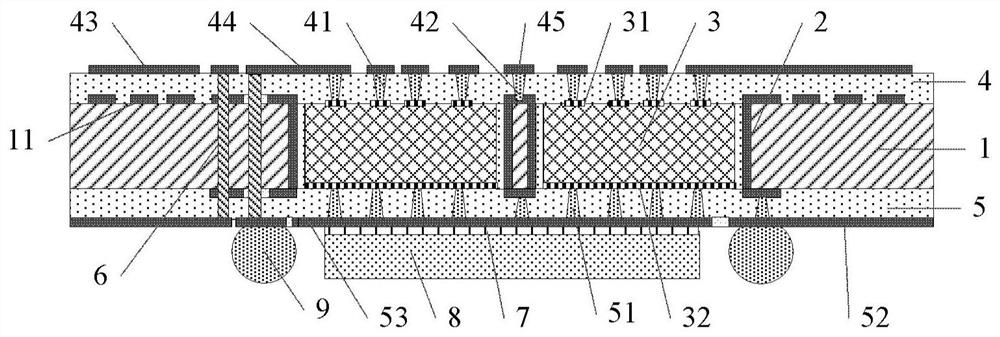

Embedding and packaging structure for organic substrate integrated with antenna and radio frequency front end

A radio frequency front-end, packaging structure technology, applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve problems such as electromagnetic interference, limit antenna performance, and metal heat sink heat dissipation methods are no longer applicable, and improve antenna performance. Bandwidth, effect of reducing parasitics and transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

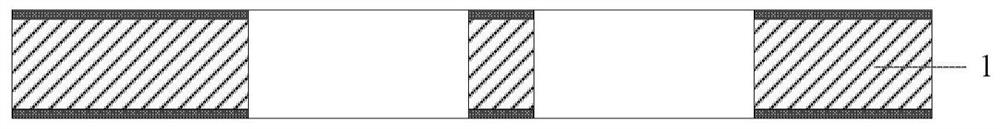

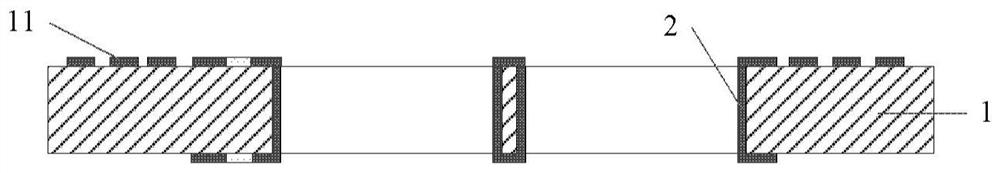

[0048] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0049] In the present invention, "disposed on" or "attached to" is used to include a direct contact relationship with a single or multiple components. For example, the No. 2 dielectric layer is arranged on the lower surface of the core board, which means that the No. 2 dielectric layer is in direct contact with the core board, that is, the No. 2 dielectric layer is in direct contact with the lower surface of the core board. Moreover, the ordinal numbers used in the specification and claims, such as "first", "second", "number one" or "number two", are used to modify the components claimed for protection, which do not themselves contain and represent the Parts have any previous ordinal numbers, nor do they imply the order o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com