Dental implant and dental implant manufacturing method

A technology for dental implants and implants, which is applied in the fields of dental implants, dentistry, and dental repairs, etc., can solve the problems of large stress shielding and poor osseointegration of dental implants, and achieve small stress shielding and solve osseointegration performance Poor, the effect of improving osseointegration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

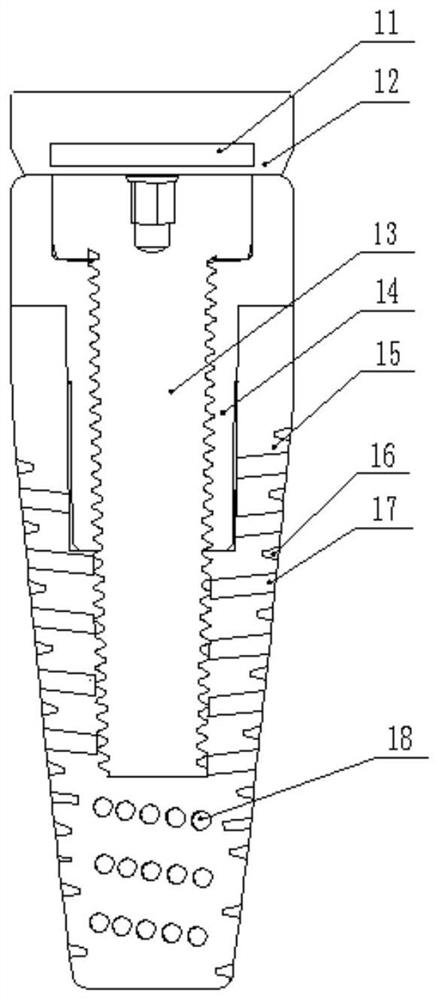

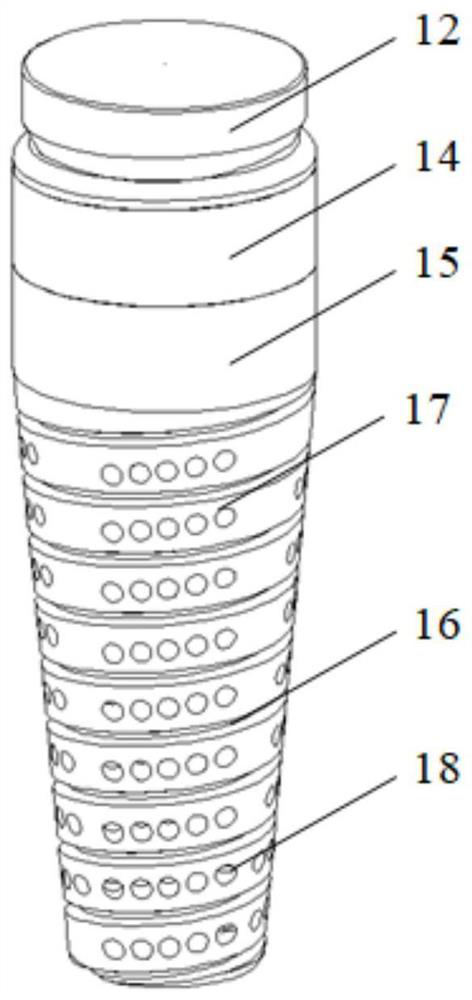

[0039] see Figure 1 to Figure 4 , In one embodiment, a dental implant includes an implant 15 , a fixing screw 13 , a fixing abutment 14 , and a treatment cap 12 .

[0040] Wherein, the implant body 15 includes an end portion and a cone portion. The upper end of the cone part is connected with the lower end of the end part. The diameter of the lower base of the cone is smaller than the diameter of the upper base. The outer surface of the cone is provided with an external thread 16 . The external thread 16 is respectively provided with a first pore area 17 and a second pore area 18 from bottom to top. Several first pores are opened in the first pore area 17 , and second pores are opened in the second pore area 18 . Wherein, the first hole is a through hole, and the second hole is a blind hole.

