Nanometer zinc oxide/artemisia annua volatile oil/epoxy resin high-performance antibacterial material and preparation method thereof

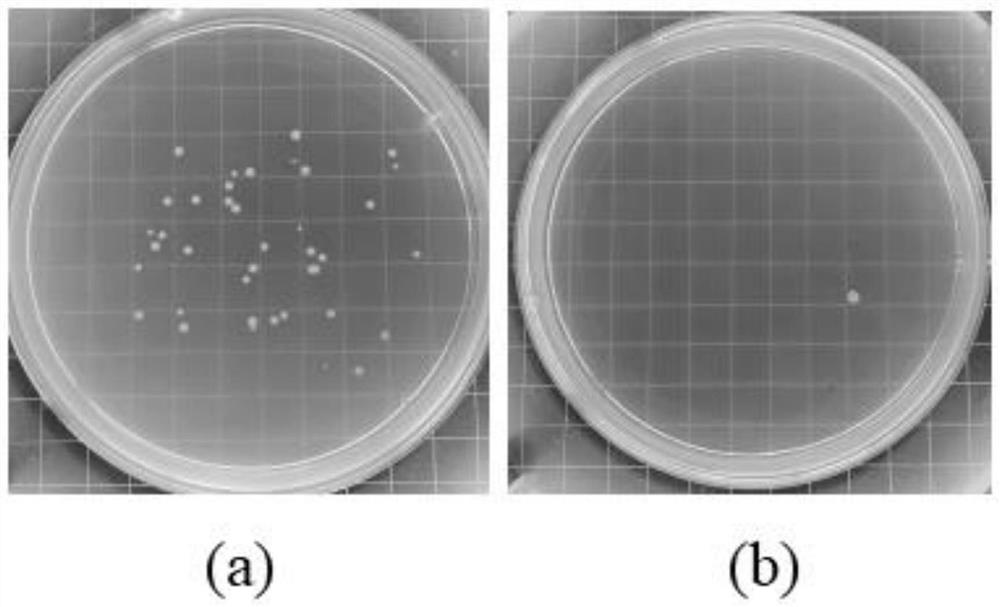

A technology of nano-zinc oxide and epoxy resin, which is applied in the field of high-performance antibacterial materials and its preparation, nano-zinc oxide/artemisia volatile oil/epoxy resin high-performance antibacterial materials and its preparation field, which can solve the problem that epoxy resin is easily infected by bacteria Corrosion and other problems, to achieve long-term antibacterial time, improve mechanical properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

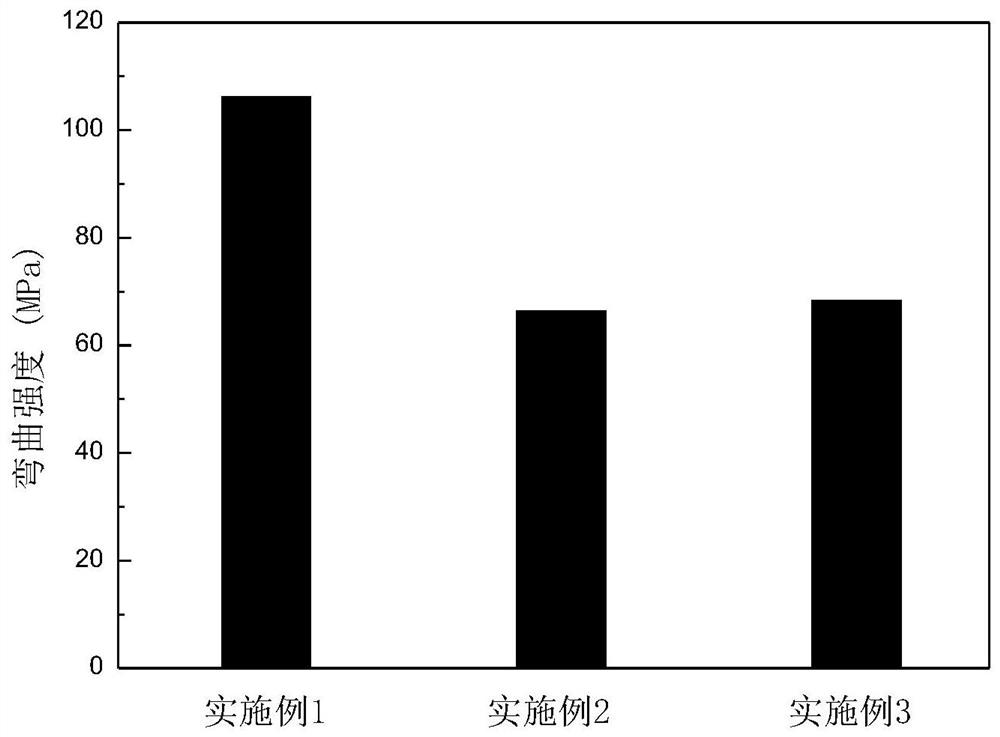

Embodiment 1

[0037] This embodiment provides a preparation method of nano-zinc oxide / artemisia annua volatile oil / epoxy resin composite material, comprising the following steps:

