A preparation method of silicon carbide nanowire reinforced silicon carbide ceramic composite material with high strength and high toughness

A technology of silicon carbide nanowires and silicon carbide ceramics is applied in the field of silicon carbide ceramic matrix composite materials, which can solve the problem of high bonding strength and achieve the effect of increasing dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

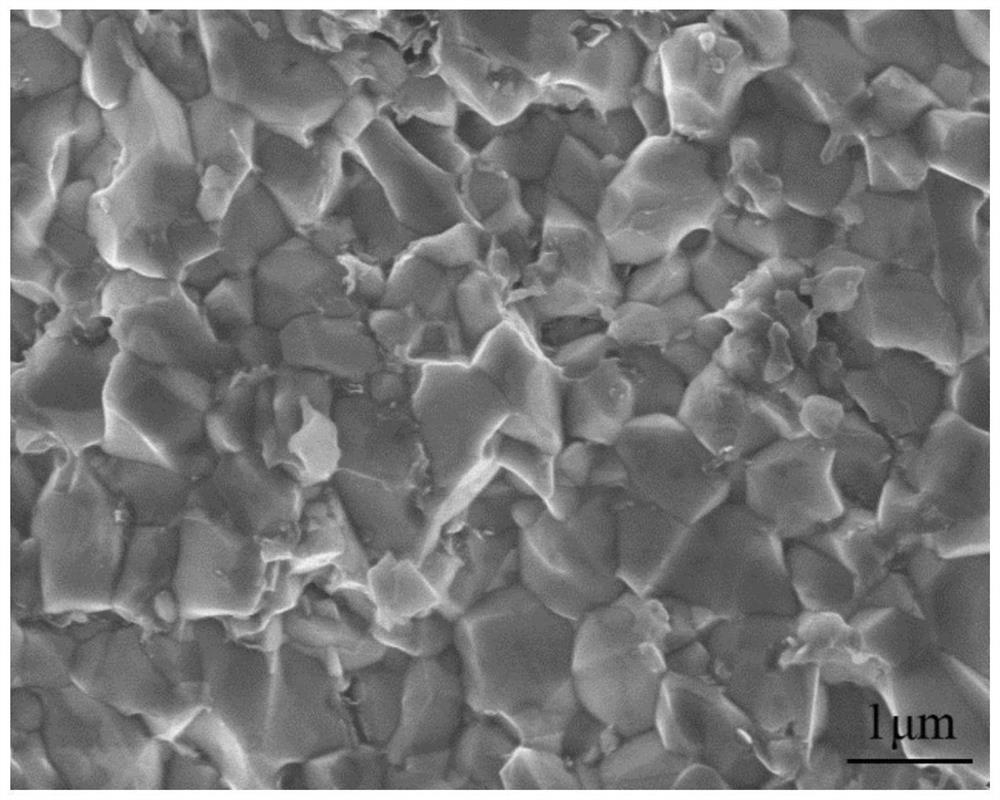

Image

Examples

Embodiment 1

[0052] (1) Add 1g of silicon carbide nanowires and 1mL of 3-aminopropyl-triethoxysilane into 150mL of toluene, heat to reflux and continue to stir for 6h, then filter with suction and dry at 60°C for 2h to obtain dry Modified silicon carbide nanowires.

[0053] (2) Evenly disperse 0.1g of modified silicon carbide nanowires, 0.2g of resorcinol and 97mL of formaldehyde in a solution consisting of 80mL of deionized water, 32mL of absolute ethanol and 0.4mL of ammonia water, and use magnetic stirring for 24h , and then suction filtered and freeze-dried for 12 hours to obtain silicon carbide nanowires coated with phenolic resin coating.

[0054] (3) the silicon carbide nanowire coated with phenolic resin coating obtained in step (2) is raised to 350° C. with a heating rate of 2° C. / min in a horizontal tube furnace with helium as the protective gas, Then keep it warm for 2 hours, then raise it to 650° C. at 2° C. / min, keep it warm for 2 hours, and then lower the temperature natural...

Embodiment 2

[0060] According to Example 1, steps (1), (3), and (5) of this example are the same as Example 1, and the quality of Resorcinol in Step (2) of Example 1 is changed to 0.3g, and the volume of formaldehyde is changed to 145mL, change the net content of silicon carbide nanowires in the composite ceramic powder in step (4) of Example 1 to 7wt.%, change the carbon content to 3.76wt.%, and the rest are the same as in Example 1, and the obtained composite ceramic The block is a disc-shaped block with a diameter of 10 mm and a thickness of about 1 mm. The MSP strength measured by the MSP test method is 901 MPa; and the fracture toughness is calculated by the indentation of the Vickers hardness tester on the polished surface of the composite ceramic sample. 5.01MPa·m 1 / 2 .

[0061] image 3 It shows that: in the transmission electron microscope image of the silicon carbide nanowire coated with carbon coating in this embodiment, the carbon coating is evenly coated on the surface of th...

Embodiment 3

[0064] Step (1) is identical with embodiment 1 step (1).

[0065] (2) Evenly disperse 0.1g of modified silicon carbide nanowires, 0.4g of resorcinol and 193mL of formaldehyde in a solution consisting of 80mL of deionized water, 32mL of absolute ethanol and 0.4mL of ammonia water, and use magnetic stirring for 24h , and then suction filtered and freeze-dried for 12 hours to obtain silicon carbide nanowires coated with phenolic resin coating.

[0066] Step (3) is identical with embodiment 1 step (3).

[0067] (4) After measuring the carbon content (wt.%) and the content of silicon carbide nanowires in the carbon coating-coated silicon carbide nanowires in step (3) by thermogravimetric analysis, design the silicon carbide ceramic powder for each Component specific gravity, make the net content of silicon carbide nanowire in composite ceramic powder body be 7wt.%, carbon content is 5.28wt.%, sintering aid is aluminum oxide and boron carbide, and its total mass ratio is 10wt.% (al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com