High-nitrogen steel double-beam laser and (N-MIG) electric arc composite welding method

A hybrid welding and laser welding technology, which is applied in the field of material processing, can solve the problems of low welding efficiency, undercut of welding tumors, nitrogen loss, etc., and achieve the effects of fast welding speed, small workpiece deformation, and reduced nitrogen loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

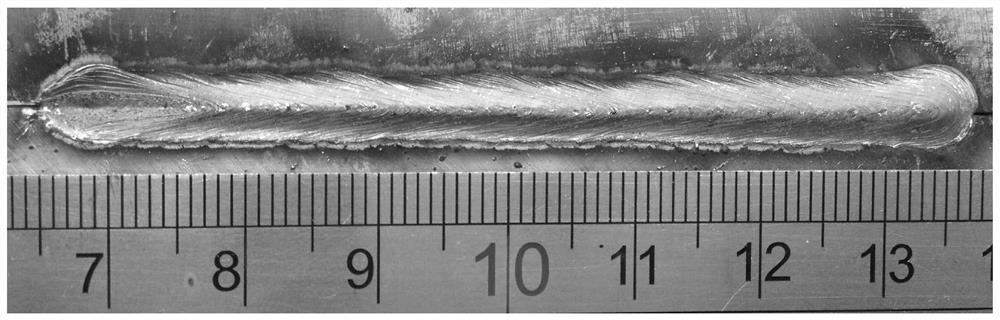

[0035] In this embodiment, the welding of 12mm thick high-nitrogen steel is taken as an example, and the double-beam laser + (N-MIG) arc hybrid welding method is used to weld it, including the following steps:

[0036] S1: Before welding, the parts to be welded are processed into I-shaped grooves, and the grooves and surfaces are cleaned, and the cleaned workpieces to be welded are clamped on the workbench;

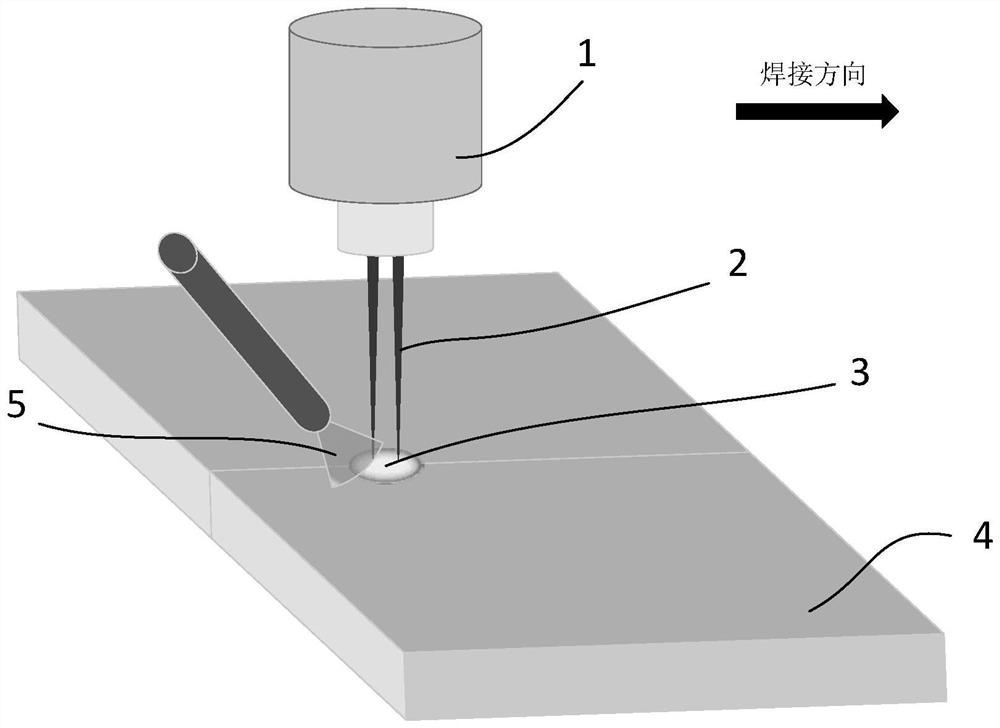

[0037] S2: Along the welding direction, the dual-beam laser heat source is positioned in front and the N-MIG arc heat source is positioned behind. The distance between the double-beam laser heat source and the N-MIG arc heat source is 2mm. The test plate is at an angle of 90°, the MIG welding torch and the workpiece to be welded are at an angle of 60°, and the double-beam welding head, the MIG welding torch and the side blowing protective gas pipe are rigidly fixed with a fixture.

[0038] S3: Set welding process parameters:

[0039] The laser power is 8kW, the power rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com