A kind of graphene/pyrolytic carbon/silicon carbide electromagnetic shielding composite material and preparation method thereof

A technology of electromagnetic shielding and composite materials, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of lack of structure and function, poor mechanical structure performance, etc., and achieve ultra-high mechanical structural performance, super electromagnetic shielding characteristics, Effect of excellent electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

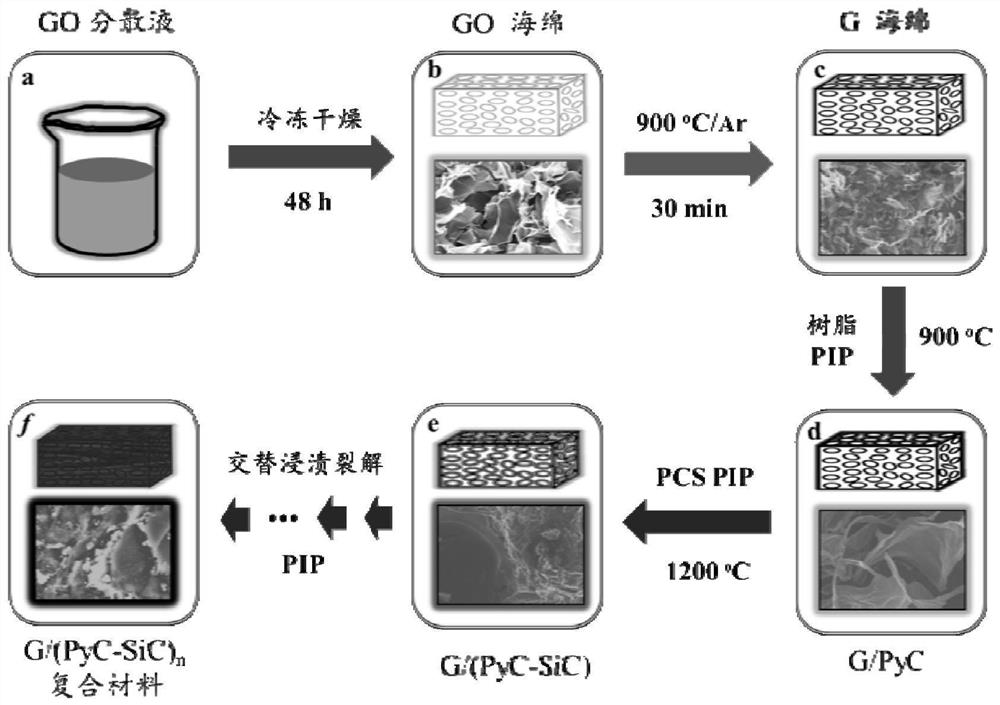

[0036] The preparation method of a graphene / pyrolytic carbon / silicon carbide electromagnetic shielding composite material provided by the invention comprises the following steps:

[0037] Step 1, Preparation of Graphene Oxide (GO)

[0038] Slowly add 1-5 g of graphite powder and 0.5-2 g of sodium nitrate into 30-150 mL of concentrated sulfuric acid to obtain a mixture, which is placed in an ice-water bath at 0°C and mixed uniformly; then slowly add 3-20 g of potassium permanganate, Make it fully stirred in a 35°C water bath to obtain a strong oxidizing concentrated sulfuric acid / potassium permanganate / sodium nitrate-graphite mixture;

[0039] Then slowly add the concentrated sulfuric acid / potassium permanganate / sodium nitrate-graphite mixture into 30-150 mL of deionized water to obtain a dilution with a concentration ratio of the mixture to deionized water of 1;

[0040] The diluted product is then placed in a 90°C water bath to fully react for 30 to 60 minutes to obtain the ...

Embodiment 1

[0058] Step 1, preparation of graphene oxide (GO);

[0059] Weigh 1g of graphite powder and 0.5g of NaNO respectively 3 , which were successively added to 30 mL of concentrated H 2 SO 4 , the mixture was placed in an ice-water bath at 0°C and stirred well, and then 3g KMnO was slowly added. 4 , and then placed in a 35°C water bath to stir and react for 30min, then added to 30mL of deionized water, and reacted in a 90°C water bath for 15min. After the reaction was over, slowly add 5 mL of H with a mass concentration of 30%. 2 O 2 solution, let stand for a period of time, remove the lower layer of sediment, wash it by centrifugation with ethanol and water until the pH value is 5-7, and take the lower layer of sediment to be GO;

