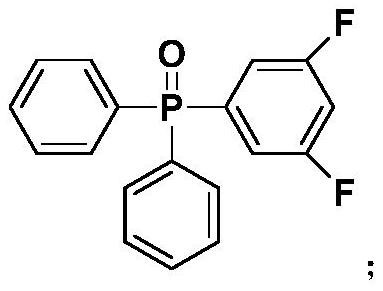

Preparation method of (3, 5-difluorophenyl) diphenylphosphine oxide

A technology of diphenylphosphine oxide and difluorophenyl is applied in the field of preparation of diphenylphosphine oxide, which can solve the problems of single structure and few types of polymers, and achieves high safety, easy modification and excellent oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A preparation method of (3,5-difluorophenyl) diphenylphosphine oxide, comprising:

[0021]

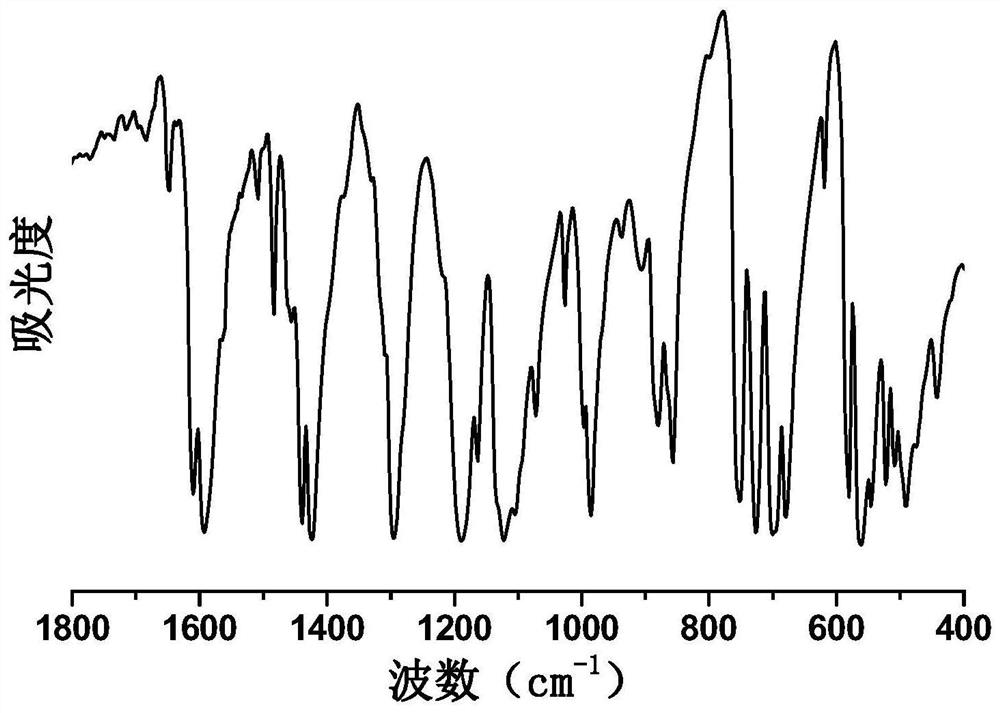

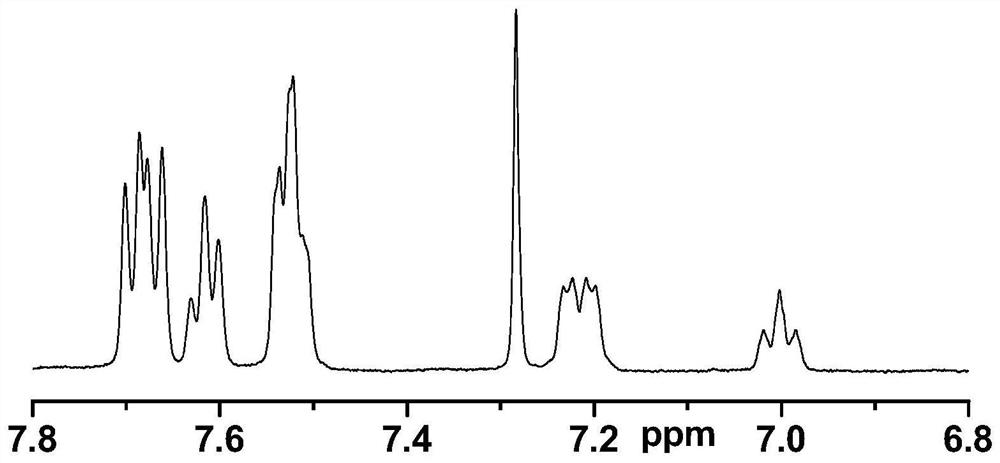

[0022] The preparation method comprises: adding 1-bromo-3,5-difluorobenzene solution into a reaction solvent containing magnesium powder, and performing a Grignard reaction at 0° C. to room temperature for 2-6 hours in a nitrogen or argon atmosphere to obtain 3,5-difluorophenylmagnesium(II) bromide; then mix 3,5-difluorophenylmagnesium(II) bromide with diphenylphosphine chloride solution and react at 0°C to room temperature for 8 -16h, after quenching the reaction with 0.5-1.5mol / L dilute sulfuric acid, dilute hydrochloric acid or dilute phosphoric acid, the light brown oily product is obtained through the first purification treatment; finally, the light brown oily product is treated with hydrogen peroxide or tert-butyl hydroperoxide Oxidation, and after the second purification treatment, (3,5-difluorophenyl) diphenylphosphine oxide is obtained.

[0023] Wherein, the 1-bromo...

Embodiment

[0026] A preparation method of (3,5-difluorophenyl) diphenylphosphine oxide, comprising:

[0027]

[0028] 1) In a 250mL round-bottomed flask equipped with a stirring bar, an addition funnel, a condenser and a gas inlet, continuously feed nitrogen gas, and add 1.2715g of Mg scraps and 20mL of tetrahydrofuran to fully immerse the Mg scraps in tetrahydrofuran, and then add 100mL of Containing 10.6743g of 1-bromo-3,5-difluorobenzene in tetrahydrofuran solution, and continuously stirring at room temperature for 4h to obtain 3,5-difluorophenylmagnesium bromide solution;

[0029] 2) Add 3,5-difluorophenylmagnesium bromide solution dropwise to 50mL tetrahydrofuran solution containing 11.2953g diphenylphosphine chloride through the addition funnel at 0°C, and the resulting reaction mixture was stirred overnight (12h) , was added to 100mL 1M hydrochloric acid to quench;

[0030] 3) Dilute the obtained reaction product mixture with 300mL ethyl acetate, and transfer to a separatory f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com