Sound absorption type soft reinforced thermal insulation wallboard and manufacturing process thereof

A thermal insulation wallboard and manufacturing process technology, which is applied in the field of plate processing, can solve the problems of poor performance, impact resistance of glue opening and deformation, high production cost, etc., and achieve the effect of improving contact surface, anti-glue deformation and buffering capacity, and saving processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

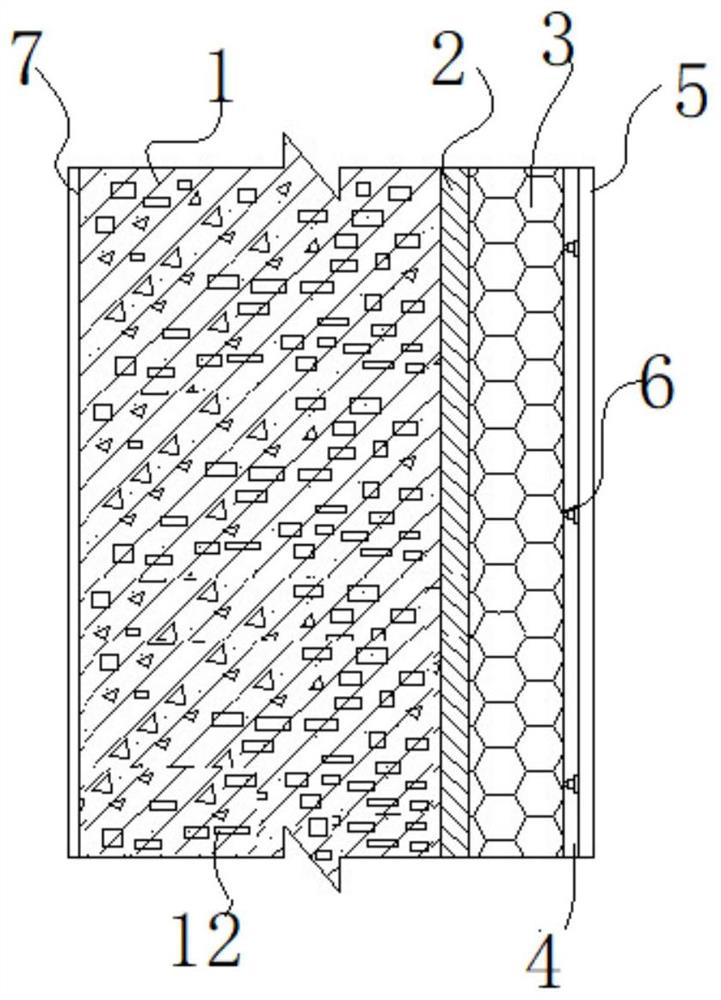

[0043] like figure 1 FIG sound absorbing soft type present embodiment reinforcing wall insulation, comprising a sound absorbing layer and an outer profile of the inner laminate 7, the flexible substrate 1, the fiber fabric layer 2, insulating layer 3, the reinforcing layer 4 and the decorative layer 5. Fiber fabric layer 2 and the yarn is woven aramid fibers are mixed; the lamination distribution can be dipped first fabric web layers 2, 3 vertically while increasing the frictional force between the flexible substrate 1 and the insulation layer, in turn two We are firmly adhered in the horizontal direction.

[0044] Embodiment of the present sound absorbing type flexible reinforced wall insulation embodiment, flexible substrate 1 may not be used any wood component, which component comprises a calcium powder, green powder, polyvinyl chloride, and the resin powder feed back accounted for about 70% , regrind refers prepared under the angle plate process, can be recycled; green powder ...

