A flash welding method for hrb600 high-strength hot-rolled steel bar

A welding method and steel bar technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of long welding process, high alloy addition, low strength level, etc., and achieve high strength, high toughness and reliability of welded joints. Safety, saving welding time, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Flash butt welding of ∮20mm specification HRB600 steel bar:

[0034] The main components of the HRB600 steel bar are C 0.25, Si 0.62, Mn 1.55, V 0.15, Ceq=0.52.

[0035] (1) Pretreatment before welding: Grinding the end face of the steel bar to be welded to remove rust and scale to ensure its smoothness;

[0036] (2) Clamping of steel bars to be welded: Clamp the two ends of the steel bars to be welded in the electrode chuck and pass through the induction coil to ensure that the transverse ribs of the steel bars to be welded are penetrated and the longitudinal ribs are relatively parallel. Upsetting length 25mm.

[0037] (3) Flash welding process setting: induction heating temperature 980°C, induction heating time 15s, flash heat 75kJ, flash distance 16mm, flash speed 1.5mm / s, upsetting air pressure 0.75MPa, upsetting time ≤ 1s, pressure maintenance time 15s.

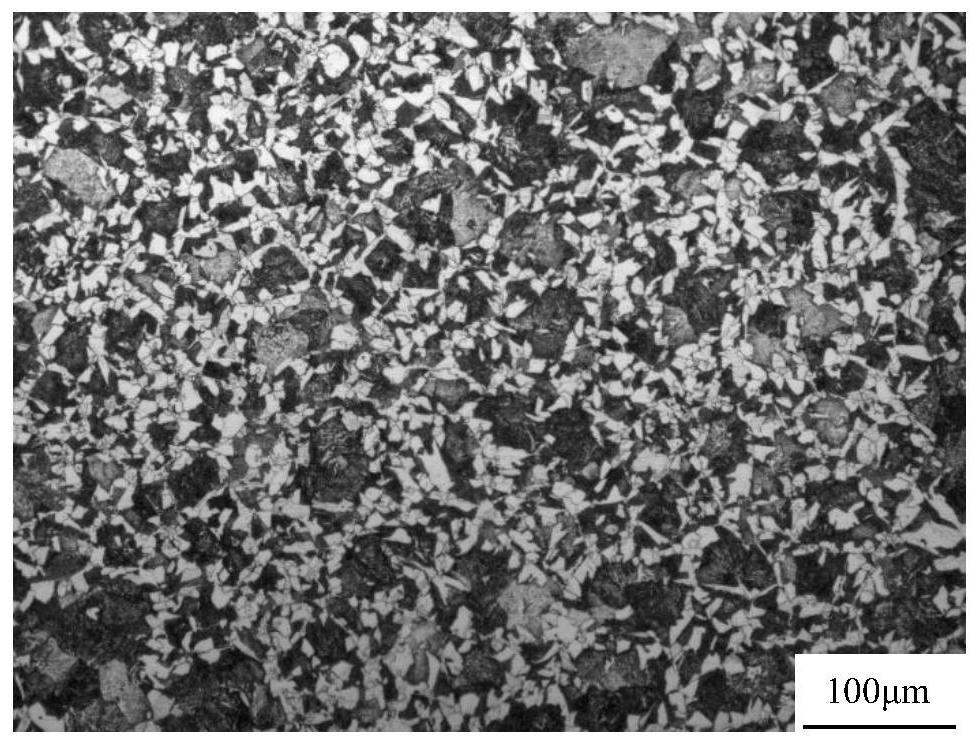

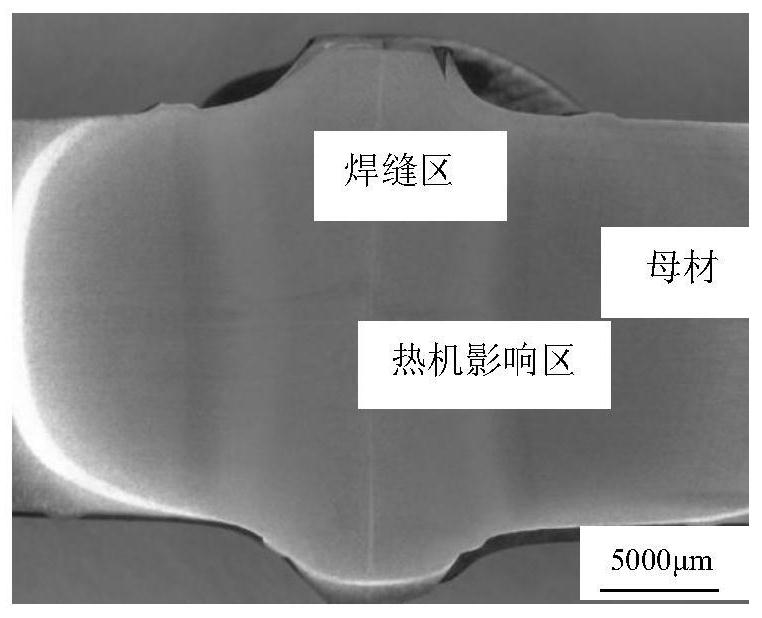

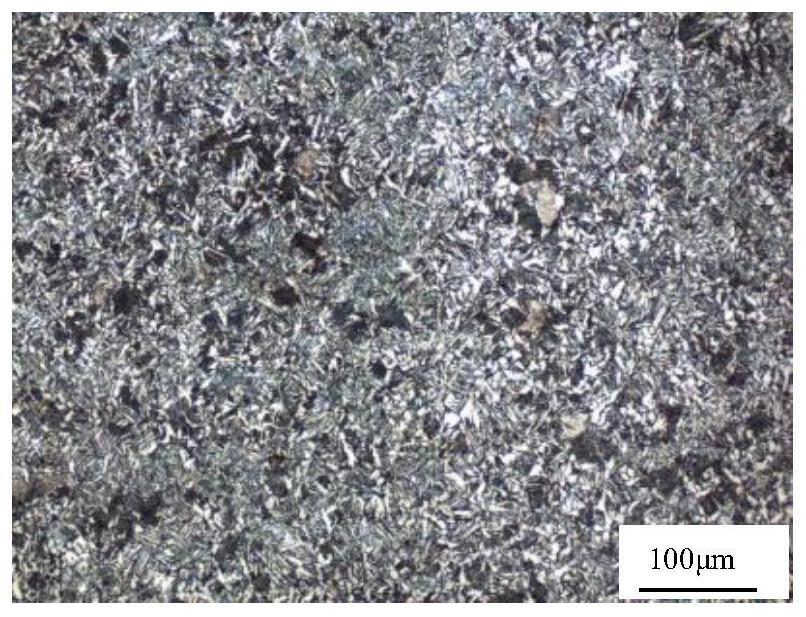

[0038] (4) Turn on the power and start the program, and the steel bars to be welded are subjected to induct...

Embodiment 2

[0044] Flash butt welding of ∮28mm HRB600 steel bars:

[0045] The main components of the HRB600 steel bar are C 0.27, Si 0.71, Mn 1.35, V 0.18, Ceq=0.53.

[0046] (1) Pre-welding pretreatment: grinding the end face of the steel bar to be welded to remove rust and oxide skin to ensure its smoothness and smoothness;

