Carbon-based anchored non-noble metal monatomic catalyst as well as preparation method and application thereof

A non-precious metal and catalyst technology, applied in the field of carbon-based anchored non-precious metal single-atom catalysts, can solve the problems of restricting the use of aM, and achieve the effects of less pollution to the environment, simple preparation process, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

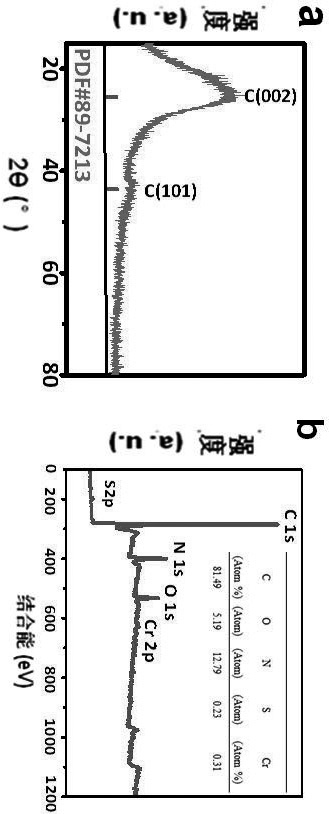

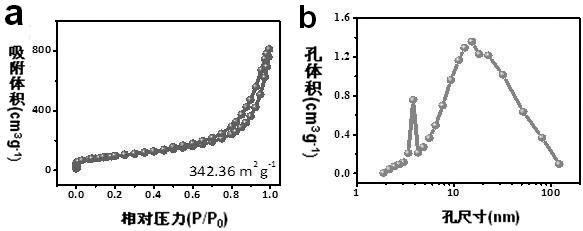

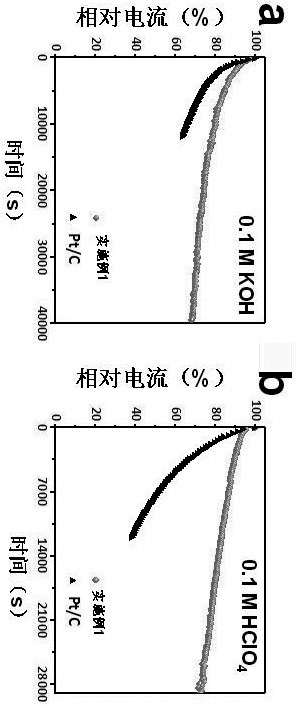

[0037] A method for preparing a carbon-based anchored non-noble metal single-atom catalyst, comprising the steps of:

[0038] 1) In a 100mL beaker, weigh 5g of melamine, 0.5g of surfactant P123 and 0.15g of N-acetyl-L-cysteine into 50mL of deionized water, stir at 60°C for 30 min, and the stirring speed is 720 rpm, to form a homogeneous suspension;

[0039] 2) Dry the suspension obtained in step 1) in a constant temperature drying oven at 60°C for 24 h;

[0040] 3) Carbonization: The product obtained in step 2) is heated to 900°C for 360 min at a rate of 10°C / min in a nitrogen atmosphere (gas flow rate is 60 sccm) and carbonized for 360 min, and then naturally cooled to room temperature to obtain carbon-deficient porous nanostructures. piece;

[0041]4) Add 300mg of carbon-deficient porous nanosheets and 10mg of chromium chloride into 40mL of ethanol, stir at room temperature for 24 hours, then add the obtained samples into four centrifuge tubes, add 10ml to each centrifug...

Embodiment 2

[0048] The difference with Example 1 is: in step 1), melamine is changed into urea; other steps are all the same as Example 1.

Embodiment 3-4

[0050] The difference from Example 1 is that in step 2), the drying temperature is changed to 80° C. and 120° C. in turn; other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com