A kind of phenolic resin carbon microsphere and its preparation method and application

A technology of phenolic resin and carbon microspheres, which is applied in the preparation/purification of carbon, structural parts, electrical components, etc., can solve problems such as the inability to carry out surface structure, complex preparation methods, smooth surface of carbon microspheres, etc., to achieve spherical Controllable diameter and specific surface area, simple process, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The present invention provides a kind of preparation method of described phenolic resin carbon microsphere, at least comprises the following steps:

[0018] 1) dissolving the thermoplastic phenolic resin in an alkaline solution to obtain system I;

[0019] 2) Add phenol, aldehyde, and catalyst into the reaction kettle, and obtain system II after heating and reacting;

[0020] 3) Mixing system I and system II evenly, adjusting the pH of the system to 6.5-10.5, heating and reacting, and then separating and drying to obtain phenolic resin microspheres.

[0021] 4) Carbon microspheres were obtained after carbonization of phenolic resin microspheres.

[0022] The main mechanism of this method is that the main component in alkaline solution is linear long-chain phenolic resin, which has good solubility and stability in alkaline solution, and the main component in acidic solution is low molecular resin and unreacted phenol and aldehyde , when the acidic solution is mixed wit...

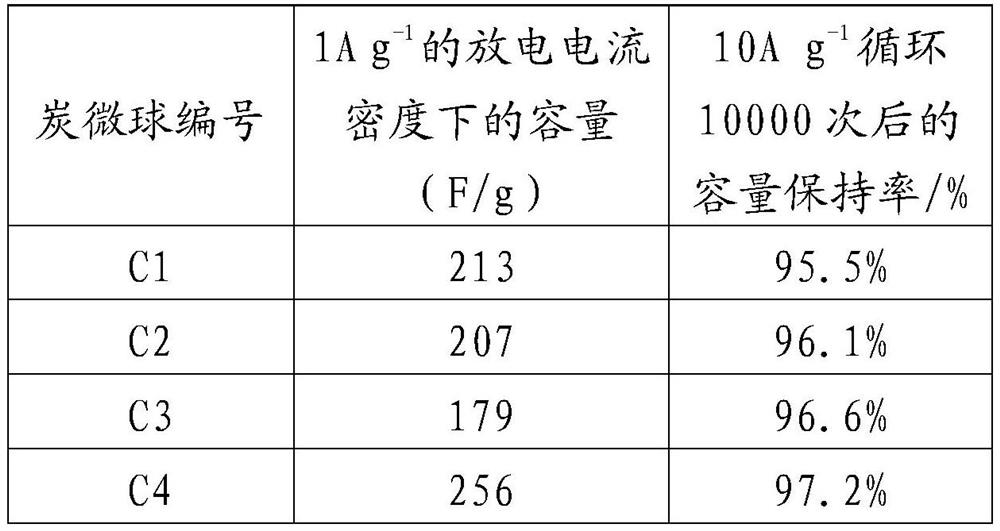

Embodiment 1

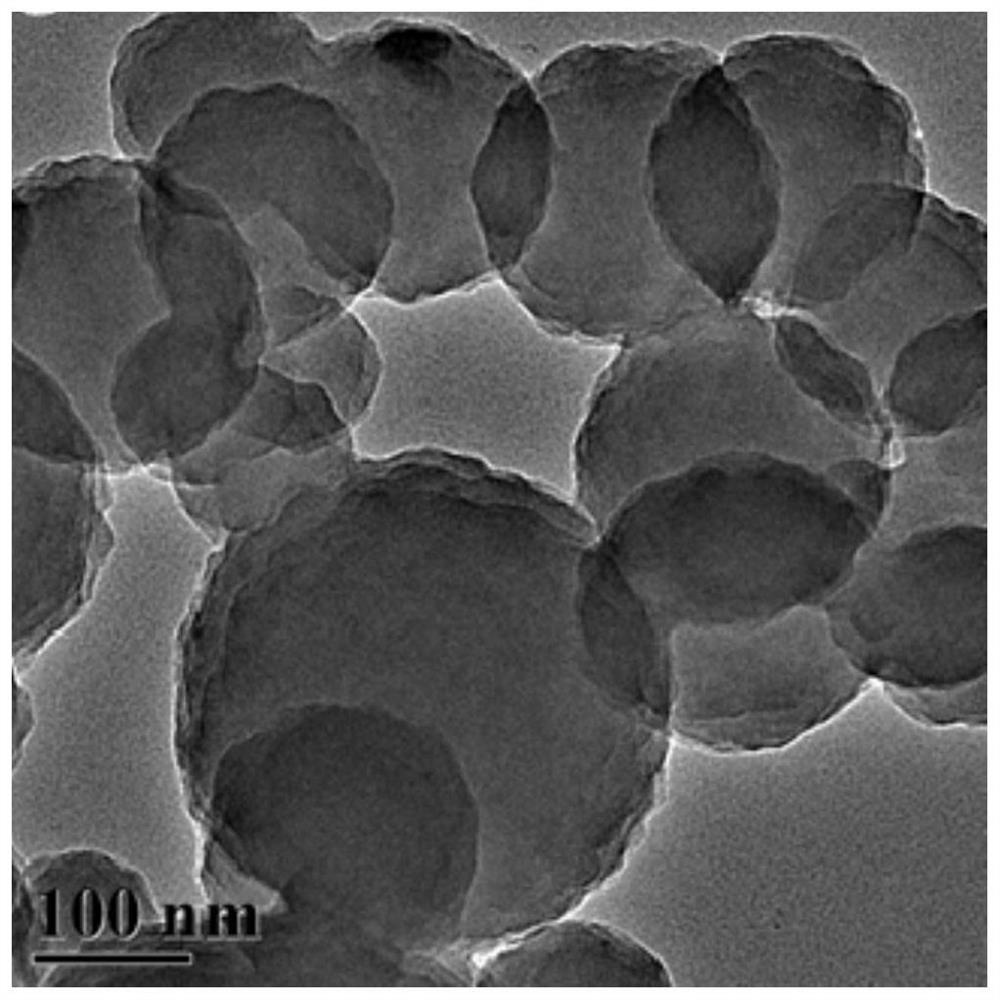

