[0030] Material A DCPD 88% Elemental tungsten 8% Alkene stabilizer 1% Glass Fiber 3% Material B DCPD90% Triethylaluminum 5% Benzophenone 5%

[0031] Preparation of vehicle air conditioner cover:

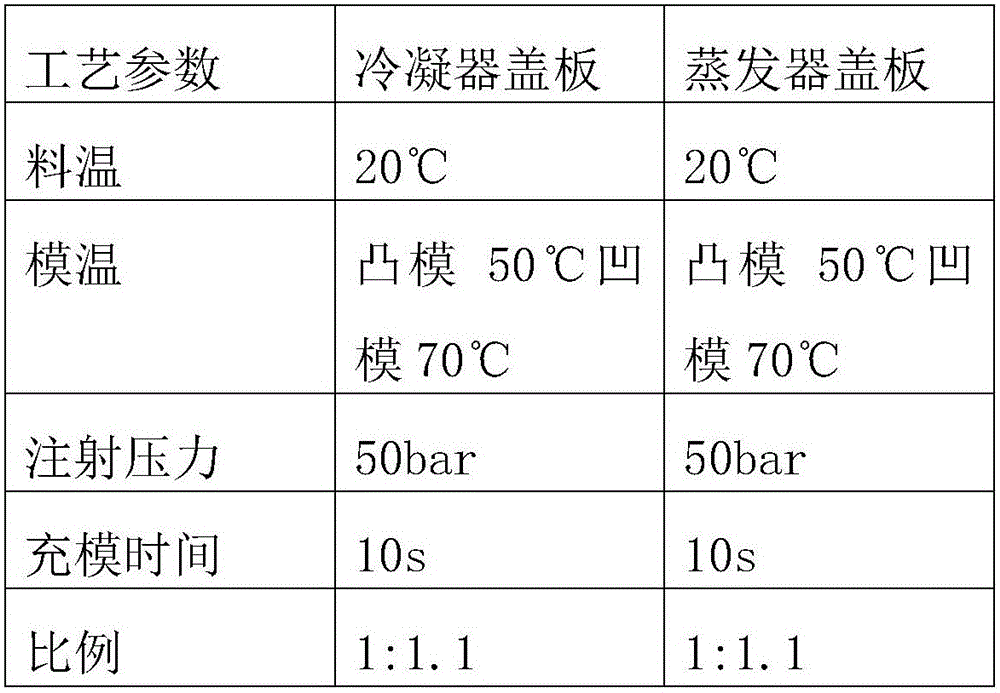

[0032] First mix A and B materials according to the mass ratio, control the material temperature to 20±2°C, control the flow rate of A and B materials to A:B=1:1.2, and the mixing time is 5±2 seconds, then fill the mold, the female mold The mold temperature is 70±3°C, the male mold temperature is 50±3°C, the injection pressure is 50±5bar when filling the mold, the filling time is controlled to be 10±2 seconds to fill the mold, and the mold is ready after 30 seconds of curing and setting. If the part has flash, further modify the part. The vehicle air-conditioning cover plate prepared by the invention has better aesthetics and consistency ...

Embodiment 3

[0034] The ratio of raw materials by weight of the air-conditioning cover plate composite material for vehicles is as follows:

[0035] Material A DCPD 85 copies Lithium manganite 8 parts 2 parts clay stabilizer 3 parts glass fiber Material B DCPD 87 copies 8 parts of triethylaluminum 3 parts benzophenone

[0036] Preparation of vehicle air conditioner cover:

[0037]First mix A and B materials according to the mass ratio, control the material temperature to 20±2°C, control the flow rate of A and B materials to A:B=1:1.2, and the mixing time is 5±2 seconds, then fill the mold, the female mold The mold temperature is 70±3°C, the male mold temperature is 50±3°C, the injection pressure is 50±5bar when filling the mold, the filling time is controlled to be 10±2 seconds to fill the mold, and the mold is ready after 30 seconds of curing and setting. If the part has flash, further modify the part. The vehicle air-conditioning cover plate prepared b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com