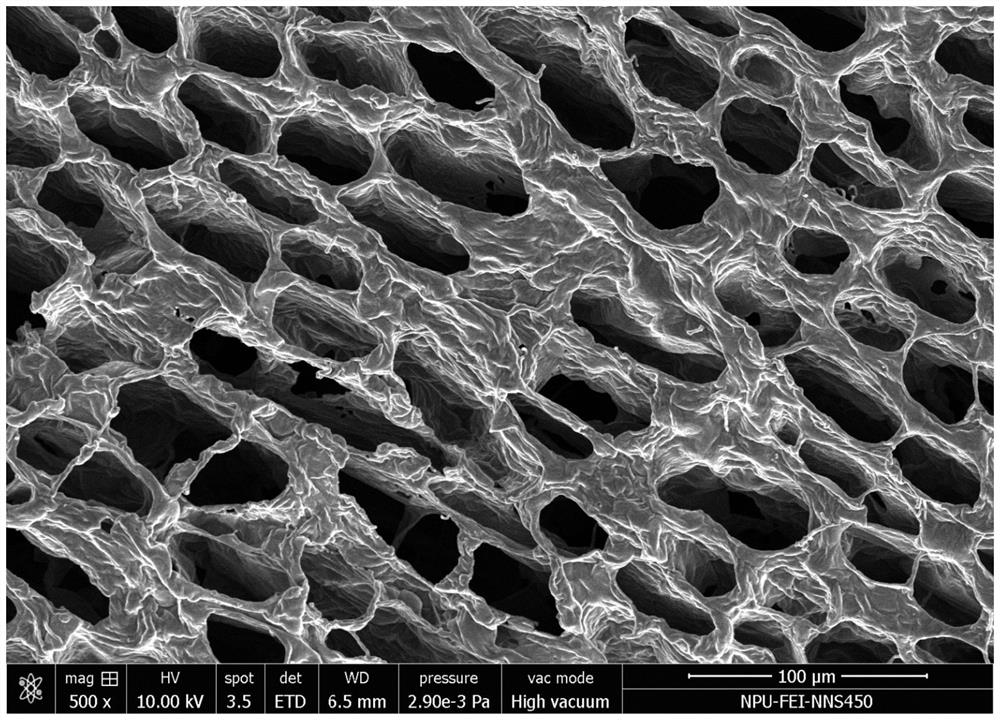

[0060] In step 2, the prepared GO was added with water to prepare a dispersion with a concentration of 3 mg / mL, ultrasonically treated for 3 hours, then frozen for 24 hours, and then freeze-dried for 48 hours to obtain a GO sponge three-dimensional ...

Embodiment 2

[0066] In step 1, graphene oxide is prepared in the same manner as in the first step of Example 1.

[0067] Step 2, adding water to the prepared graphene oxide to prepare a dispersion with a concentration of 3 mg / mL, ultrasonically treating it for 3 hours, freezing it for 24 hours, and then performing freeze-drying treatment for 48 hours to obtain a GO sponge three-dimensional framework.

[0068] In step 3, the prepared GO sponge three-dimensional skeleton is placed in a tube furnace, and the temperature is raised to 900° C. under nitrogen protection for 30 minutes of high temperature heat treatment to obtain a G sponge.

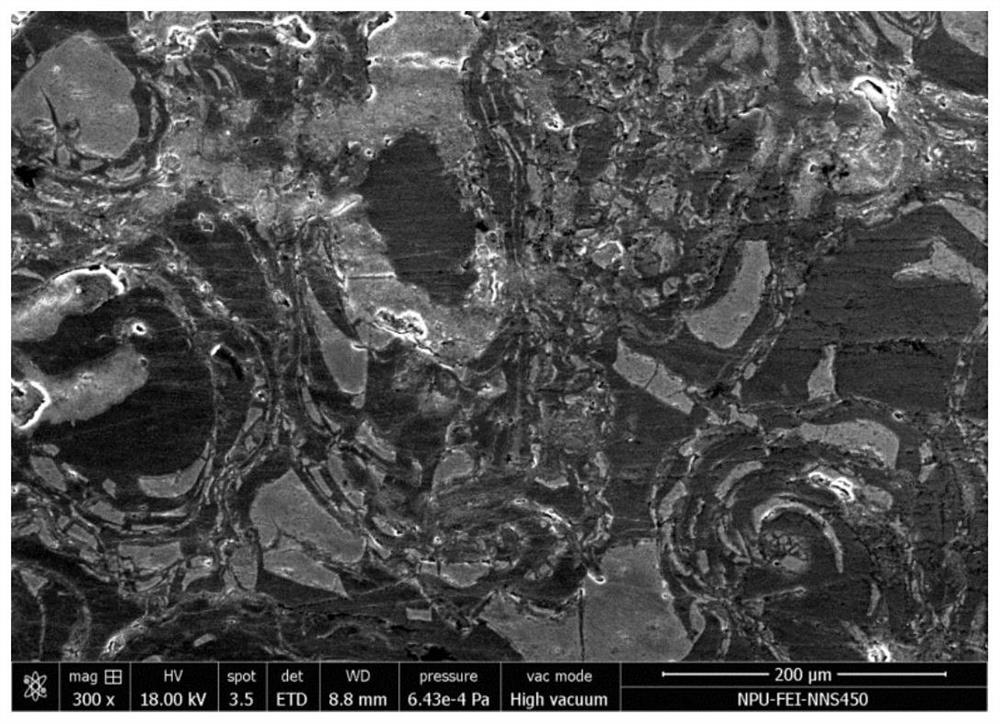

[0069] Step 4: Immerse the prepared G sponge in an ethanol solution with a mass fraction of 50% resin for 30 minutes, then place it in an oven for curing, and heat it up to 120° C. for 3 hours at 1° C. / min. Finally, it was put into a tube furnace for high temperature cracking with nitrogen gas, the cracking temperature was 900 °C, and the time was 2 hours; i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com