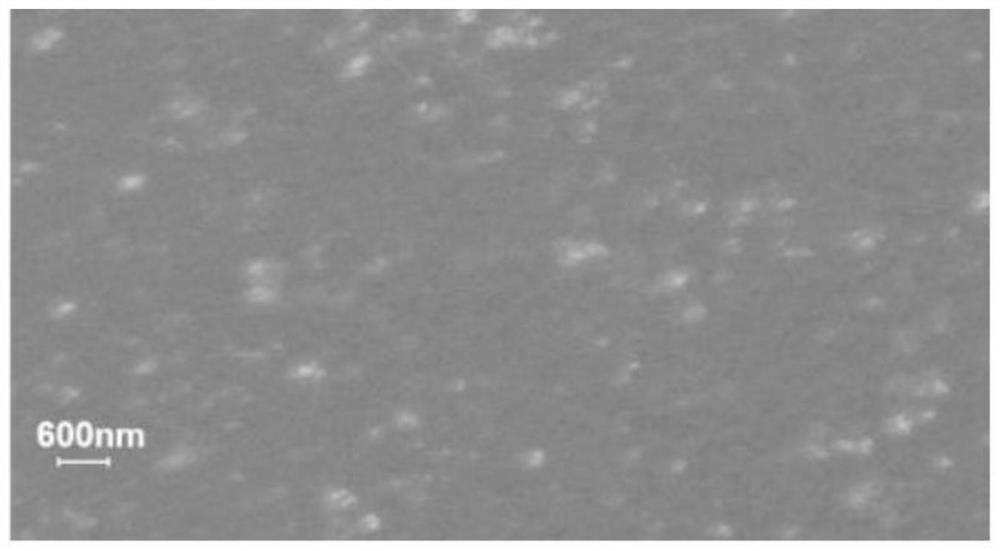

[0038] (1) Disperse nano-zinc oxide and γ-glycidyl etheroxypropyl trimethoxysilane in a mixed solution of water and absolute ethanol at a mass ratio of 30:1, then vacuum dry at 120°C for 2 hours, and cool Post-grinding to obtain surface-treated nano-zinc oxide;

[0039] (2) In parts by weight, add 0.45 part of Artemisia annua volatile oil in 48.8 parts of curing agent (methyl hexahydrophthalic anhydride), after uniform mixing, add 0.25 part of nano-zinc oxide and 0.5 part of promoting Agent (2-ethyl-4-methylimidazole), stirred until uniform;

[0040](3) In parts by weight, add 50 parts of epoxy resin (cycloaliphatic epoxy resin, type 2021P) to the mixture prepared in the above step (2), mix well and then vacuum degass, pour into the preheated placed in a 120°C oven to cure for 4 hours, and the nano-zinc oxide / a...

Embodiment 2

[0043] This embodiment provides a preparation method of nano-zinc oxide / artemisia annua volatile oil / epoxy resin composite material, comprising the following steps:

[0044] (1) Disperse nano-zinc oxide and γ-aminopropyltriethoxysilane in a mixed solution of water and absolute ethanol at a mass ratio of 20:1, then vacuum-dry at 150°C for 1 hour, and grind after cooling , to obtain nano-zinc oxide after surface treatment;

[0045] (2) In parts by weight, add 0.2 part of Artemisia annua volatile oil to 10 parts of curing agent (dicyandiamide), after uniform mixing, add 0.2 part of nano-zinc oxide prepared in step (1), and stir until uniform;

[0046] (3) In parts by weight, add 89.6 parts of epoxy resin (bisphenol A type epoxy resin, model is E-42) in the mixture that above-mentioned step (2) makes, vacuum degassing after mixing uniformly, cast Put it into a preheated mold, put it in an oven at 30°C and cure it for 8 hours, and then get the nano-zinc oxide / artemisia volatile oi...

Embodiment 3

[0049] This embodiment provides a preparation method of nano-zinc oxide / artemisia annua volatile oil / epoxy resin composite material, comprising the following steps:

[0050] (1) Disperse nano-zinc oxide and γ-methacryloxypropyltrimethoxysilane in a mixed solution of water and absolute ethanol at a mass ratio of 10:1, and then vacuum-dry at 100°C for 3h, Grinding after cooling to obtain surface-treated nano-zinc oxide;

[0051] (2) in parts by weight, add 0.25 part of Artemisia annua volatile oil in 55 parts of curing agent (hexahydrophthalic anhydride), after uniform mixing, add 0.45 part of nano-zinc oxide and 0.3 part of accelerator ( 2,4,6-three (dimethylaminomethyl) phenol), stirred until uniform;

[0052] (3) In parts by weight, add 44 parts of epoxy resin (hydroxymethyl bisphenol A type epoxy resin, model is CEQ-45) in the mixture that above-mentioned step (2) makes, vacuum remove after mixing gas, pour it into a preheated mold, and place it in a 160°C oven for curing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com