Forming process for low-temperature NOx rapid alternate adsorption-regeneration catalyst

A technology for regenerating catalyst and molding process, which is applied in catalyst regeneration/reactivation, physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, etc., which can solve the problem that the denitration process cannot be carried out continuously and NO adsorption capacity is weak. , low NOx adsorption efficiency, etc., to achieve good NOx adsorption performance, promote nitrogen oxides, and improve adsorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] (1) Dissolve 2g of copper nitrate, 10g of cerium nitrate, 10g of manganese nitrate, 10ml of citric acid, and 0.5g of alumina in water, stir well, add an appropriate amount of hydrogen peroxide to make the pH of the solution 4.5, and then dry at 110°C for 12 hours. The solid obtained after drying was extruded at 2.5MPa, crushed, sieved to obtain catalyst particles of 20-40 mesh, and finally calcined at 200°C and 550°C for 3 hours respectively;

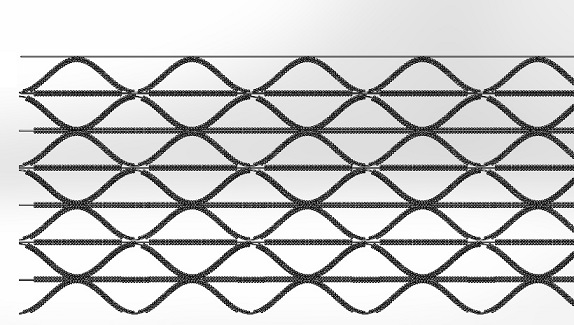

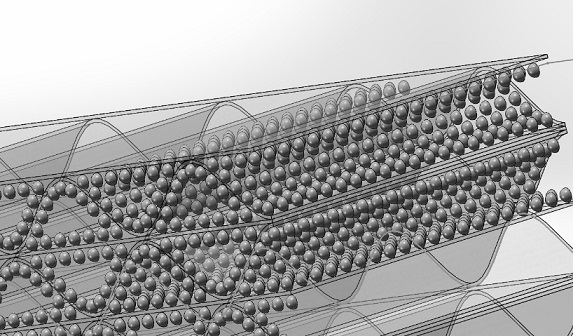

[0039] (2) Extrude the glass fiber paper into a wave shape at 500°C, wherein the distance between the two peaks of the wave-shaped corrugated paper is 0.25cm, and the peak height is 0.15cm, and coat the glass fiber paper with a concentration of 30% Aluminum sol, and quickly dried at 300°C;

[0040] (3) Disperse the catalyst obtained in step (1) into 50% aluminum sol, the molar ratio of composite metal oxide catalyst to aluminum sol is 3.5:8.5, and brush it on the surface of glass fiber paper in step (2);

[0041](4) The corrugat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com