High-specific-energy lithium battery electrode, dry preparation method thereof and lithium battery

A lithium battery, high-ratio technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, electrode manufacturing, etc., can solve the problems of high demand for binder, reduced capacity efficiency, and high proportion of inactive materials, saving processing. Process steps, ensuring electrochemical performance, and the effect of good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

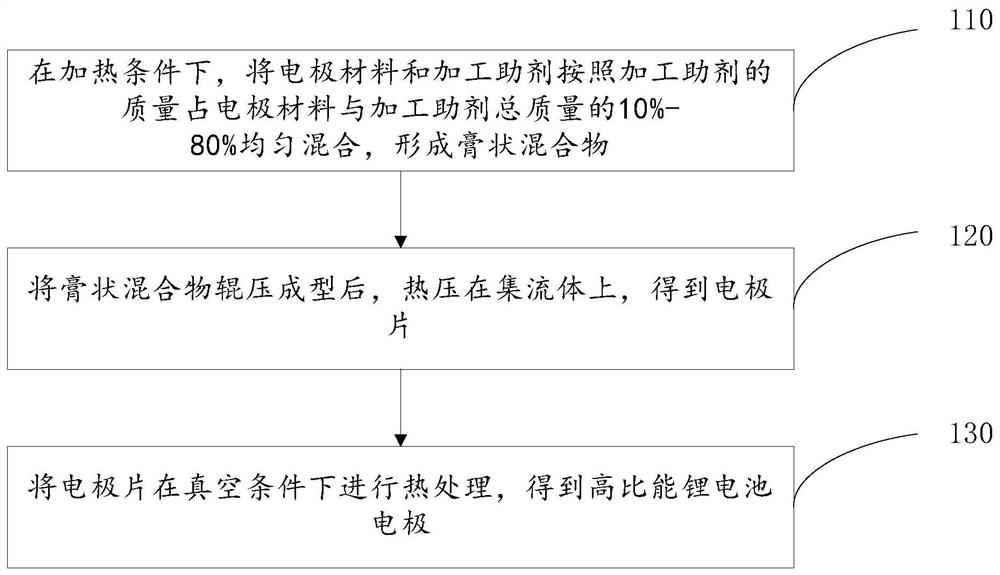

[0031] The dry preparation method of the high specific energy lithium battery electrode of the present invention is used for dry preparation of lithium battery electrodes, that is, it can be used for the preparation of positive electrodes and the preparation of negative electrodes. The main preparation process is as follows: figure 1 shown, including the following steps:

[0032] Step 110, under heating conditions, uniformly mix the electrode material and the processing aid according to the mass of the processing aid accounting for 10%-80% of the total mass of the electrode material and the processing aid to form a paste mixture;

[0033] Among them, the electrode material includes: electrode active material, conductive agent, binder;

[0034] Electrode active materials include positive electrode active materials or negative electrode active materials;

[0035] The positive electrode active material includes: one or a combination of nickel-cobalt lithium manganese oxide, lith...

