Positive electrode slurry, preparation method thereof, positive electrode sheet and lithium ion battery

A technology of positive electrode slurry and positive electrode sheet, which is applied in the field of battery preparation, can solve the problems of difficult dispersion, prolonged stirring time, poor dispersion effect, etc., and achieve the effect of excellent electrochemical performance and high capacity density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

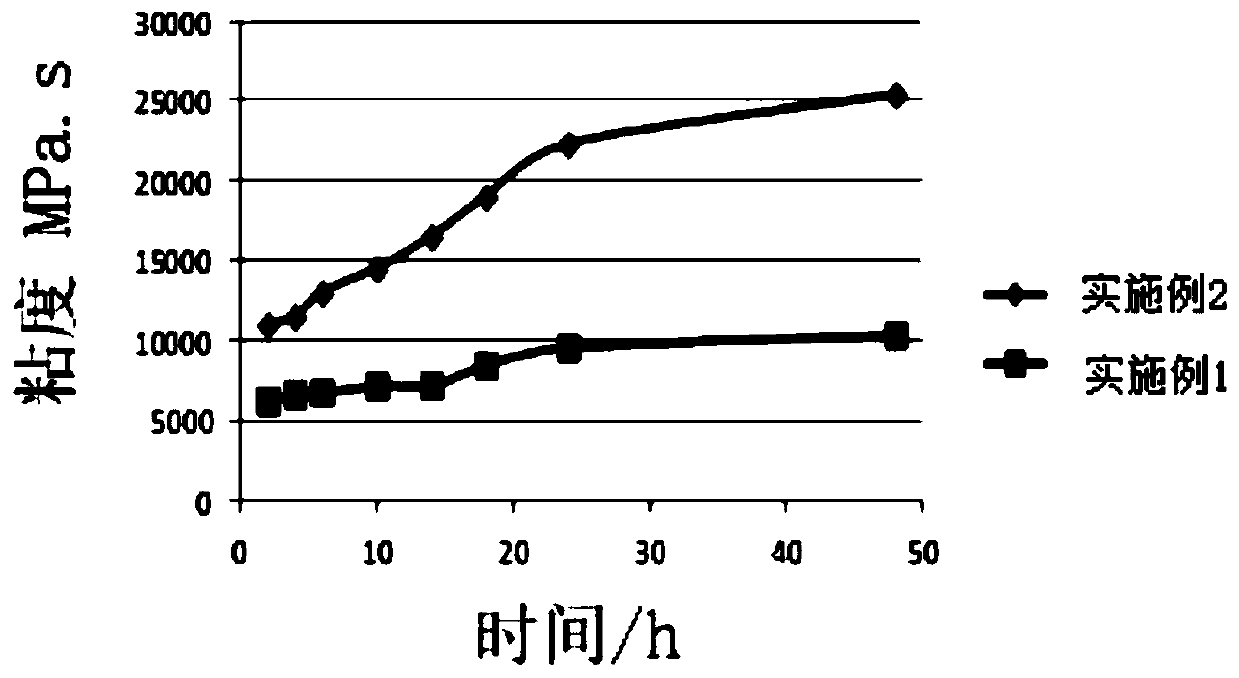

Embodiment 1

[0040] Laboratory scale: ambient temperature is 2523°C, humidity≦40%RH

[0041] (1) Add 9,000 g of polyvinylidene fluoride into the mixer, and then add 184.62 g of lithium iron phosphate active material, and stir for 30 minutes at a speed of 35 rpm for revolution and 2,000 rpm for autorotation.

[0042] (2) Add 923.08 g of carbon nanotubes, and stir for 30 minutes at a speed of 35 rpm for revolution and 2500 rpm for autorotation.

[0043] (3) Add 2063.35g of N-methylpyrrolidone, stir for 30min at a speed of 35 rpm with revolution and 2200 rpm with rotation, and measure the solid content of the slurry at this time to be 75%, see the slurry state diagram figure 1 Middle a.

[0044] (4) Add 1737.50 g of N-methylpyrrolidone, and stir for 120 min at a speed of 35 rpm for revolution and 2200 rpm for autorotation.

[0045] (5) Add 2353.00 g of N-methylpyrrolidone, and stir for 120 min at a speed of 35 rpm and 2200 rpm for rotation to obtain the positive electrode slurry of Example ...

Embodiment 2

[0050] On the basis of Example 1, the production scale is enlarged by 10 times, and the ambient temperature is 2523°C, humidity≦40%RH

[0051](1) Add 90 kg of polyvinylidene fluoride into the mixer, then add 1846.2 lithium iron phosphate active material, and stir for 30 minutes at a speed of 35 rpm for revolution and 2000 rpm for autorotation.

[0052] (2) Add 9230.8 g of carbon nanotubes, and stir for 30 minutes at a speed of 35 rpm for revolution and 2500 rpm for rotation.

[0053] (3) Add 20 kg of N-methylpyrrolidone, stir for 30 minutes at a speed of 35 rpm for revolution and 2200 rpm for rotation, and measure the solid content of the slurry at this time to be about 75%.

[0054] (4) Add 17 kg of N-methylpyrrolidone, and stir for 120 min at a speed of 35 rpm for revolution and 2200 rpm for autorotation.

[0055] (5) Add 23kg of N-methylpyrrolidone, stir for 120min at a speed of 35 rpm with revolution and 2200 rpm with rotation, to obtain the positive electrode slurry of E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com