Fuel cell diaphragm with good alkali resistance and high strength

A fuel cell, high-strength technology, used in fuel cells, circuits, electrical components, etc., can solve problems such as environmental protection and human health hazards, reduced battery energy conversion efficiency, and reduced proton conductivity, achieving excellent overall performance, improving Chemical stability and less device-dependent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

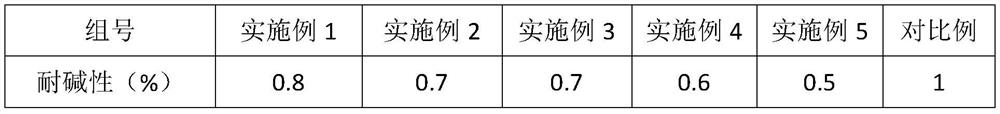

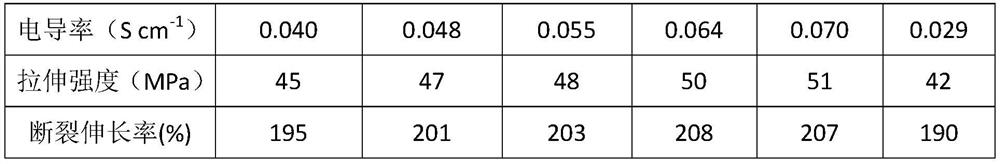

Examples

Embodiment 1

[0028] A method for preparing a fuel cell membrane, characterized in that it comprises the steps of:

[0029] Step S1, preparation of poly 2,5-piperidinedicarboxylic acid 4,4-diaminodiphenylsulfide amide: 10 g of 2,5-piperidinedicarboxylic acid, 12.4 g of 4,4-diaminodiphenylsulfide g, 4 g of phosphonothioate were added to 60 g of dimethyl sulfoxide, stirred for 40 minutes to obtain a mixed material, then the mixed material was transferred to an autoclave, and the air in the autoclave was replaced with nitrogen, and the temperature in the autoclave was maintained At 230°C, the pressure was kept at 1MPa, stirred and reacted for 3h, and then slowly exhausted and depressurized to 0.5MPa within 1 hour. Control the temperature between 225°C, stir and react for 8 hours. After the reaction, cool to room temperature, precipitate in water, and wash the precipitated polymer with ethanol for 3 times, and finally take it out and dry it in a blast drying oven at 80°C To constant weight, po...

Embodiment 2

[0035] A method for preparing a fuel cell membrane, characterized in that it comprises the steps of:

[0036] Step S1, preparation of poly 2,5-piperidinedicarboxylic acid 4,4-diaminodiphenylsulfide amide: 10 g of 2,5-piperidinedicarboxylic acid, 12.4 g of 4,4-diaminodiphenylsulfide g. Add 4.5 g of phosphorous acid to 75 g of N,N-dimethylformamide, stir for 45 minutes to obtain a mixed material, then transfer the mixed material to a high-pressure reactor, replace the air in the tank with helium, and put the high-pressure reaction Keep the temperature in the autoclave at 235°C and the pressure at 1.2MPa, stir and react for 3.5 hours, then slowly exhaust and reduce the pressure to 0.6MPa within 1.2 hours, and at the same time raise the temperature in the autoclave to 275°C, and stir for 0.6 hours. Finally, under vacuum conditions, control the temperature between 227 ° C, stir the reaction for 9 hours, after the reaction, cool to room temperature, precipitate in water, and wash th...

Embodiment 3

[0042] A method for preparing a fuel cell membrane, characterized in that it comprises the steps of:

[0043] Step S1, preparation of poly 2,5-piperidinedicarboxylic acid 4,4-diaminodiphenylsulfide amide: 10 g of 2,5-piperidinedicarboxylic acid, 12.4 g of 4,4-diaminodiphenylsulfide g, 5 g of thiophosphoramide were added to 80 g of N,N-dimethylacetamide, stirred for 50 minutes to obtain a mixed material, then the mixed material was transferred to an autoclave, and the air in the autoclave was replaced with neon gas, and the autoclaved The temperature in the reactor was kept at 240°C, the pressure was kept at 1.5MPa, and the reaction was stirred for 4 hours, and then slowly exhausted and depressurized to 0.65MPa within 1.5 hours. At the same time, the temperature in the high-pressure reactor was raised to 280°C, and the reaction was stirred for 0.8 hours. Finally, under vacuum conditions, control the temperature between 230°C and stir the reaction for 10 hours. After the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com