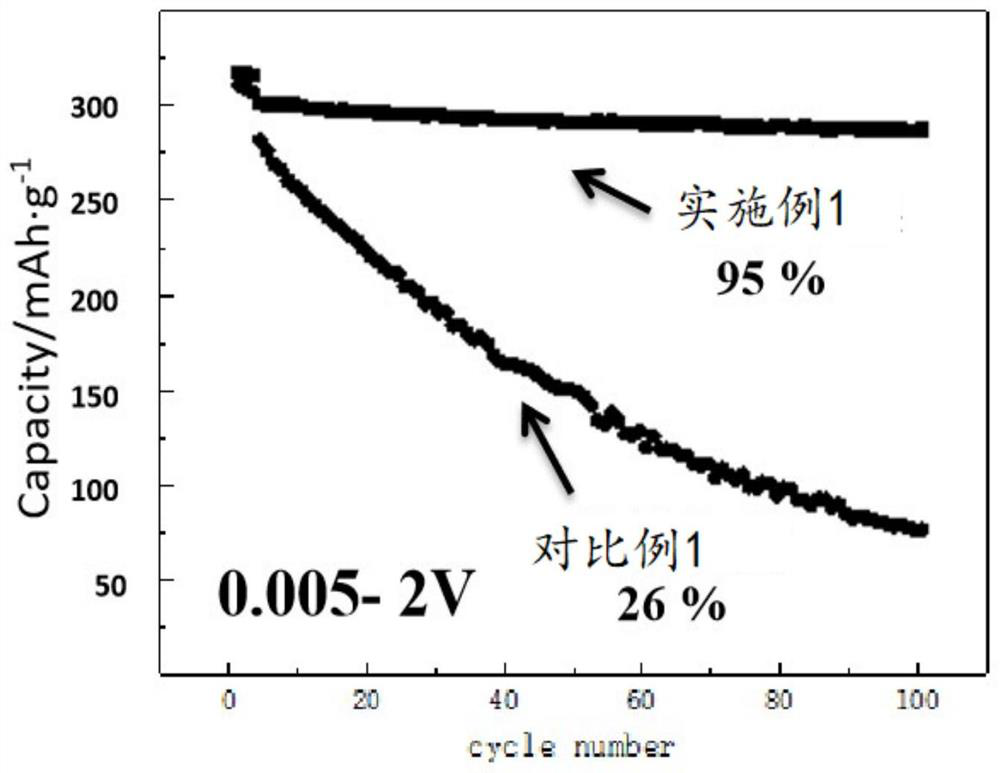

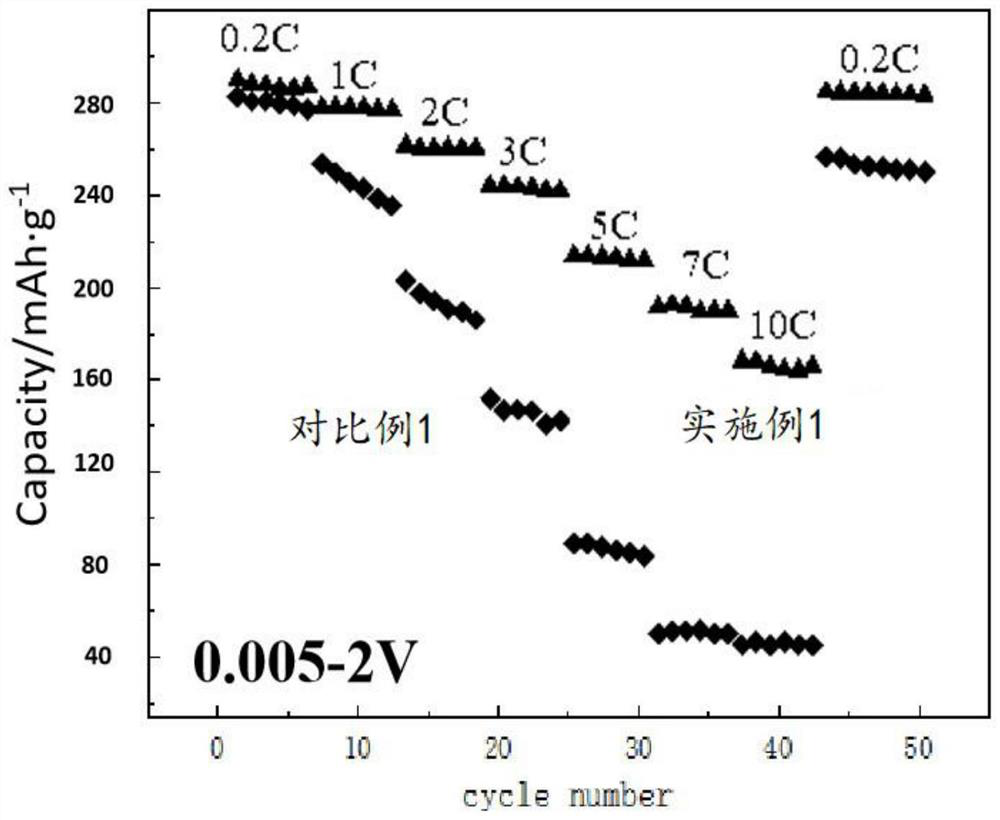

Embodiment 1

[0051] This embodiment provides a solvent-free dry preparation process for high specific energy lithium battery electrodes, including the following steps:

[0052] Under the condition of 60°C, artificial graphite, conductive carbon black, carbon nanofiber and styrene-butadiene rubber were simply mixed in a planetary ball mill at 2000rpm according to the mass ratio of 80:10:5:5, and 80 parts of polyvinyl carbonate ( PEC) after stirring at the same speed for 1 hour, the resulting homogeneous mixture was roll-formed under a pressure of 600 psi, and the thin material obtained by rolling was hot-pressed on a copper foil at 45° C. and a pressure of 35 psi to obtain a negative electrode sheet. The negative electrode sheet was gradually heated up to 230° C. under vacuum conditions to prepare the negative electrode sheet.

[0053] The processing aid polyethylene carbonate (PEC) used in this embodiment has an extremely low glass transition temperature (0-10° C.), which can reduce the te...

Embodiment 2

[0066] This embodiment provides a solvent-free dry preparation process for high specific energy lithium battery electrodes, including the following steps:

[0067] Under the condition of 80°C, the artificial graphite negative electrode material, conductive carbon black, carbon nanofiber and styrene-butadiene rubber are simply mixed in a planetary ball mill at 3000rpm according to the mass ratio of 72.5:15:5:7.5, and 90 parts of polyethylene carbonate are added After the ester (PEC) was stirred at the same speed for 2 hours, the resulting homogeneous mixture was roll-formed under a pressure of 800 psi, and the thin material obtained by rolling was hot-pressed on a copper foil at 45 ° C and a pressure of 35 psi to obtain a negative electrode sheet. Finally, the temperature of the negative electrode sheet was gradually raised to 230° C. under vacuum conditions to obtain the negative electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com