Preparation method and application of coated granules

A technology for coating granules and polyethylene glycol, which is used in the fields of food, feed processing, and pharmaceuticals, can solve problems such as the influence of enzyme activity or bacterial activity, the inability to isolate various materials, and the influence of activity and stability, so as to improve activity and stability. Stability, good processing stability, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example provides a kind of coated microelement granules (applied to pig feed), prepared according to the following process, and the specific formula is as follows:

[0027] Names of raw materials and auxiliary materials parts by weight Ferrous Sulfate Monohydrate 20 copies Copper Sulfate Pentahydrate 10 copies Manganese Sulfate Monohydrate 10 copies Zinc Sulfate Monohydrate 10 copies Sodium Selenite 5% 1 copy Potassium iodate 5% 1 copy Chromium picolinate 1.2% 1 copy Cobalt Sulfate Monohydrate 5% 2 copies stearic acid 10 copies palm oil 25 copies Glyceryl behenate 5 copies Hypromellose (K4M) 5 copies

[0028] (1) Weigh the above-mentioned granulation materials, glyceryl behenate, hypromellose, and heat-sensitive materials, place them in a mixer, and mix them for 10 minutes to obtain uniformly mixed materials;

[0029] (2) Rolling and granulating the uniformly mixed mat...

Embodiment 2

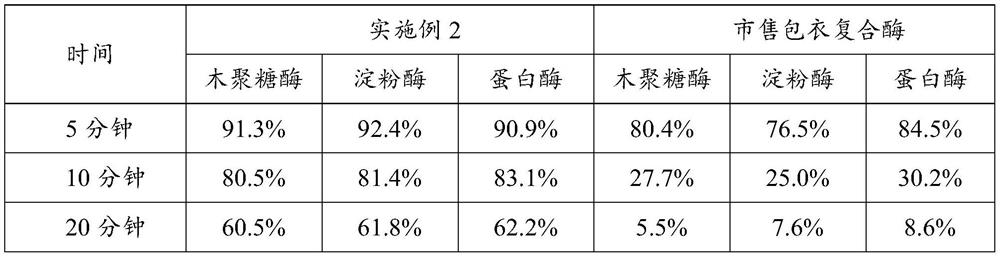

[0031] This embodiment provides a coated composite enzyme granule, based on the above preparation process, specifically as follows:

[0032] Names of raw materials and auxiliary materials parts by weight Xylanase 18 copies cellulase 10 copies protease 10 copies amylase 10 copies Lipase 1 copy Mannanase 1 copy stearic acid 20 copies polyethylene glycol 4000 15 copies Glyceryl behenate 10 copies Hypromellose (K100M) 0.5 parts Hypromellose (E5) 4.5 servings

[0033] (1) Weigh the above-mentioned granulation materials, glyceryl behenate, hypromellose, and heat-sensitive materials, place them in a mixer, and mix them for 20 minutes to obtain uniformly mixed materials;

[0034] (2) Rolling and granulating the uniformly mixed material, the rolling time is 30 minutes, the temperature is controlled at 60° C., and slow-release granules are obtained by extrusion. Particles of 0.3-1.2 mm are collec...

Embodiment 3

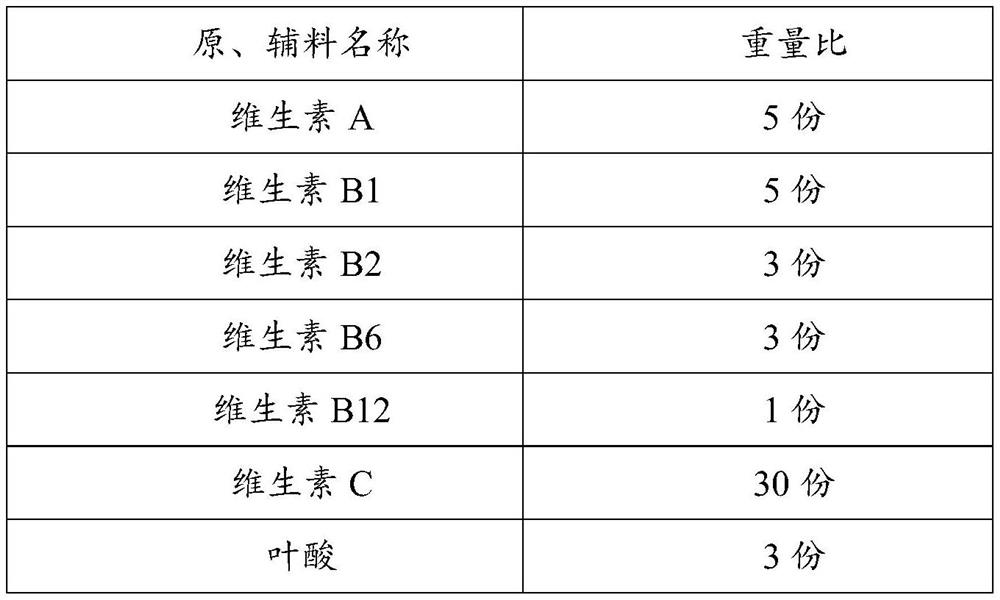

[0036] This embodiment provides a kind of coated vitamin granule, which is prepared by the following process, specifically as follows:

[0037]

[0038]

[0039] (1) Weigh the above-mentioned granulation materials, glyceryl behenate, hypromellose, and heat-sensitive materials, place them in a mixer, and mix them for 10 minutes to obtain uniformly mixed materials;

[0040] (2) The homogeneously mixed material is subjected to rolling granulation, the rolling time is 60 minutes, the temperature is controlled at 60° C., and slow-release granules are obtained by extrusion. Particles of 0.3-1.2 mm are collected by sieving to obtain sieved particles.

[0041] Particles of 0.3-1.2 mm are collected by sieving to obtain sieved particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com