PU high-definition transparent primer and preparation method thereof

A transparent primer, high-definition technology, used in primers, coatings, fire-retardant coatings, etc., can solve problems such as low production efficiency and easy to get prickly heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

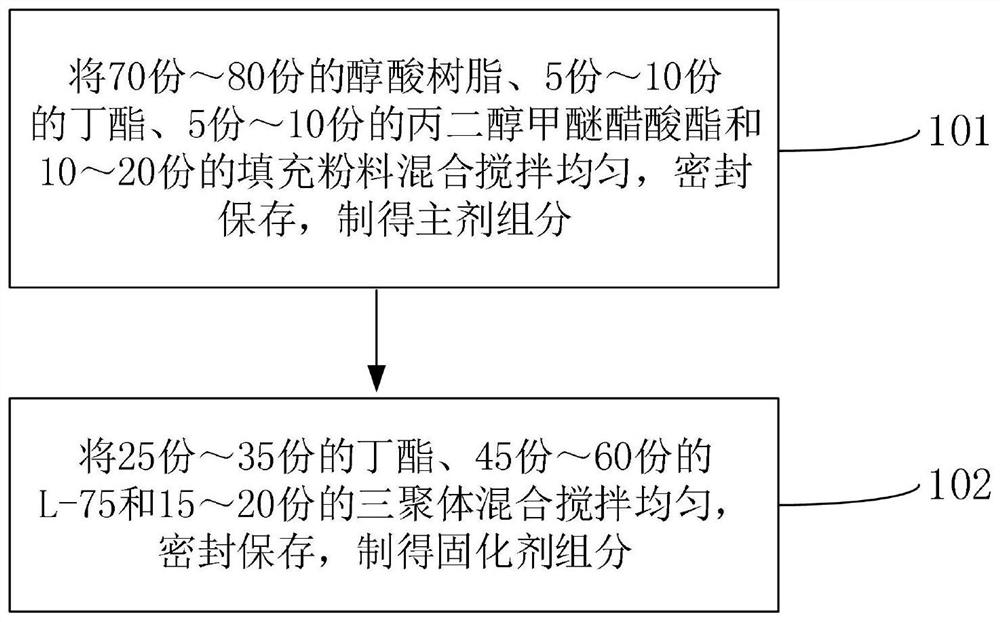

[0049] like figure 1 As shown, in one embodiment, the preparation method of the described PU high-definition transparent primer in the above-mentioned embodiment is provided, a kind of preparation method of PU high-definition transparent primer, comprising:

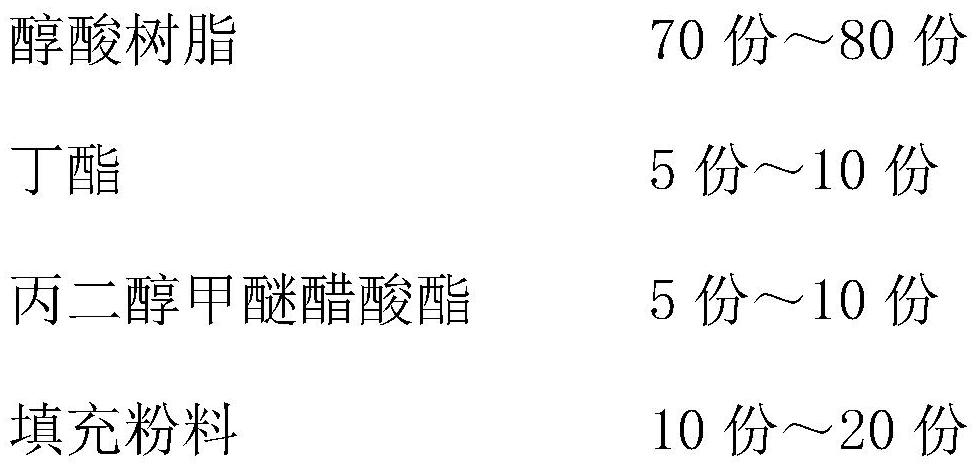

[0050] Step 101. Mix 70 to 80 parts of alkyd resin, 5 to 10 parts of butyl ester, 5 to 10 parts of propylene glycol methyl ether acetate, and 10 to 20 parts of filling powder, mix and stir evenly, and store in a sealed container , to obtain the main agent components.

[0051] Specifically, 70 to 80 parts of alkyd resin, 5 to 10 parts of butyl ester, 5 to 10 parts of propylene glycol methyl ether acetate and 10 to 20 parts of filler powder are mixed and stirred evenly, It is sealed and stored. When preparing the main ingredients, use a planetary mixer, under the conditions of a vacuum degree of -0.04 to -0.10MPa and a rotation speed of 30 to 40r / min, 70 to 80 parts of alkyd resin, 5 parts to 10 parts of butyl ester, 5 pa...

Embodiment 1

[0056] Mix 70 parts of alkyd resin, 5 parts of butyl ester, 5 parts of propylene glycol methyl ether acetate and 10 parts of filling powder, mix and stir evenly, seal and store to prepare the main ingredient components; mix 25 parts of butyl ester, 45 parts of Parts of L-75 and 15 parts of the trimer are mixed and stirred evenly, sealed and stored to obtain the curing agent component; the main agent component and the curing agent component are mixed according to a volume ratio of 1:0.7 to prepare The PU HD clear primer.

[0057] The PU high-definition transparent primer prepared in this example has good melting and dispersing of the system as a whole, has a fast drying rate, and the coating of the PU high-definition transparent primer has strong adhesion, good fullness and hardness. High, good abrasiveness, and one-time thick coating at high temperature will not cause prickly heat.

Embodiment 2

[0059] Mix 75 parts alkyd resin, 7 parts butyl ester, 7 parts propylene glycol methyl ether acetate, 15 parts filler powder, 0.2 part wetting agent, 0.2 part defoamer and 0.2 part leveling agent Stir evenly, seal and store to prepare the main agent components; mix and stir 30 parts of butyl ester, 50 parts of L-75 and 17 parts of trimer evenly, seal and store to prepare the curing agent components; the main agent The components and the curing agent components are mixed according to a volume ratio of 1:0.8 to obtain the PU high-definition transparent primer.

[0060] The PU high-definition transparent primer prepared in this example has good melting and dispersing of the system as a whole, has a fast drying rate, and the coating of the PU high-definition transparent primer has strong adhesion, good fullness and hardness. High, good abrasiveness, and one-time thick coating at high temperature will not cause prickly heat.

[0061] Compared with Example 1, 0.2 part of wetting age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com