A kind of composite catalytic filter material for degrading dioxin at low temperature and preparation method thereof

A technology of high temperature resistant filter material and filter material, which can be used in catalyst activation/preparation, chemical instruments and methods, separation methods, etc. Has the effect of performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

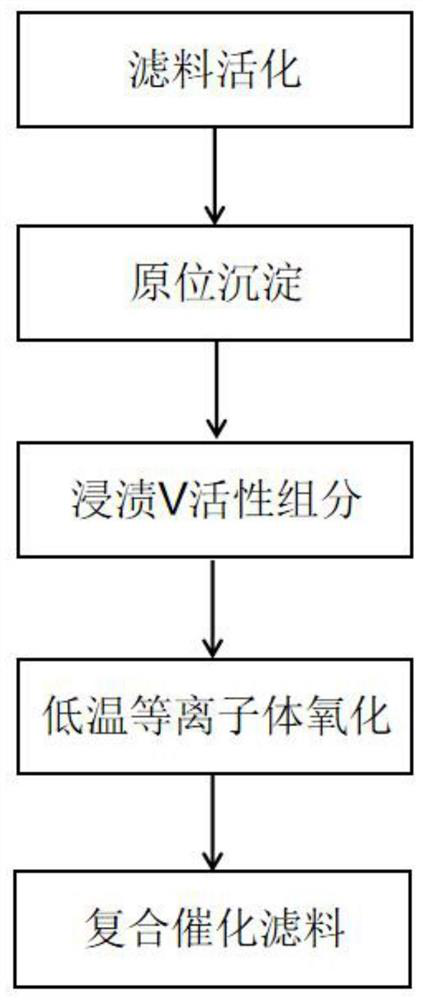

[0034] Such as figure 1 Shown, preparation method of the present invention is as follows:

[0035] (1) Filter material activation: First cut out a polyphenylene sulfide needle felt filter material disc with a diameter of 20mm, wash it three times with deionized water, dry it in an oven at 105°C for 6 hours, and weigh it; weigh 0.0577g Sodium lauryl sulfate powder was prepared into 200 mL of 0.001 mol / L sodium lauryl sulfate solution with deionized water as a solvent, and the dried polyphenylene sulfide disc was immersed in the solution, and ultrasonically activated for 1 h.

[0036] (2) Precipitation in situ: a). Impregnating Ce active components: Weigh 0.3251 g of cerium chloride heptahydrate and add it to the solution obtained in step (1), and stir at room temperature for 12 hours.

[0037] b).KMnO 4 Oxidation: Weigh 1.3790g of potassium permanganate powder, dissolve it in 100mL of deionized water, and prepare a 0.08mol / L potassium permanganate solution, and add 100mL of 0...

Embodiment 2

[0041] (1) Filter material activation: first cut out a polyphenylene sulfide needle felt filter material disc with a diameter of 20mm, wash it three times with deionized water, dry it in an oven at 105°C for 6 hours, and weigh it; weigh 0.2307g Sodium lauryl sulfate powder was prepared into 200 mL of 0.004 mol / L sodium lauryl sulfate solution with deionized water as a solvent, and the dried polyphenylene sulfide disc was immersed in the solution, and ultrasonically activated for 2 hours.

[0042] (2) Precipitation in situ: a): impregnation of Ce active components: Weigh 0.6502 g of cerium chloride heptahydrate and add it to the solution obtained in step (1), and stir at room temperature for 16 hours.

[0043] b): KMnO 4 Oxidation: Weigh 2.7580g of potassium permanganate powder, dissolve it in 100mL of deionized water, and prepare a 0.17mol / L potassium permanganate solution, and add 100mL of 0.17mol / L potassium permanganate solution to step a ) in the resulting solution, stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com