Spray deposition 3D printing device based on self-excitation electrostatic field driving, working method and application of working method of spray deposition 3D printing device based on self-excitation electrostatic field driving

A technology of jet deposition and 3D printing, applied in the field of 3D printing, can solve the problems of limited nozzle material, difficult to print stably, and the extraction electrode does not fit, and achieves the effect of ensuring the accuracy of the experiment, increasing the stability, and making the production simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

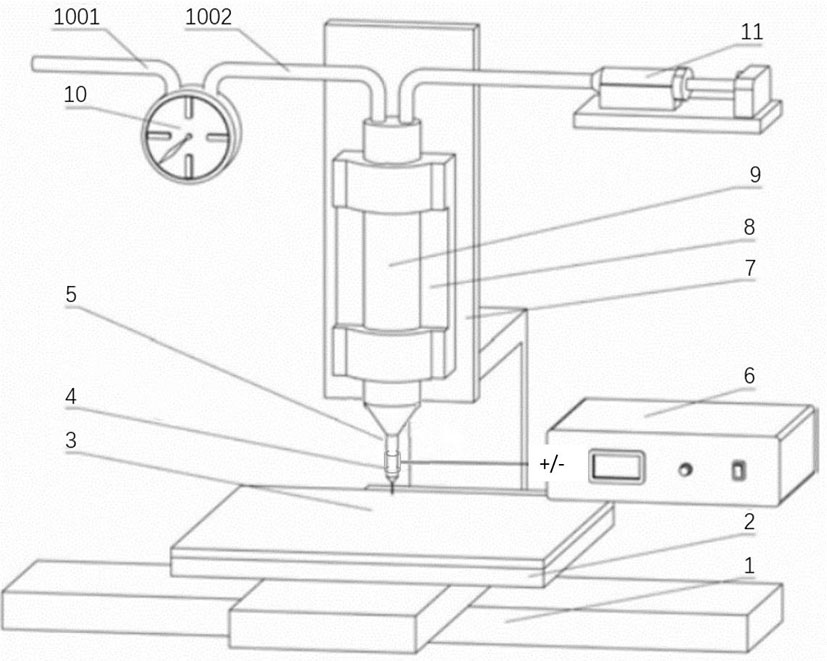

Embodiment 1

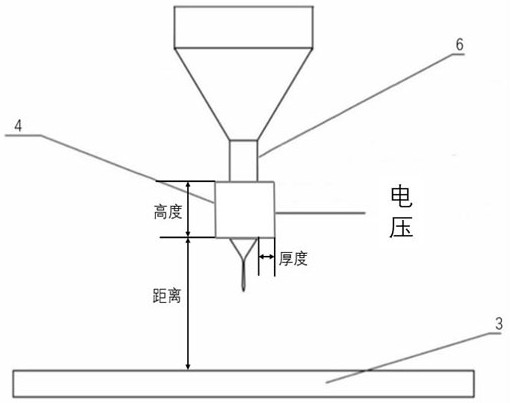

[0031]The printing material is nano-silver paste, the main parameters are spherical silver particles with an average diameter of 300nm, a solid content of 60wt.%, and a viscosity of 1300cP s; the silver paste is composed of organic solvents, thickeners, surfactants and dispersedly distributed silver nanoparticles Composition: The thickness of the extraction electrode is 35 μm, the height is 1 mm, the distance from the substrate is 2.5 mm, and the substrate material is PET.

[0032] The specific working method is as follows:

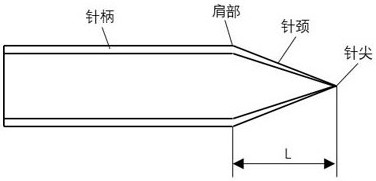

[0033] Step 1: Make a nozzle with an inner diameter of 15 μm, use a needle puller, a needle forger, and a glass capillary to make a glass nozzle with the same needle neck length, and install the nozzle on the nozzle;

[0034] Step 2: Printing initialization, put the nano-silver paste into the storage tank, move the X-Y worktable and Z-direction worktable from the original position to the printing station, and move the bottom end of the nozzle of the print...

Embodiment 2

[0039] The printing material is nano-silver paste, the main parameters are spherical silver particles with an average diameter of 300nm, a solid content of 80wt.%, and a viscosity of 2400cP s; the silver paste is composed of organic solvents, thickeners, surfactants and dispersedly distributed silver nanoparticles Composition: The extraction electrode has a thickness of 35 μm, a height of 1 mm, and a distance of 2.5 mm from the substrate, and the substrate material is glass.

[0040] The specific working method is as follows:

[0041] Step 1: Make a nozzle with an inner diameter of 30 μm, use a needle puller, a needle forger, and a glass capillary to make a glass nozzle with the same neck length, and install the nozzle on the nozzle;

[0042] Step 2: Printing initialization, put the nano-silver paste into the storage tank, move the X-Y worktable and Z-direction worktable from the original position to the printing station, and move the bottom end of the nozzle of the print head...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com