[0042] Dissolve 2 g of thermoplastic phenol-formaldehyde resin in 100 ml of aqueous sodium hydroxide solution to obtain System I; add 0.2 g of phenol, 0.53 g of formaldehyde solution, and 0.001 g of oxalic acid into the reactor, heat to 80°C for 30 minutes, and obtain System II; combine System I with Mix the system II evenly, adjust the pH of the system to 10, heat to 100°C for 24 hours; use a 5000r / min centrifuge to separate for 5 minutes, and then put it in a 120°C oven to dry to obtain phenolic resin microspheres; put the above phenolic resin microspheres in Under nitrogen atmosphere, carbonize at 650° C. for 4 hours to obtain the phenolic resin carbon microspheres C1. The prepared phenolic resin carbon microspheres have a particle size of 173nm and a surface specific surface area of 56m 2 / g, carbon content is 89.3%, BET specific surface area is 657m 2 / g, the pore volume is 0.25cm 3 / g, the average pore size is 5.6nm, please refer to figure 1 .

[0043] Wherein, the...

Embodiment 2

[0045] Dissolve 2 g of thermoplastic phenol-formaldehyde resin in 50 ml of aqueous sodium hydroxide solution to obtain system I; add 0.2 g of phenol, 0.53 g of formaldehyde solution, and 0.001 g of oxalic acid into the reactor, heat to 80°C for 30 minutes to obtain system II; combine system I with Mix the system II evenly, adjust the pH of the system to 10, heat to 100°C for 24 hours; use a 5000r / min centrifuge to separate for 5 minutes, and then put it in a 120°C oven to dry to obtain phenolic resin microspheres; put the above phenolic resin microspheres in Under nitrogen atmosphere, carbonize at 650°C for 4 hours to obtain the phenolic resin carbon microspheres C2. The prepared phenolic resin carbon microspheres have a particle size of 253nm and a surface specific surface area of 51m 2 / g, the carbon content is 91.1%, and the BET specific surface area is 552m 2 / g, the pore volume is 0.23cm 3 / g, the average pore diameter is 7nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com