[0047] (2) Clamping of the steel bars to be welded: Clamp the two ends of the steel bars to be welded in the electrode chuck and pass through the induction coil to ensure that the transverse ribs of the steel bars to be welded pass through and the longitudinal ribs are relatively parallel. Upset forging length 40mm.

[0048] (3) Flash welding process settings: induction heating temperature 1040℃, induction heating time 22s, flash heat 120kJ, flash distance 30mm, flash speed 0.2mm / s, upsetting pressure 1.25MPa, upsetting time ≤1.5s, pressure maintained Time 30s.

[0049] (4) Turn on the power supply and start the program, and the steel bars to be welded undergo ...

Embodiment 3

[0055] Flash butt welding of ∮12mm HRB600 steel bars:

[0056] The main components of the HRB600 steel bar are C 0.24, Si 0.57, Mn 1.40, V 0.14, and Ceq=0.50.

[0057] (1) Pre-welding pretreatment: grinding the end face of the steel bar to be welded to remove rust and oxide skin to ensure its smoothness and smoothness;

[0058] (2) Clamping of the steel bar to be welded: Clamp the two ends of the steel bar to be welded in the electrode chuck and pass through the induction coil to ensure that the transverse ribs of the steel bar to be welded pass through and the longitudinal ribs are relatively parallel. Upset forging length 15mm.

[0059] (3) Flash welding process settings: induction heating temperature 920℃, induction heating time 6s, flash heat 40kJ, flash distance 8mm, flash speed 2.0mm / s, upsetting pressure 0.35MPa, upsetting time ≤ 0.5s, pressure maintained Time 5s.

[0060] (4) Turn on the power supply and start the program, and the steel bars to be welded undergo the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com