[0041] An accommodating space is opened at the upper end of the implant body 15 formed by the cooperation of the end portion and the taper portion. The lower end of the fixed base...

Embodiment 2

[0054] A method for manufacturing a dental implant, used to manufacture the dental implant in the first embodiment, the specific steps are as follows:

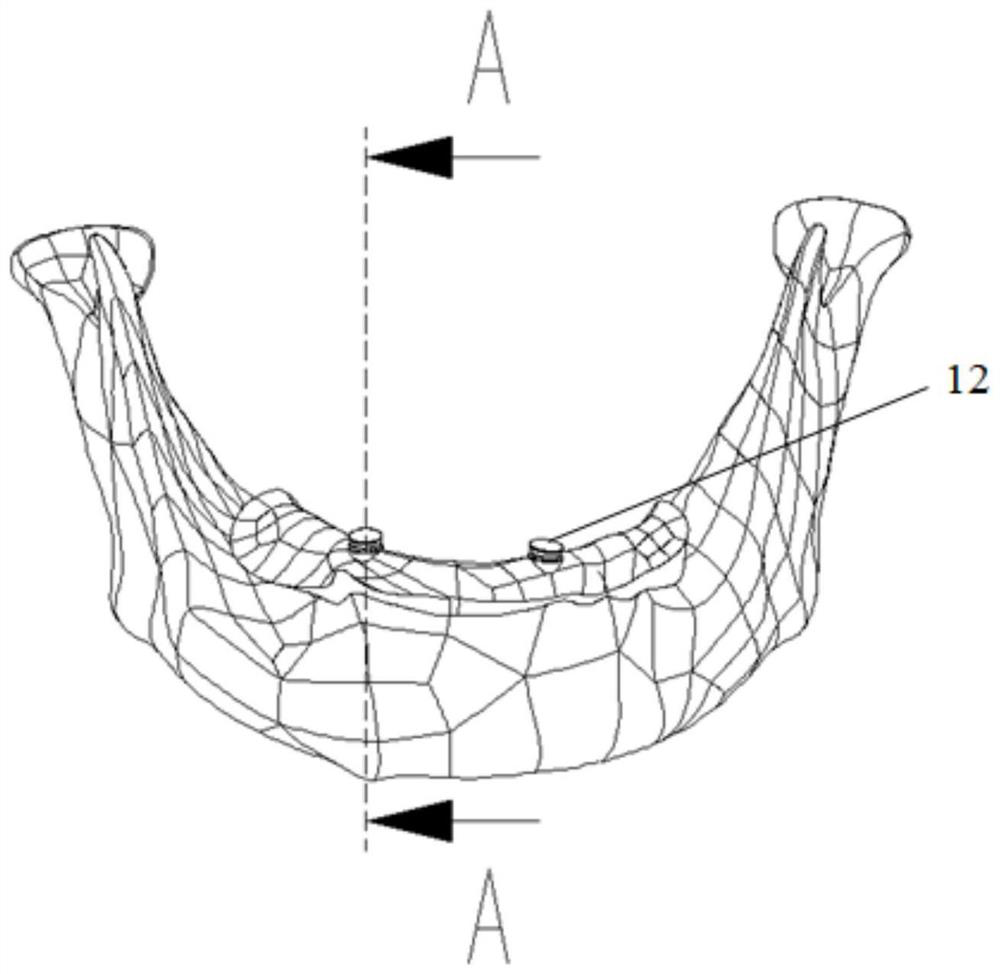

[0055] S1: Use the DICOM modeling method, use CT technology to photograph the edentulous mandible, obtain the corresponding CT data, and use the medical image software Minics, reverse engineering software Geomagic and 3D design software SolidWorks to establish a model including the edentulous mandible, mucosa and the first 3D finite element model of the denture. The purpose of constructing this model is to simulate the actual application effect of dental implants in real implant situations;

[0056] S2: Through the drawing of the dental implant, each part of the three-dimensional model of the dental implant is established in SolidWorks, and assembled to form a second three-dimensional finite element model of the dental implant.

[0057] S201: Carry out detail processing on the implant 15, draw a helix along the slope from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com