Preparation method for synthesizing ultra-slow-release polycarboxylate superplasticizer from high-activity polyether

A technology of slow-release polycarboxylic acid and high-activity polyether, which is applied in the field of building material production, can solve the problems of long production cycle, short slow-release time, low reactivity, etc., and solve the problems of excessive collapse and open operation time , high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

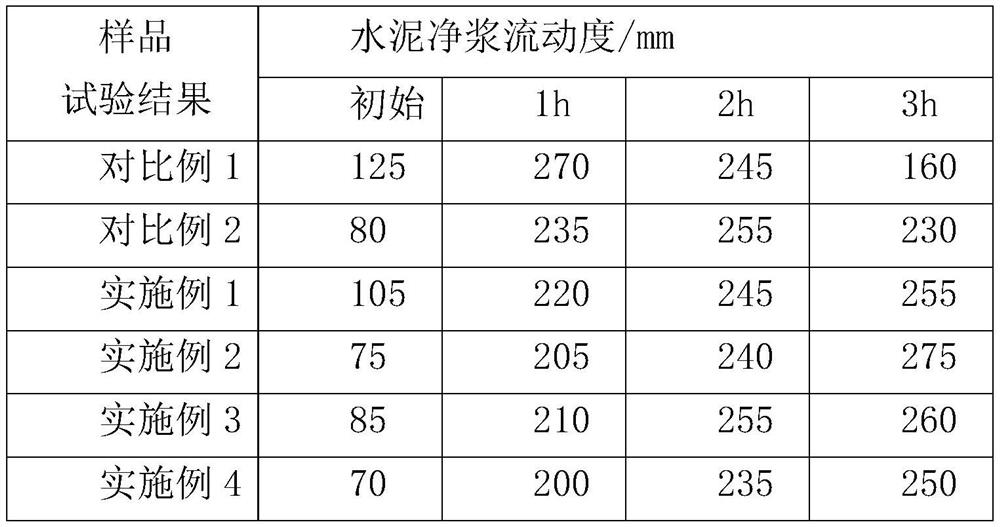

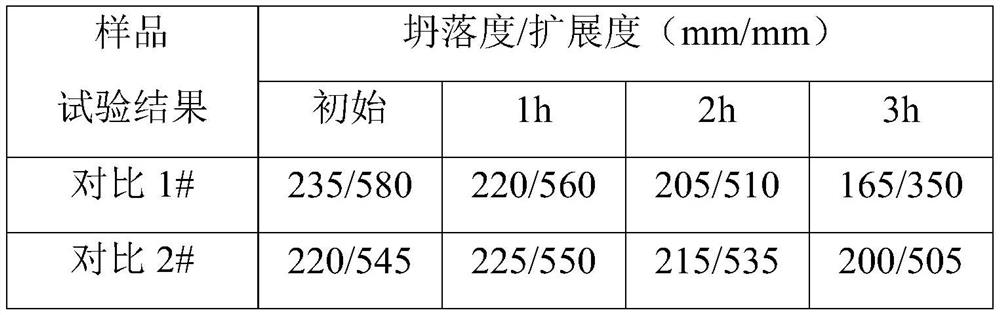

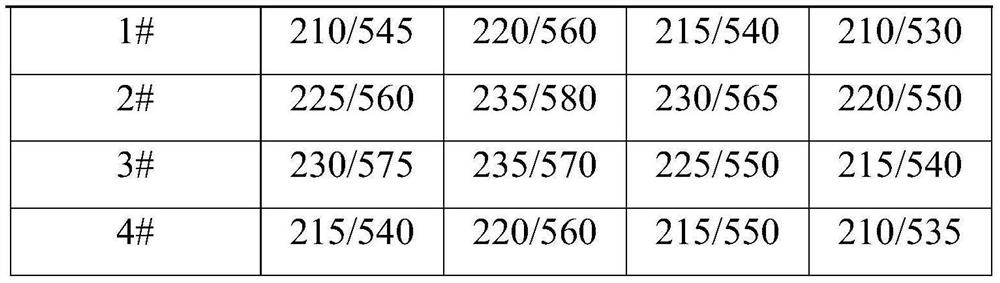

Examples

Embodiment 1

[0027] S1: Adding solutions A and B: Mix 15 parts of acrylic acid, 20 parts of hydroxyethyl acrylate, 15 parts of hydroxypropyl acrylate, 35 parts of dimethyl fumarate, 2.5 parts of thioglycolic acid, and 55 parts of deionized water As dripping solution A; mix 2 parts of sodium bisulfite and 60.5 parts of deionized water evenly as dropping solution B, and set aside;

[0028] S2: Add 270 parts of deionized water and 300 parts of EPEG3000 monomer into the reactor, stir at room temperature to fully dissolve, adjust the temperature to 10°C, add 3 parts of acrylic acid to adjust the acidity of the bottom solution, and stir evenly;

[0029] S3: At the initial temperature of 10°C, add 5 parts of 1% ferric chloride solution and 3 parts of ammonium persulfate to the mixed solution obtained in step S2, stir for 5 minutes and start adding liquid A and liquid B at a constant speed, and add liquid A dropwise 50min, B solution was added dropwise for 60min, during which the temperature of th...

Embodiment 2

[0032] S1: Adding solutions A and B: Mix 15.5 parts of acrylic acid, 20.5 parts of hydroxyethyl acrylate, 13 parts of hydroxypropyl acrylate, 40 parts of dimethyl maleate, 1.5 parts of mercaptopropionic acid, and 55 parts of deionized water Uniformly used as dripping solution A; mix 0.9 parts of L-ascorbic acid and 81.5 parts of deionized water evenly as dropping solution B, and set aside;

[0033] S2: Add 250 parts of deionized water and 300 parts of EPEG3000 monomer into the reaction kettle, stir at room temperature to fully dissolve, adjust the temperature to 15°C, add 2.5 parts of acrylic acid to adjust the acidity of the bottom solution, and stir evenly;

[0034] S3: At the initial temperature of 15°C, add 2 parts of 1% ferrous sulfate solution and 3 parts of 30% hydrogen peroxide to the mixed solution obtained in step S2, stir for 5 minutes and start adding liquid A and liquid B dropwise at a constant speed, and add liquid A dropwise 60min, B solution was added dropwise ...

Embodiment 3

[0037] S1: Adding solutions A and B: Mix 16 parts of acrylic acid, 23 parts of hydroxyethyl acrylate, 12 parts of hydroxybutyl acrylate, 36 parts of dimethyl maleate, 1.5 parts of mercaptopropionic acid, and 55 parts of deionized water Uniformly used as dripping solution A; mix 1.2 parts of L-ascorbic acid and 89.5 parts of deionized water evenly as dropping solution B, and set aside;

[0038] S2: Add 300 parts of deionized water and 360 parts of EPEG3600 monomer into the reactor, stir at room temperature to fully dissolve, adjust the temperature to 15°C, add 2 parts of acrylic acid to adjust the acidity of the bottom solution, and stir evenly;

[0039]S3: At the initial temperature of 15°C, add 2 parts of 1% ferrous sulfate solution and 2.5 parts of 30% hydrogen peroxide to the mixed solution obtained in step S2, stir for 5 minutes and start adding liquid A and liquid B at a constant speed, and liquid A is added dropwise 50min, B solution was added dropwise for 60min, during ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com