Small-particle-size large-plate ceramic tile binder and preparation method thereof

A technology of small particle size and binder, which is applied in the field of chemical building materials, can solve the problems of poor coating effect, large latex particle size, and adhesion force that cannot meet the requirements of large bricks, and achieve fast drying time and film formation High mechanical strength and the effect of improving the firmness coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

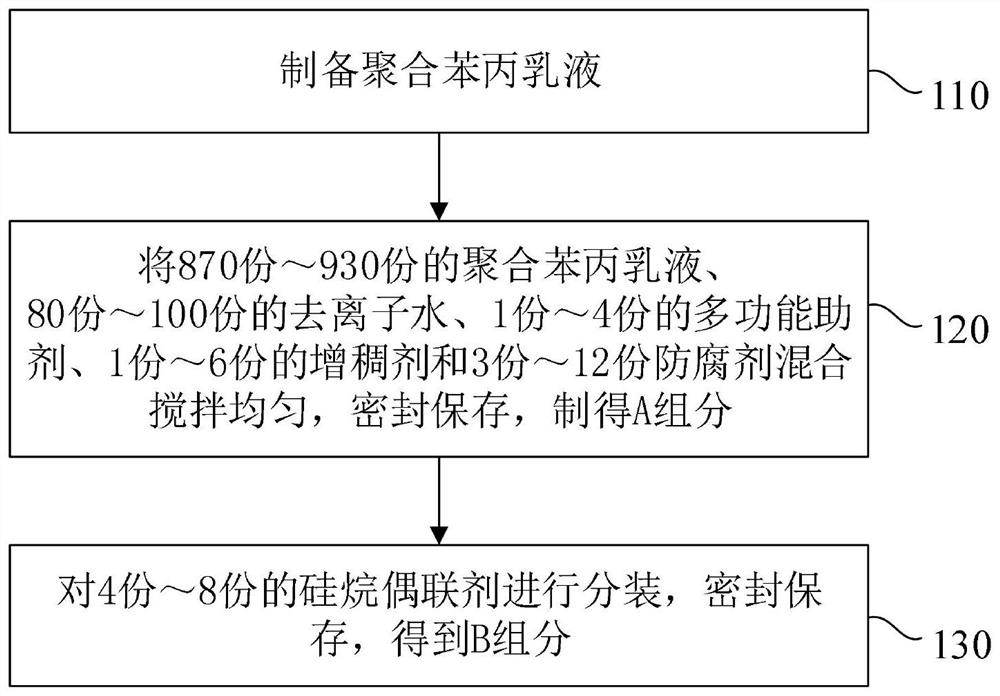

[0044] like figure 1 Shown, in one embodiment, the preparation method of described small particle size large-slab brick adhesive in the above-mentioned embodiment is provided, a kind of preparation method of small particle size large-slab brick adhesive comprises the following steps:

[0045] Step 110, preparing polymerized styrene-acrylic emulsion.

[0046] Specifically, each component is weighed according to the weight of the desired polymerized styrene-acrylic emulsion, and then the weighed pure water, the styrene, the acrylic acid, the butyl acrylate, the methyl methacrylate Esters and the hydroxyethyl methacrylate are put into the In the polymerization reactor, heat while stirring, add emulsifier for pre-emulsification, the emulsifier is ammonium oleate, potassium oleate, ammonium stearate, potassium stearate, triethanolammonium oleate, polyoxyethylene alkanes any one or any combination of polyoxyethylene alkylaryl esters, sodium dodecylbenzenesulfonate, sodium lauryl s...

Embodiment 1

[0056]Said pure water, said styrene, said acrylic acid, said butyl acrylate, said methyl methacrylate and said hydroxyethyl methacrylate according to 33%, 10%, 0.5%, 20%, The ratio of 15% and 1.5% is put into the polymerization reaction kettle, heated while stirring, and the emulsifier is added for pre-emulsification, and then the initiator, buffer and activator are added to the pre-emulsion for polymerization reaction to obtain a copolymer , and finally the copolymer is cooled and filtered to obtain a polymerized styrene-acrylic emulsion with a fine particle size.

