Vacuum oxygen-free heating furnace and hot stamping production line and hot stamping method thereof

A technology of heating furnace and hot stamping, which is applied in the field of vacuum anaerobic heating furnace, which can solve the problems of reducing the service life of molds, lack of extensibility, and reducing the forming performance of steel plates, so as to improve the service life of structures, reduce production processes, and reduce equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

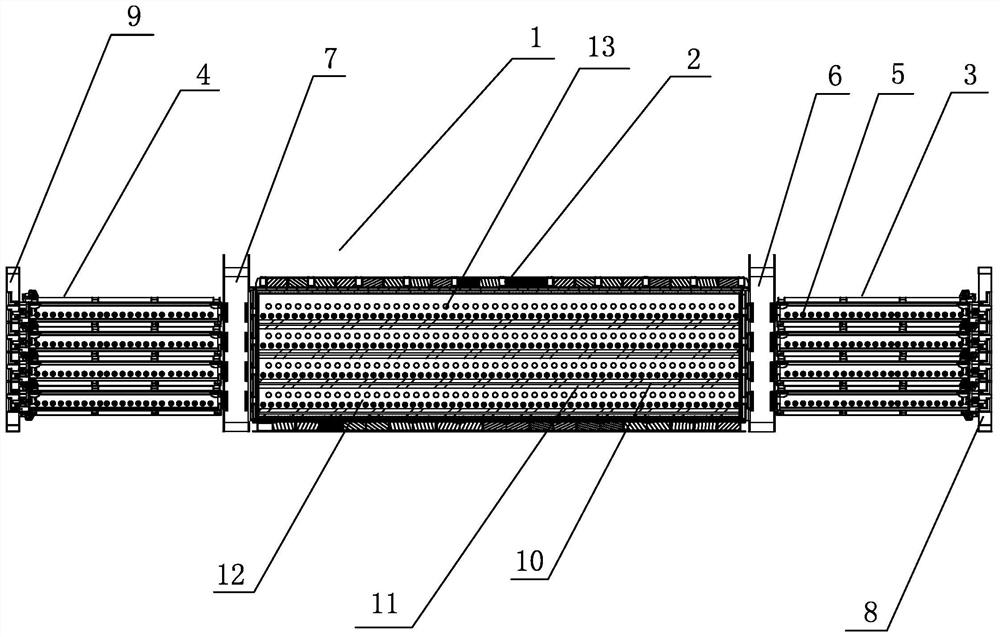

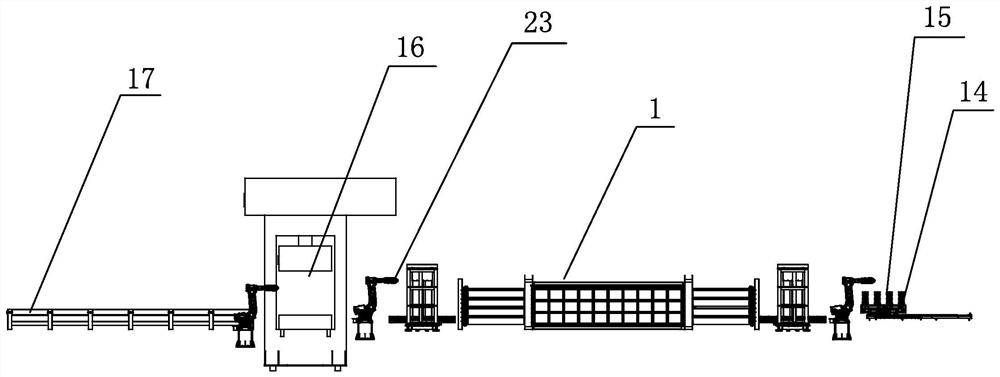

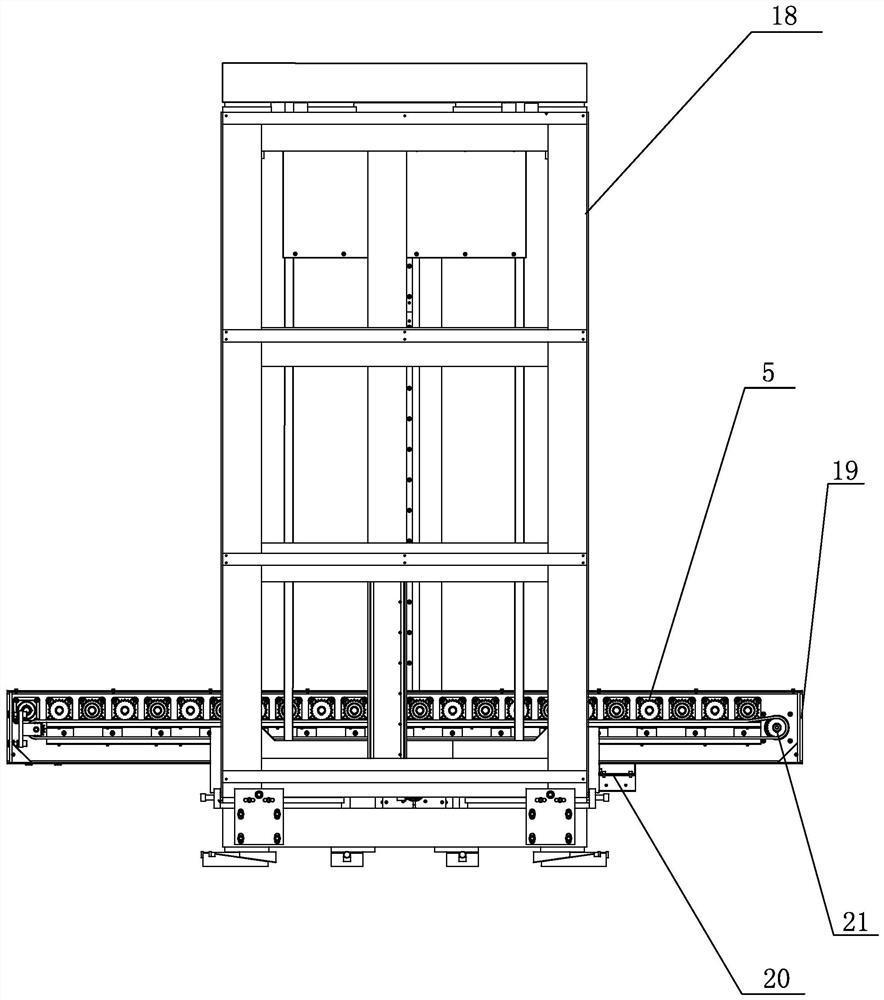

[0040] Embodiment one: see figure 1 As shown, a vacuum anaerobic heating furnace includes a hot zone 2, a cold zone, a first opening and closing mechanism, a second opening and closing mechanism, and a conveying mechanism 5, and the first opening and closing mechanism is arranged between the hot zone 2 and the Between the cold zones, the conveying mechanism 5 is used to transport workpieces between the cold zone and the hot zone 2 when the first opening and closing mechanism is in an open state, and the second opening and closing mechanism Set on the cold zone, the second opening and closing mechanism is in the closed state when the first opening and closing mechanism is in the open state, and the hot zone 2 and the cold zone are respectively equipped with corresponding Zone 2 and the cold zone are in a pressure regulating system in a vacuum anaerobic environment.

[0041] see figure 1As shown, the feeding side of the hot zone 2 is provided with a feeding cold zone 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com