Long nozzle for pouring basket metallurgy and application thereof

A long nozzle and tundish technology, which is applied in the field of iron and steel metallurgy, can solve the problems of insufficient time for alloy elements to fully diffuse, uneven distribution, and late addition time, and achieve the effects of improving stable yield, uniform distribution, and enhanced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

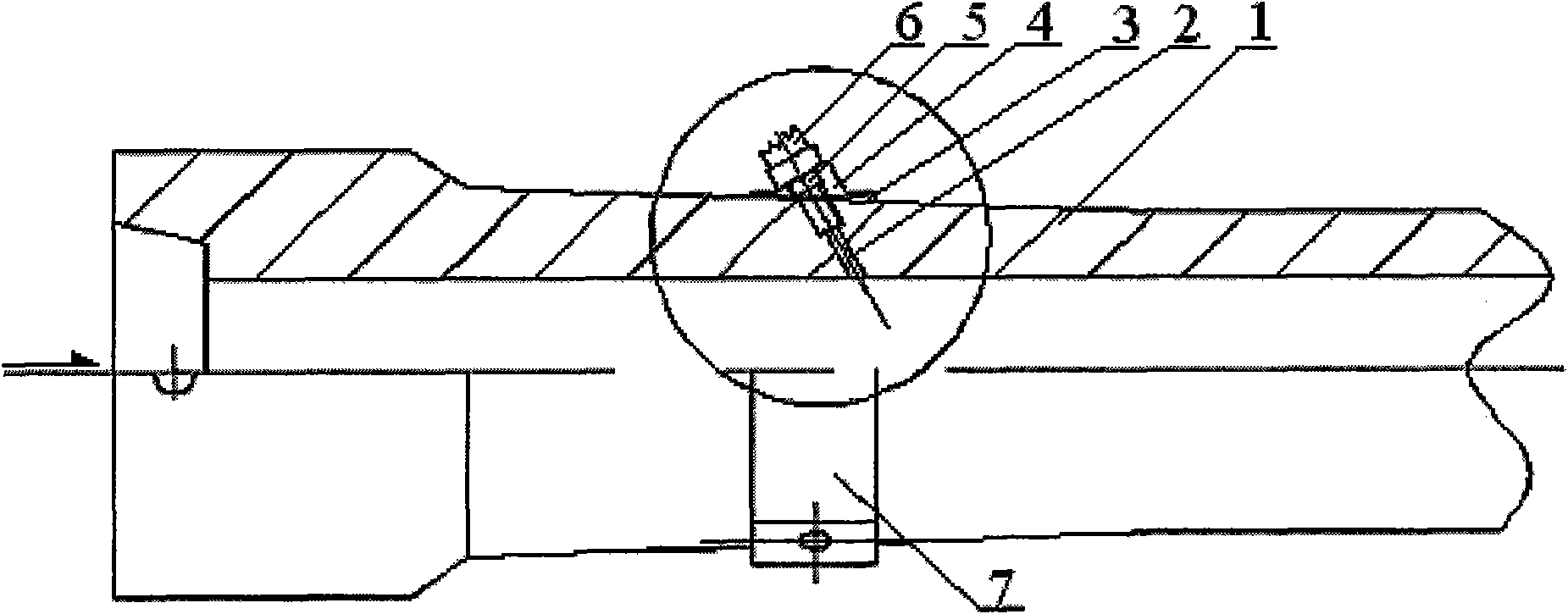

[0020] In this embodiment, the position of the through hole 2 of the shroud for metallurgy in the tundish is 100 mm from the top of the shroud, the number of the through hole 2 is 1, the diameter of the hole located on the inner wall of the shroud is 10 mm, and the length is 10 mm, and the hole located on the outer wall of the shroud The diameter is 20mm, the axial direction of the through hole and the axial direction of the upper long nozzle form an included angle of 10°, the outer diameter of the front part of the joint 5 is 20mm, and the inner diameter is 10mm.

[0021] When used to remove small inclusions, the steps are as follows:

[0022] A two-strand slab continuous casting machine is adopted, the section of the casting slab is 1150×230mm, and the casting speed is 1.2m / min. Connect the metal hose (external delivery pipe) 6 to the gas source, blow in argon, the gas supply pressure is 2 atm, and the flow rate is 50 l / min. The argon gas is fully dispersed by the stream in...

Embodiment 2

[0024]In this embodiment, the position of the through hole 2 of the shroud for metallurgy in the tundish is 160 mm from the top of the shroud, and the number of the through holes 2 is 2, distributed along the radial direction of the shroud, and the angle between the two through holes 2 is 180°. The diameter of the hole located on the inner wall of the shroud is 8 mm, and the length is 12 mm. The diameter of the hole located on the outer wall of the shroud is 30 mm. 30mm with an inner diameter of 25mm.

[0025] When used to remove fine inclusions, the following steps are included:

[0026] A two-strand slab continuous casting machine is adopted, the section of the casting slab is 1150×230mm, and the casting speed is 1.2m / min. Connect the metal hose (external delivery pipe) 6 to the gas source, blow in argon, the gas supply pressure is 6 atm, and the flow rate is 300 l / min. The argon gas is fully dispersed by the stream in the shroud, and a large number of dispersed micro-bubb...

Embodiment 3

[0028] In this embodiment, the number of shroud through-holes 2 for metallurgy in the tundish is six, which are asymmetrically and arbitrarily distributed along the shroud space. The position of the uppermost through hole 2 is 80mm from the top of the long nozzle, and the position of the lowermost through hole 2 is 500mm from the top of the nozzle. The hole located on the inner wall of the shroud has a diameter of 25 mm and a length of 0 mm, and the hole located on the outer wall of the shroud has a diameter of 25 mm and a length of 60 mm. The axial direction of the through hole 2 forms an included angle of 40° with the axial direction of the upper part of the shroud, and the outer diameter of the front part of the joint 5 is 25 mm, and the inner diameter is 14 mm.

[0029] When used to remove fine inclusions, the following steps are included:

[0030] A two-strand slab continuous casting machine is adopted, the section of the casting slab is 1150×230mm, and the casting speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com