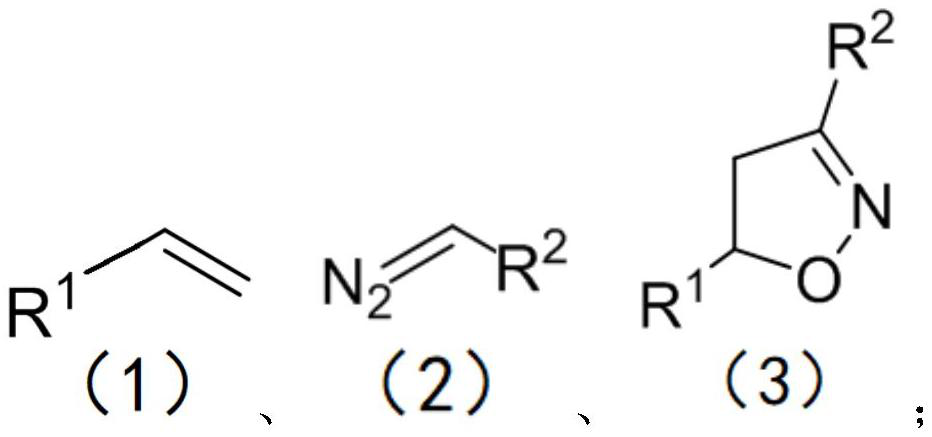

Method for preparing isoxazoline

An isoxazoline and a selected technology, applied in the field of preparing isoxazoline, can solve problems such as limited application, and achieve the effects of good reaction, cheap and easily available raw materials, and convenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

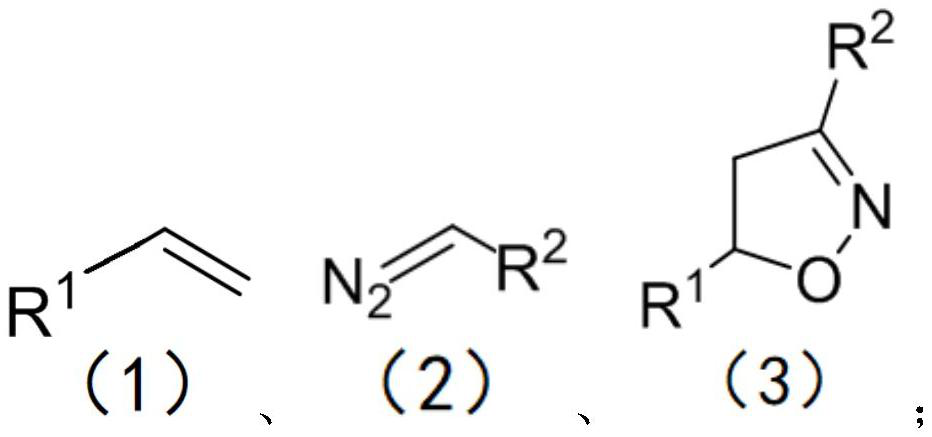

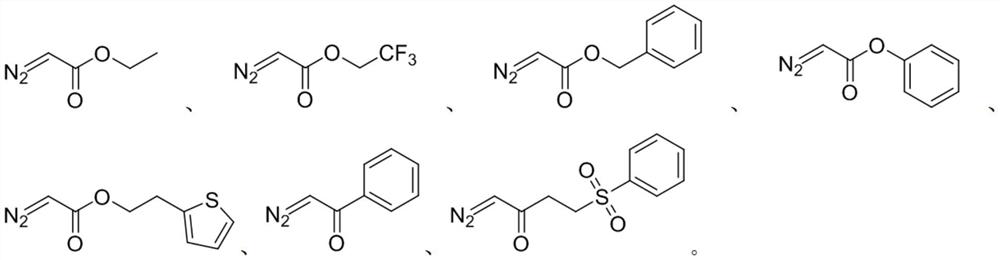

Method used

Image

Examples

Embodiment 1

[0040]

[0041] Add acetonitrile (40mL), compound 1a (10mmol, 1.78g), compound 2a (20mmol, 2.40g), compound 3 (20mmol, 2.17g), catalyst boron trifluoride diethyl ether (1mmol, 263μL) into the reaction flask in sequence; Then react under the condition of 25 ℃ in the air for 12 hours; The mixed solvent of petroleum ether was subjected to column chromatography to obtain the product 4a with a yield of 80%. The main test data of the obtained product are as follows. It can be seen from the analysis that the actual synthesized product is consistent with the theoretical analysis.

