Preparation method of fermented rose sauce rich in gamma-aminobutyric acid

A technology of aminobutyric acid and rose sauce, applied in sterilization methods, biochemical equipment and methods, methods of supporting/immobilizing microorganisms, etc. In order to shorten the fermentation cycle, retain nutrients and medicinal effects, and enrich nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

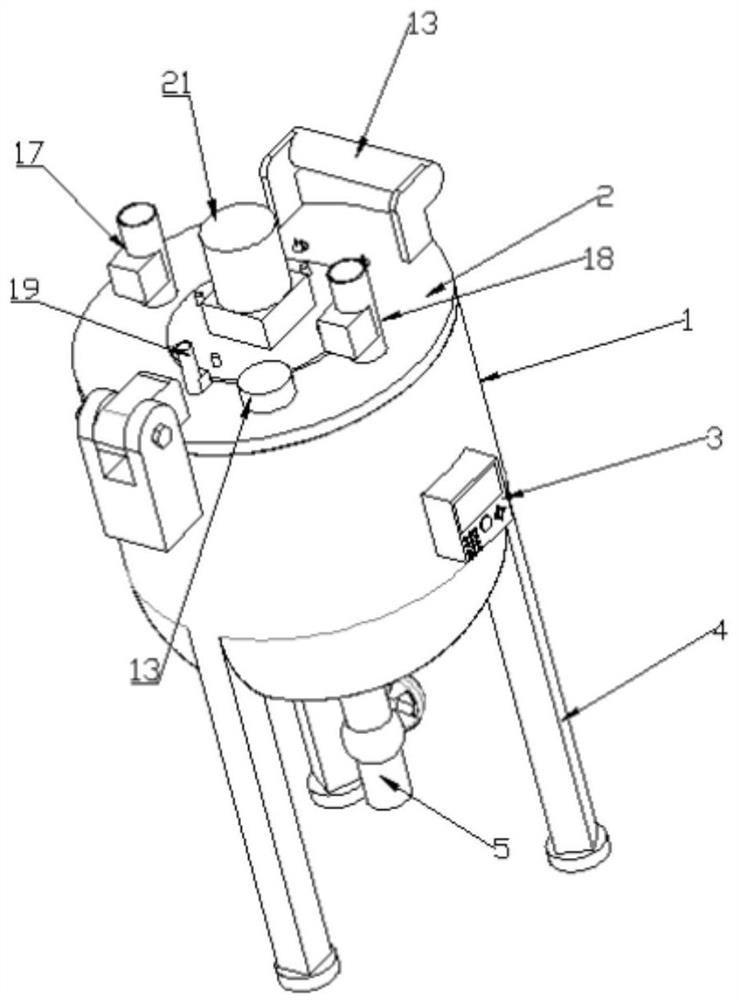

Image

Examples

Embodiment 1

[0050] A preparation method rich in gamma-aminobutyric acid fermented rose sauce, specifically comprising the following steps:

[0051] (1) Strain activation: Under the condition of aseptic operation, transfer the strain of Pleurotus osmanthus preserved at 4°C to PDY solid medium, and culture it in a constant temperature incubator at 25°C for 7 days until the diameter of the colony grows to 9cm. About half of the petri dish, and when the aerial hyphae are vigorous, the activated chrysanthemum strain is obtained.

[0052] (2) Use dry double rose petals as the medium raw material, add water (solid-liquid ratio 1:2) to dry double rose petals, add polydextrose and glutamic acid, mix well, sterilize at 121°C for 15 minutes, cool, Inoculate the edible fungus Pleurotus chinensis, the inoculum amount is 5g / kg, and cultivate in the dark at 25°C for 6 days for later use.

[0053] (3) After the fermentation is over, the solid-state fermented product and water have a solid-liquid ratio o...

Embodiment 2

[0061] The other conditions of this embodiment are the same as those of Example 1, except that: the dry double rose petals and water are in a solid-liquid ratio of 1:1, 1:1.5, and 1:2, adding 0.5% polydextrose and 2.5% glutamic acid, mixing Evenly, sterilized at 121°C for 15 minutes, cooled, inoculated with the edible fungus Pleurotus osmanthus, and cultured in the dark at 25°C for 6 days for later use; the mycelium and the culture materials were dried at 60°C together, crushed, and the GABA production was measured.

[0062] Quantitative determination of GABA content was carried out by high performance liquid chromatography. Figure 9 It can be seen that the double-petal rose and water are solid-state fermented according to the material-liquid ratio of 1:1, 1:1.5, and 1:2. The mycelium growth of the edible fungus Xiuzhen mushroom is basically the same, and the 1:1 mycelium grows best, and the 1:1 mycelium grows best. At 2 o'clock, the GABA content was the highest, indicating t...

Embodiment 3

[0064] The other conditions of this example are the same as Example 1, the difference is: dry double rose petals and water at a solid-liquid ratio of 1:1, add 0.5% polydextrose, 2.5% glutamic acid, mix well, sterilize at 121°C for 15min Afterwards, cool down, inoculate the edible fungus Pleurotus chinensis, and culture in the dark at 25°C for 3, 4, 5, 6, 7, and 8 days for later use; the mycelia and the culture materials are dried at 60°C together, crushed, and the GABA production is measured.

[0065] Depend on Figure 10 It can be seen that with the prolongation of the fermentation time, the growth of the mycelia of the edible fungus Pleurotus chinensis is getting better and better. After the 6th day of fermentation, the growth of the mycelium has little change, and the GABA content in the fermented rose reaches the maximum on the 7th day. There was little difference in GABA content at 6, 7, and 8 days of fermentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com