Embodiment 2

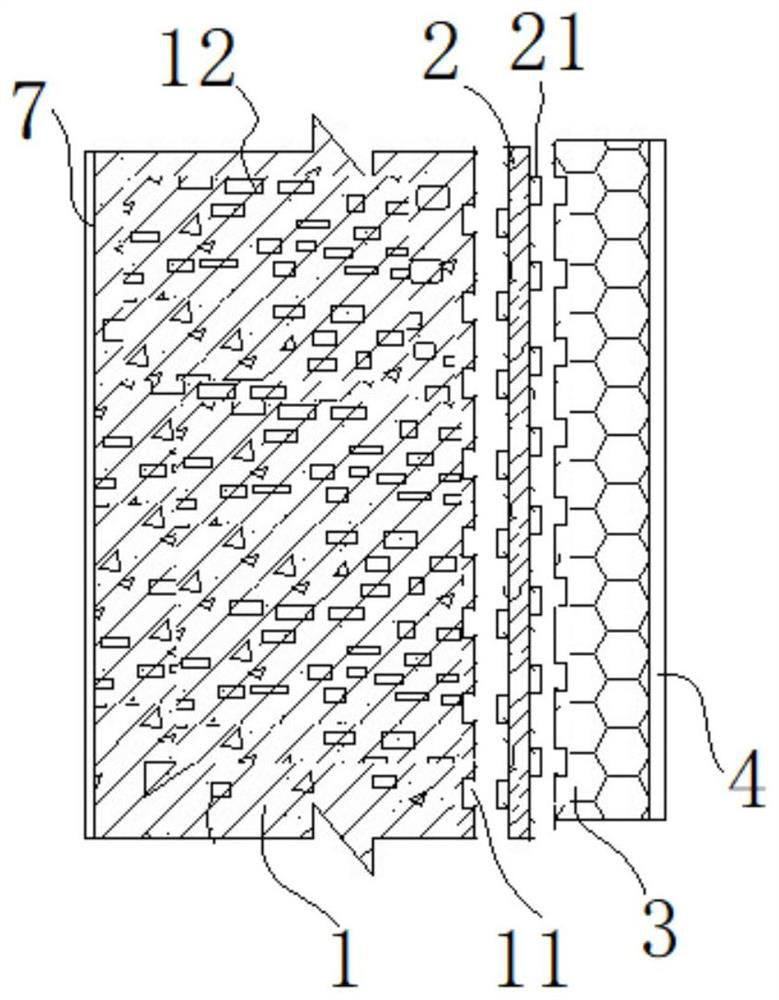

[0047] Sound absorbing soft type present embodiment strengthening wall insulation, is the further improvement on the embodiment of the embodiment 1, the substrate 1 soft roll forming a soft plastic sheet retentate, i.e. the flexible substrate 1 is extruded base when rolling, the binder can be glue bleed, so that, when the fiber fabric layer 2 and the overlay, fiber fabric layer 2 without re-dipped, thus saving step, improve production efficiency; the insulating layer 3 polystyrene board or phenolic board, polystyrene board or phenolic board while ensuring the insulation effect, easily drawn fiber cloth glue layer 2, so as to achieve the technical effect of the three strongly bonded. Roll forming a soft blanket on the retentate surface of the engagement structure, the upper and lower surfaces of the fiber fabric layer 2 and the lower surface of the insulating layer 3 are adapted to each other, make full use of the characteristics of readily deformable random fiber fabric layer 2, t...

Embodiment 3

[0058] Sound absorbing soft type embodiment of the present embodiment and the reinforcing wall insulation manufacturing process, further improvements on the basis of the embodiment 2, after the step of glue can be first mixed and stalk segment 12 A, then the order of mixing additives and other after mixing the components, other components in Example 1 and the base 2 again, and then adding about 10% by weight of the polyethylene phase change microcapsules; stalk segment 12 and the first glue mixture, so lets gum was first straw is temporarily stored in the hollow core structure 12, particularly wheat straw, which bigger volume hollow, an amount more temporary glue such that, post-forming roll, the greater will be the amount of glue seeping . Phase change polyethylene polymer microcapsule shell material is polyethylene, paraffin oils prepared through the phase change material and aqueous phases, the shear homogenizer, a hydrothermal reaction was heated reactor, cooling step, the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com