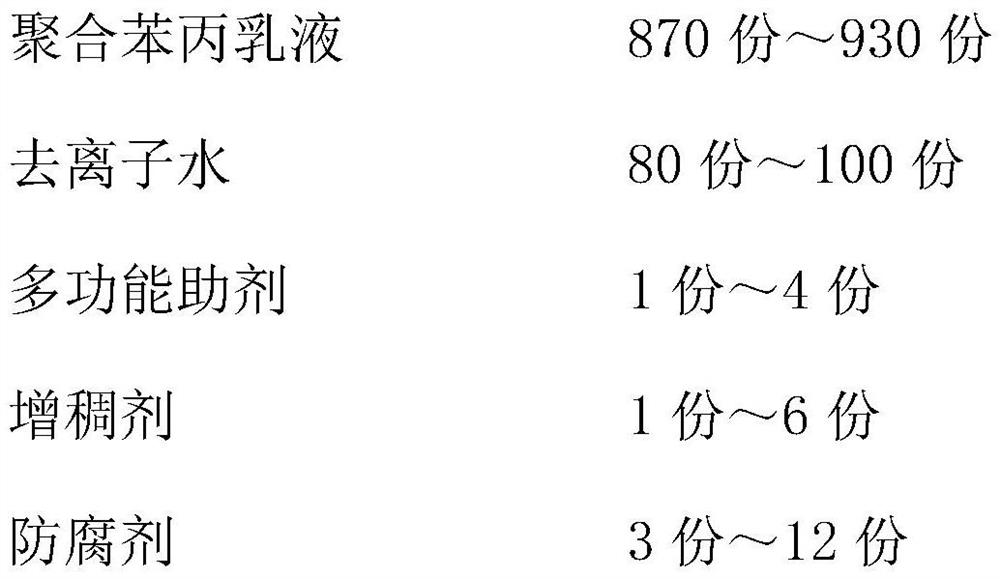

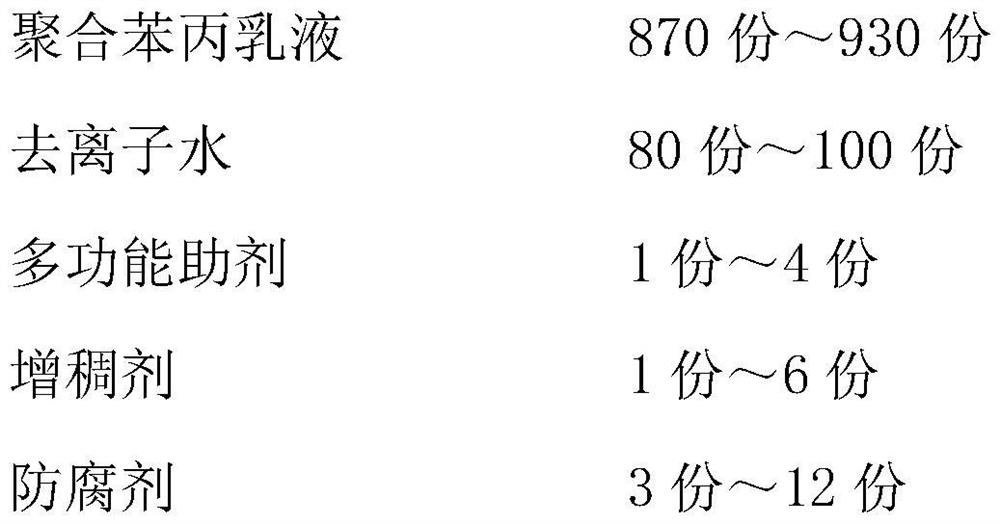

[0057] The obtained 870 parts of polymerized styrene-acrylic emulsion, 80 parts of deionized water, 1 part of multifunctional additive, 1 part of thickener and 3 parts of preservative were mixed and stirred evenly, sealed and preserved to obtain component A. 4 parts of silane coupling agent are subpackaged, sealed and stored to obtain component B, and mixed according to the weight ratio between component A and com...

Embodiment 2

[0060] Said pure water, said styrene, said acrylic acid, said butyl acrylate, said methyl methacrylate and said hydroxyethyl methacrylate according to 53%, 15%, 2%, 25%, The proportions of 20% and 5% are put into the polymerization reactor, heated while stirring, adding an emulsifier for pre-emulsification, and then adding initiator, buffer and activator to the pre-emulsion for polymerization to obtain a copolymer , and finally the copolymer is cooled and filtered to obtain a polymerized styrene-acrylic emulsion with a fine particle size.

[0061] 930 parts of polymerized styrene-acrylic emulsions obtained, 100 parts of deionized water, 4 parts of multifunctional additives, 6 parts of thickeners and 12 parts of preservatives, 20 parts of modified epoxy resins by weight, mixed Stir evenly, seal and preserve, and make A component, described modified epoxy resin comprises: bisphenol A type epoxy resin, unsaturated polyester resin and polyphenylene sulfide, and the weight ratio ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulling force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com