[0042] 1 H NMR (400MHz, CDCl 3 )δ7.40(d, J=8.4Hz, 2H), 7.26(d, J=8.4Hz, 2H), 5.76(dd, J=11.6, 9.0Hz, 1H), 4.36(q, J=7.1Hz, 2H), 3.60(dd, J=17.8, 11.6Hz, 1H), 3.23(dd, J=17.8, 9.0Hz, 1H), 1.37(t, J=7.1Hz, 3H), 1.31(s, 9H). ; 13 C NMR (101MHz, CDCl 3 )δ160.5, 151.7, 151.1, 136.3, 125.69, 125.66, 84.9, 62.0, 41.1, 34.5, 31.2, 14.0; HRMS (ESI-TOF): Anal. Calcd. For C 16 h 21 NO 3 +H + :276.1594,Fou...

Embodiment 2

[0044]

[0045]Add acetonitrile (2.0mL), compound 1b (0.5mmol, 53.2mg), compound 2a (1.0mmol, 108μL), compound 3 (1.0mmol, 121μL), catalyst boron trifluoride diethyl ether (0.05mmol , 14 μL); then reacted for 12 hours at 25°C in the air; after the reaction was completed, it was quenched with saturated sodium chloride solution, extracted with ethyl acetate, the solvent was removed by a rotary evaporator, adsorbed on silica gel, and finally used The mixed solvent of ethyl acetate and petroleum ether was subjected to column chromatography to obtain the product 4b with a yield of 74%. The main test data of the obtained product are as follows. It can be seen from the analysis that the actual synthesized product is consistent with the theoretical analysis.

[0046] 1 H NMR (400MHz, CDCl 3 )δ7.47-7.21(m,5H),5.77(dd,J=11.6,8.9Hz,1H),4.35(q,J=7.1Hz,2H),3.63(dd,J=17.8,11.6Hz,1H ),3.21(dd,J=17.8,8.9Hz,1H),1.37(t,J=7.1Hz,3H).; 13 C NMR (101MHz, CDCl 3 )δ160.4, 151.0, 139.4, 128.7,...

Embodiment 3

[0048]

[0049] Add acetonitrile (2.0mL), compound 1c (0.5mmol, 61.1mg), compound 2a (1.0mmol, 108μL), compound 3 (1.0mmol, 121μL), catalyst boron trifluoride diethyl ether (0.05mmol , 14 μL); then reacted for 12 hours at 25°C in the air; after the reaction was completed, it was quenched with saturated sodium chloride solution, extracted with ethyl acetate, the solvent was removed by a rotary evaporator, adsorbed on silica gel, and finally used The mixed solvent of ethyl acetate and petroleum ether was subjected to column chromatography to obtain the product 4c with a yield of 67%. The main test data of the obtained product are as follows. It can be seen from the analysis that the actual synthesized product is consistent with the theoretical analysis.

[0050] 1 H NMR (400MHz, CDCl 3 )δ7.35-7.28(m,2H),7.14-7.00(m,2H),5.77(dd,J=11.6,8.9Hz,1H),4.36(q,J=7.1Hz,2H),3.64(dd ,J=17.8,11.6Hz,1H),3.18(dd,J=17.8,8.9Hz,1H),1.38(t,J=7.1Hz,3H); 13 C NMR (101MHz, CDCl 3 )δ162.7(d, J=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com