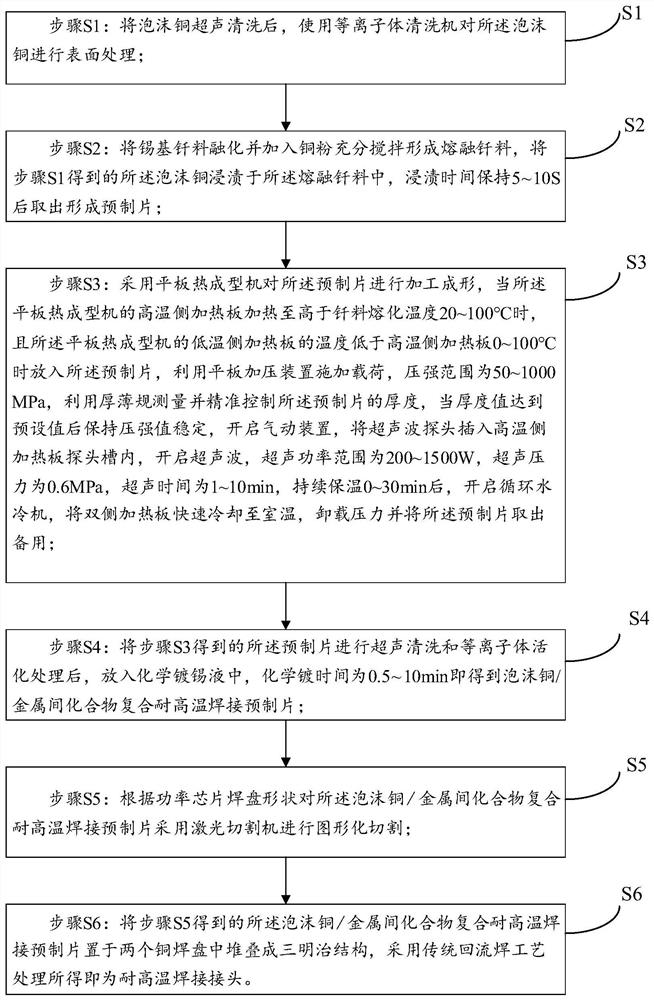

A low-temperature rapid pressure-free manufacturing method for high-temperature-resistant joints for power chip packaging

A power chip and manufacturing method technology, applied in the direction of manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of high welding temperature, long welding time, poor reliability of joints, etc., and achieve excellent electrical conductivity, less internal defects, and good reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

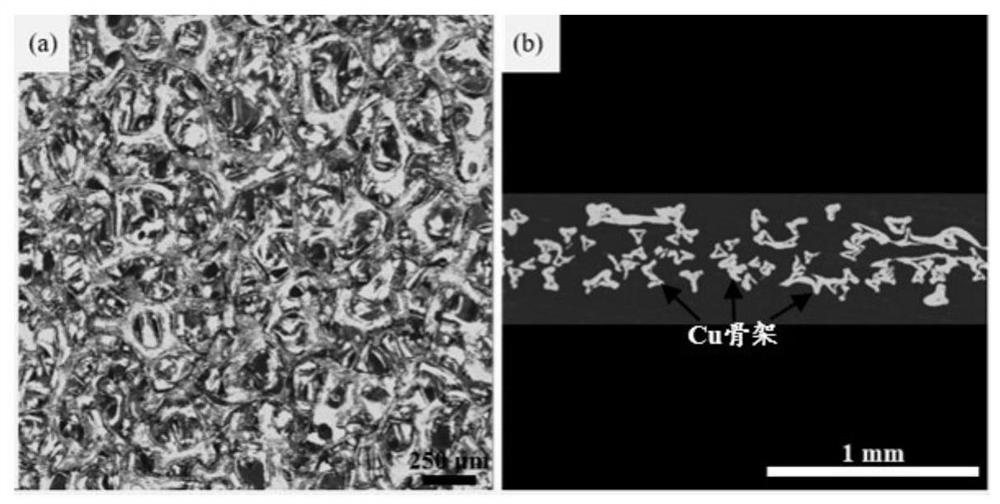

[0042] Select commercial copper foam with a pore size of 150 μm, a porosity of 63.1%, and a thickness of 100 μm, and cut it into 10×10mm 2 For small square pieces, first use alcohol solution to ultrasonically clean it for 5 minutes, then use 5% hydrochloric acid alcohol solution to ultrasonically clean it for 1 minute, then use deionized water to ultrasonically clean it for 1 minute and dry it with nitrogen, and finally use argon plasma to clean it. Machine cleaning for 10 minutes, power range 100W. Melt the tin-copper eutectic solder in the molten pool, add an appropriate amount of copper powder (1kg solder to 10-50g copper powder) and stir well, keep the temperature at 240°C, scrape off the surface oxide film, clean the plasma and The foamed copper without flux added is quickly immersed in the molten solder, kept for 5 seconds, then taken out, cooled to room temperature with water, and dried with cold air.

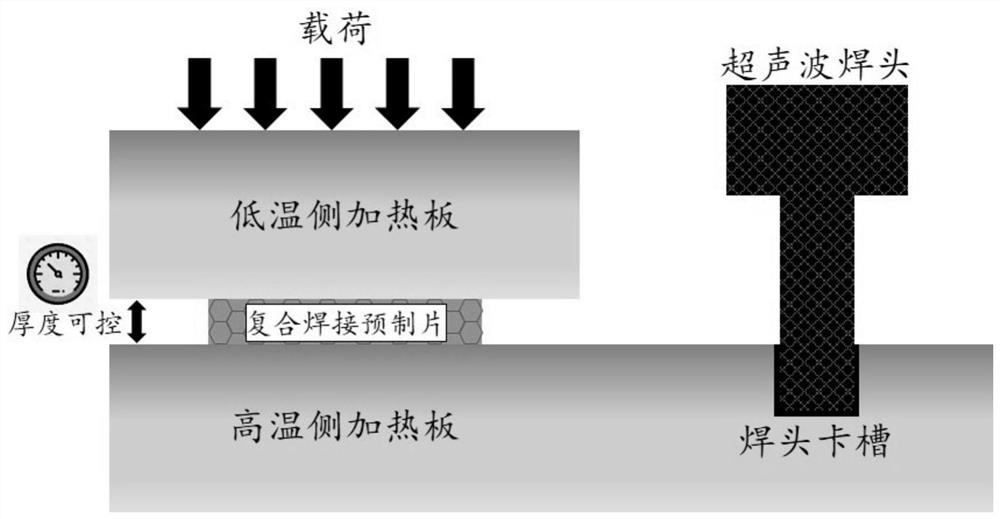

[0043] Using a flat-plate thermoforming machine with independent t...

example 2

[0046] The preparation process of the copper foam / intermetallic compound composite high-temperature-resistant welding prefabricated sheet similar to Example 1 was adopted. Using a flat-plate thermoforming machine with independent temperature control on both sides and the ability to apply ultrasonic loads, set the heating plate on the low temperature side to 200°C and the heating plate on the high temperature side to 240°C; when the temperature rises to the predetermined temperature, place the prefabricated sheet on the Between the plates, the pressure is 400MPa, so that the thickness of the prefabricated sheet reaches 50μm; when the thickness value reaches the preset value, keep the pressure value stable, turn on the pneumatic device, insert the ultrasonic probe into the probe groove of the heating plate on the high temperature side, turn on the ultrasonic wave, and the ultrasonic power The ultrasonic pressure is 1200W, the ultrasonic pressure is 0.6MPa, and the ultrasonic time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com