Symmetrical layered gradient composite material and preparation method and application thereof

A composite material and gradient technology, applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problem that the ceramic/metal phase interface cannot achieve long-term sealing, etc., and achieve improved material sealing and stability, high mechanical strength , the effect of relieving thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method for preparing the symmetrical layered gradient composite material, the method includes the following steps:

[0036] Step 1, mixing: mix Mo powder, Si 3 N 4 Powder and sintering aids are fully mixed to obtain the required mixture for each layer;

[0037] Step 2, mold loading: stack the mixture required for each layer into the graphite mold in sequence according to the structural design in step 1 and press it into shape, then install the upper and lower graphite indenters sprayed with boron nitride release agent and embed them on the outer surface of the mould. Set of graphite carbon felt;

[0038] Step 3, sintering: place the graphite mold with the sample to be sintered in the spark plasma sintering furnace, complete pre-pressing and vacuuming, then axially pressurize and pass in a DC pulse current to rapidly heat up to the sintering temperature;

[0039]Step 4, mold removal: when the temperature of the sintering system drops to room temperature,...

Embodiment 1

[0052] Weigh an appropriate amount of Si 3 N 4 The powder was milled by a ball mill for 4 hours and then dried in a vacuum oven at 80°C for 12 hours; according to Si 3 N 4 Powder and Mo powder mass percentages are 1:9, 2:8, 3:7, 4:6, 5:5, 6:4, 7:3, 8:2, 9:1, respectively weigh raw materials, After ball milling with a ball mill for 2 hours, put it into a vacuum drying oven at 80° C. for 12 hours.

[0053] The ball milling process is as follows: put the raw material powder into a 125ml nylon ball milling tank, according to powder: alcohol: ZrO 2 The ratio of balls=1:1:4 is used for ball milling. The model of the ball mill used is Retsch PM100, and the speed of the ball mill is set at 300 rpm to obtain a mixed powder with a particle size of 0.5-2 μm.

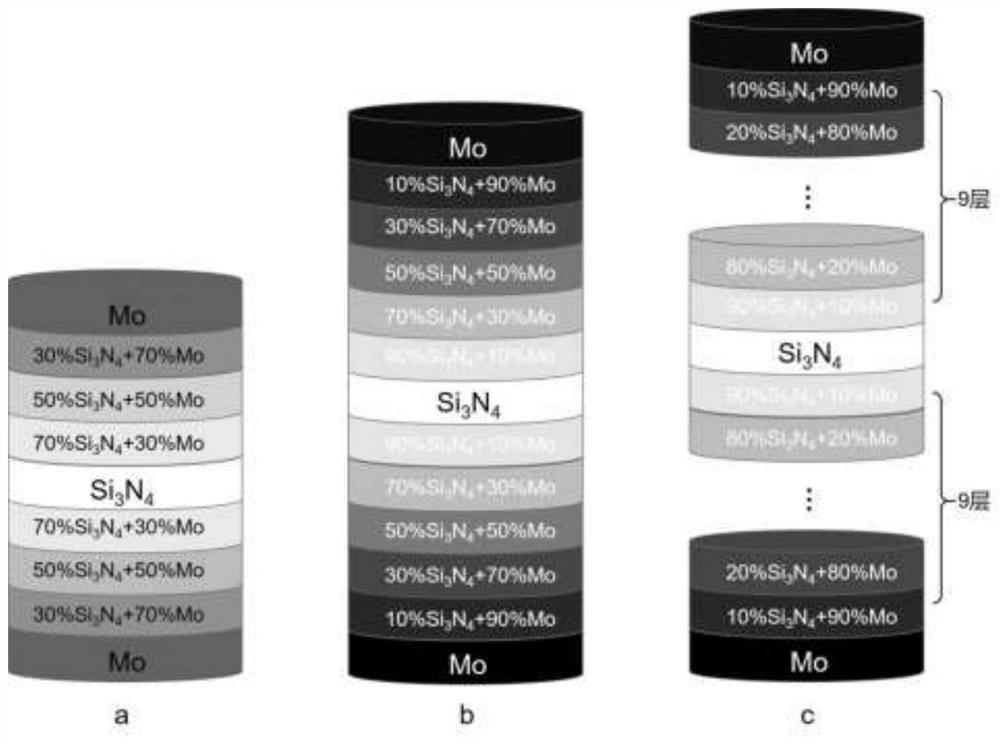

[0054] Mix the powder according to the figure 1 The schematic diagram of the structure shown in c is laid layer by layer into a graphite mold with an inner diameter of 25mm. The amount of the middle ceramic layer is 2g, the am...

Embodiment 2

[0057] Weigh an appropriate amount of Si 3 N 4 The powder was milled by a ball mill for 4 hours and then dried in a vacuum oven at 80°C for 12 hours; according to Si 3 N 4 Powder and Mo powder mass percentages are 1:9, 3:7, 5:5, 7:3, 9:1, respectively weigh the raw materials, use a ball mill for 2 hours, and then put them in a vacuum oven at 80°C for 12 hours. .

[0058] The ball milling process is as follows: put the raw material powder into a 125ml nylon ball milling tank, according to powder: alcohol: ZrO 2 The ratio of balls=1:1:4 is used for ball milling. The model of the ball mill used is Retsch PM100, and the speed of the ball mill is set at 300 rpm to obtain a mixed powder with a particle size of 0.5-2 μm.

[0059] Mix the powder according to the figure 1 The schematic diagram of the structure shown in b is laid layer by layer into a graphite mold with an inner diameter of 25mm. The amount of the middle ceramic layer is 2g, the amount of each gradient layer is 1g,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com